A Multidisciplinary Effort

Geotechnical engineering and soil chemistry researchesr pursue long-term solution for oil sand tailings

A multidisciplinary effort between Purdue University's Lyles School of Civil Engineering and the Departments of Agronomy and Earth, Atmospheric, and Planetary Sciences aims to contribute to the design of practical engineering solutions for the safe long-term management of Canada’s oil sands tailings ponds.

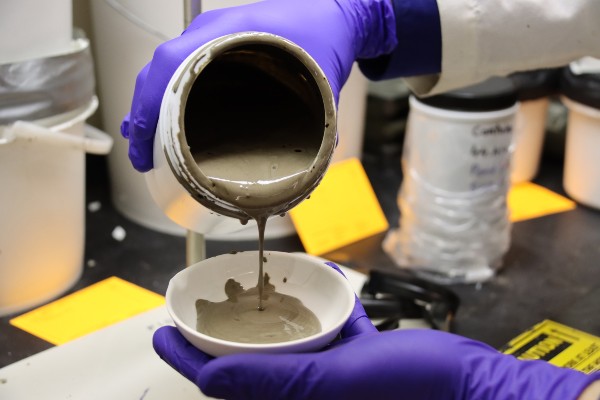

Tailings ponds are engineered dam and dyke facilities used to store fluid fine tailings. These tailings are high water content waste byproducts of oil sands mining. Currently, there are more than 1 billion cubic meters of fluid fine tailings in northern Alberta. And with each passing year, the volume of these ponds only continues to grow.

“Right now, the volume of tailings could just about canvas all of Chicago,” said Cliff Johnston, professor of soil chemistry. “These tailings are like a milkshake made of around 30 percent clay and 70 percent water with organic materials in it. You can literally see these ponds from space.”

One of the most effective paths to improving the situation involves treating these tailings with water-soluble polymers to accelerate their dewatering for final integration into reclaimed landscape. “Despite the wide application of this methodology, the mechanisms that control the effectiveness of the treatment are not completely understood, and many questions remain regarding the long-term properties of the unique geomaterial created as a result of the treatment” said Marika Santagata, associate professor of civil engineering.

Mohammadhasan Sasar, a geotechnical engineering PhD student, explained that this is due to “the complex and variable nature of the tailings, and the many factors that come into play, including water chemistry, type and amount of polymer added and amount of mixing energy applied in the field.”

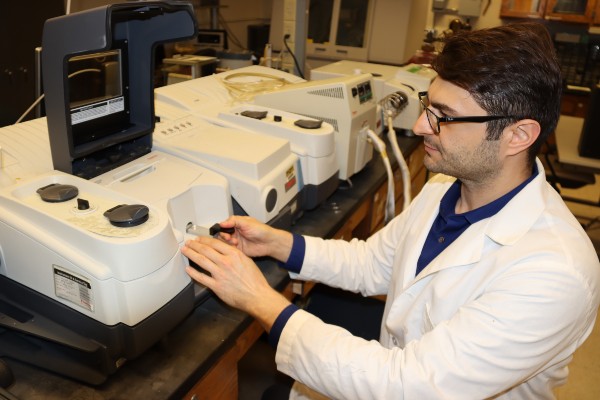

Sasar has been working with Santagata and Johnston on understanding the interplay that exists between the chemistry of the polymer treated tailings and their short-term and long-term structure and engineering properties. The complex nature of the research required an incredible amount of cooperation between departments.

“Without the interdisciplinary efforts between our group in civil engineering and the soil chemistry laboratory in the Department of Agronomy, this would have been far too complex of an issue to tackle,” Santagata said. “Study of polymer-clay-organic interactions, and characterization of these ultra-soft geomaterials required expertise in multiple disciplines.”

The research team is now working to share their results with the professional community.