Professor Luna Lu engages students as she develops self-healing concrete

Tackling the freeze-thaw problem to improve Midwest roads

For drivers in the Midwest, the problem with winters isn't simply the cold. It's the dreaded freeze-thaw cycle that erodes, cracks and pits road surfaces.

After a rainy period, water saturates concrete road surfaces. If temperatures fall below 32 degrees F, the water molecules freeze, expanding by as much as 9%, and crack the concrete. Over the course of several winters, fissures in the road surface grow large enough to allow de-icing chemicals to seep in — and, in bridge decks, these chemicals will reach the steel rebar substructure and corrode it. In states like Indiana that experience the freeze-thaw cycle, winter leads to costly repairs.

Luna Lu, associate professor of civil engineering and American Concrete Pavement Association Scholar

Addressing the freeze-thaw cycle

In the Lyles School of Civil Engineering, Na “Luna” Lu, associate professor and ACPA Scholar, is exploring formulations for self-healing concrete, a construction material that will last longer in regions prone to the freeze-thaw cycle. For Lu, undergraduate students are an integral component to this and other research projects.

“Our objective with this project is to develop cost-effective methods that give concrete the ability to self-heal during the winter cycle,” she says. “We are looking at rehealing cracks up to 50 microns, 80 microns, less than 100 microns.” A human hair is about 75 microns thick.

Working with the Indiana Department of Transportation, the team is putting its primary focus on bridge decks. “They are large concrete slabs, and they have significant thermodynamic expansion. Also, bridge decks typically undergo a large deflection, so it’s easier for them to develop cracks,” Lu says. “Our hope is that by using a self-healing material in bridge decks, we can significantly cut down on the repairs needed.”

The team sees promise with a class of materials called super-absorbent polymers (SAP). Regular cracked concrete has a limited ability to self-heal, but when mixed with SAP, the cracked concrete has a lower water permeability as the SAP swells when water enters a crack, blocking the crack and “healing” it. The healing process produces chemicals, basically calcium composites, that seal the crack.

Hands-on undergraduates

“Regardless of the career path a student may take, to graduate school or into industry, this type of independent study — which involves critical thinking, developing solutions to open-ended questions — this skill set is very important. That’s No. 1,” Lu says. Hands-on research also makes science more direct. “For instance, in class we talk about things like the hydration process and the hydrogen curve. It can sound very abstract, but working on a research project like this helps students understand the tangible applications of science.”

Working in Lu’s lab, civil engineering junior Alex Kellam has gained fundamental knowledge about the behavior of concrete. “Just understanding that concrete is inherently self-healing was insightful,” he says.

Kellam tested how SAP compounds respond to the effects of shearing, which occurs during the mixing process. In the lab, his job was to mix concrete “recipes” with different mixing speeds and durations.

“When you see a concrete truck, it’s constantly spinning, shearing, in effect,” Kellam says. “It keeps the concrete fluid and keeps it from hardening, but we wanted to know the effects of the shearing on the polymer to make sure that it wasn’t going to reduce the amount it can absorb, or change it in some other way.”

Junior Alicia Tunggal works on a different problem. Using the tea bag filtration method, she’s gathering data on the rate of absorption for different types of super-absorbent polymers.

She says she was a little surprised by the research experience.

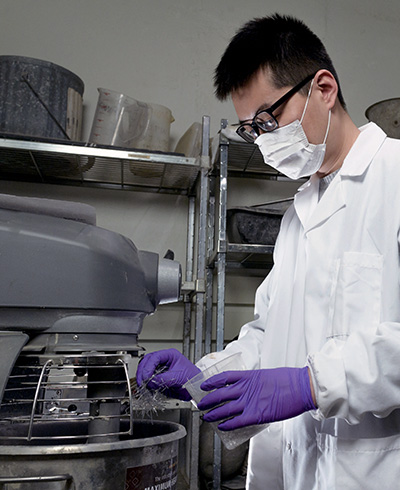

Siwei Ma, postdoctoral scientist, tests SAP compounds for optimum use in self-healing concrete.

Improving the industry

“In engineering, I always thought we’re trying to solve problems,” Tunggal says. “But it’s more. After working with Professor Lu and the graduate students, I can see they are actually thinking about ways to improve the construction industry. So, even the little things we do are useful and are actually helping to make an impact in the engineering field — and on society.”

The undergrads in Lu’s lab work under the supervision of Siwei Ma, a postdoctoral scientist interested in self-healing concrete materials. He enjoys the collaborative aspects of working with undergraduates. “For example, while conducting an experiment with Alex, he mentioned Pykrete,” Ma says. “It’s a composite material made of ice and sawdust I had not heard of, and it has mechanical properties comparable to conventional concrete. It’s an idea I’m still thinking about. These kinds of interactions in the lab are inspirational.”