Extraordinary Experiences

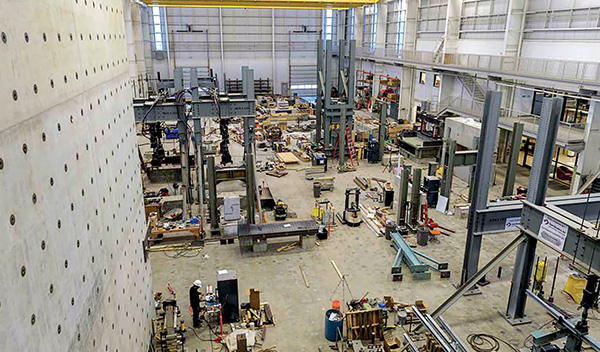

"It was a little intimidating starting off as an undergraduate research assistant at Purdue's Bowen Laboratory," says David Derks. The feeling is understandable. Inside the 66,000-square-foot building, the concrete walls rise 54 feet high, about five stories. A catwalk extends along the south wall. And situated throughout the expansive floor plan are heavy machinery, overhead cranes, instrumentation stations — and structural specimens in various stages of construction and testing. Everyone on the floor wears a hard hat, eye protection and gloves, as needed.

Large-scale research

Since 2013, civil engineering research faculty at Purdue have used the lab and its technical capabilities to investigate the behavior of large-scale and full-scale structural models: bridge beams and decks, walls and slabs, steel columns and frames. Specimens are subjected to extreme loads, such as simulated earthquakes, blasts and impact, so that future structures can be designed to better withstand these events as well as the stress of time.

As an undergraduate, David Derks had a good understanding of engineering concepts from his classes, but he was curious to learn more. “I was a little timid as far as approaching graduate students and faculty and asking questions,” he says. “Then as I settled in and got to know everyone better, they became great resources for learning — about the research process and the behavior and strength of reinforced concrete.”

Chris Williams, assistant professor of civil engineering and Derks’ advisor and mentor, specializes in large-scale reinforced concrete structures. Williams says having access to the Bowen Lab is a huge advantage for civil engineering students seeking research experiences.

"Just the structural capacity of the strong floor and the strong wall — they allow us to apply extreme forces to structural components. At Bowen, we have the size to do large-scale and even full-scale testing of structural components,” Williams says. “If we want to test a bridge beam, we can just bring the bridge beam into the lab and test it, no problem.”

Learning by doing

Students working at Bowen have a chance to get their hands dirty and to handle the materials they learn about in the classroom. “I think concepts make a lot more sense to students when they see and touch them in the lab,” Williams says. Plus, student researchers have a chance to gauge their interest in certain areas, to see if working with large structures is something they want to continue.

Derks, now working on his master’s degree, has been getting his hands dirty in the Bowen Lab since the summer after his sophomore year.

He learned about post-tensioning and prestressed concrete by helping a graduate student test bridge beams with post-tensioned steel strands inside them. He helped prestress the anchoring rods used to secure the test setup.

In another instance, he learned to mix and apply mortar to repair a giant bridge I-beam with a gap in the end section. “We also had to build elevated formwork around another gap on the top, then pour high-slump concrete to fill it. I’d never done elevated formwork like that.”

He has proven valuable to researchers who need an experienced assistant — to help set up load tests, for example. Working on a bridge deterioration project last year, Derks helped move giant box beams, weighing several thousand pounds apiece, and place them in a test setup with loading equipment positioned to press down on each beam. “I had to get up on ladders and, with a pressurized impact hammer drill, bolt the steel test station together.”

Then he helped attach the hydraulic presses (which push down on the specimen) and load cells (which enable researchers to measure the force) to the overhead setup. Putting the beams in place required both of Bowen’s overhead cranes. Fortunately, the lab manager handled that task.

Derks enjoys hands-on engineering, although he knows it is not for everyone. “It’s hard work. You’ll leave every day covered in dirt, or steel grease or sawdust. But if you like this kind of work, then it’s rewarding,” he says. “If you immerse yourself in the work and ask lots of questions, you can learn a lot from graduate researchers and their projects.”

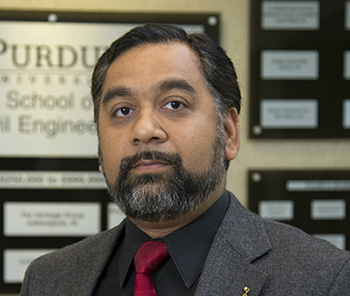

Amit Varma

Bowen Laboratory honored with ACI's Charles S. Whitney Medal

The Bowen Lab has been named the 2020 recipient of the American Concrete Institute’s Charles S. Whitney Medal. Charles Whitney (1892-1959) was world-renowned for his innovations in concrete construction and bridge building. The Bowen Lab was recognized for its researchers’ consistent contribution to the economy and safety of buildings and infrastructure.

“Winning the Whitney Medal is a tremendous honor,” says Amit Varma, the Karl H. Kettelhut Professor of Civil Engineering and Director of the Bowen Laboratory of Large-Scale CE Research. “The ACI rarely confers the Whitney Medal on a research and testing laboratory, so we feel especially gratified to be recognized. Our faculty, staff and students look forward to making pioneering and innovative contributions toward improving the safety and economy of buildings and the built infrastructure.”