Faculty Profile: Dr. Janelle Wharry's passion for Nuclear Engineering impacts student development.

Wharry’s research surrounds the micromechanical behavior of the materials under radiation. When examining the mechanical properties of a material (strength, ductility, and resistance to fracture) often times these items are quantified and talked about on a large-scale. But these “bulk" or macroscale behaviors are actually governed by atomic/microscopic level features in the materials. Building the connection between the atomic and macro scales is exactly what Wharry and her team are trying to figure out – and with an emphasis on how radiation can change those relationships.

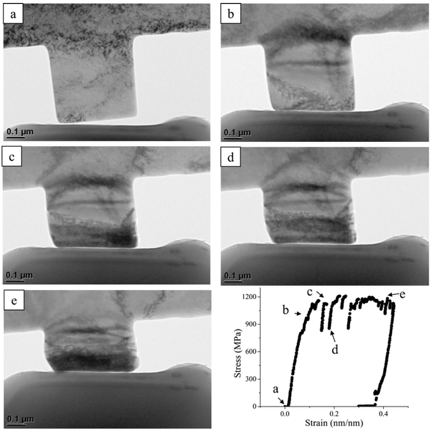

One unique testing approach that Wharry and her team are pioneering is that of conducting a mechanical test on a specimen only a few hundred nanometers in size (a few 10,000ths of a millimeter) as shown in Figure 1. These tests can be compared to conventional standards-based mechanical tests, which call for specimens a few centimeters in size. The Wharry group’s tests, then, have the distinct advantage that their volume is so small that they can safely be used on radioactive materials. Currently, the group is implementing these micromechanical testing approaches on a variety of nuclear-relevant materials, including stainless steel weld repairs (e.g. baffle bolts) and advanced oxide dispersion strengthened alloys.