Improving the safety of nuclear power

New deep-learning system detects cracks in nuclear power plant infrastructure

Purdue Civil Engineering researchers have developed an automated system that detects cracks in the steel components of nuclear power plants — and it has already proven to be more accurate than its predecessors.

“Periodic inspection of the components of nuclear power plants is important to avoid accidents and ensure safe operation,” says Mohammad R. Jahanshahi, assistant professor of civil engineering. “However, current inspection practices are time-consuming, tedious and subjective because they involve an operator manually locating cracks in metallic surfaces.”

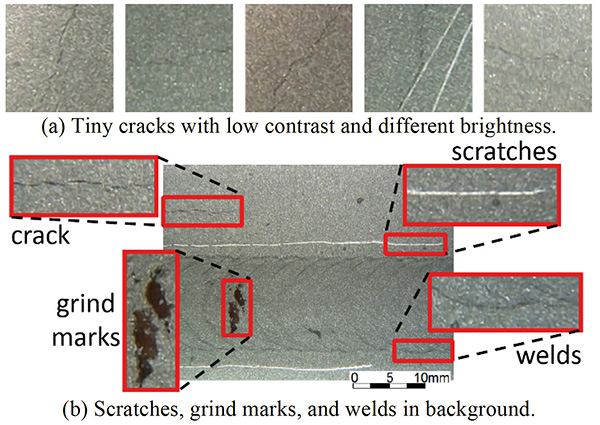

Other automatic crack detection algorithms under development often do not detect cracks in metallic surfaces because the cracks are usually small, have low contrast and are difficult to distinguish from welds, scratches and grind marks.

In 2016, Jahanshahi and his team developed a crack detection system called CRAQ that overcame these limitations by using a texture analysis approach. Subsequently, the team developed a new version of CRAQ based on an advanced algorithm and a powerful “deep learning” technique to detect cracks on steel surfaces using a convolutional neural network, data fusion, statistics and Bayesian probability. The new version significantly outperforms its predecessor.

The United States operates 99 commercial nuclear power plants, which account for about 20 percent of total U.S. electricity generation. Aging materials in the structures suffer cracking, fatigue, embrittlement of metal components, wear, erosion, corrosion and oxidation.

“Cracking is an important factor in aging degradation that may cause leaking and result in hazardous incidents,” Jahanshahi says. “For instance, the Millstone Nuclear Power Station in Connecticut had an accident in 1996 that was caused by a leaking valve, and the accident cost $254 million. In 2010, the Vermont Yankee Nuclear Power Plant had an accident where deteriorating underground pipes leaked radioactive tritium into groundwater supplies, resulting in $700 million in damage.”

The inspection process is challenging because nuclear reactors are submerged in water to maintain cooling. In addition, other automated crack-detection systems typically are designed for processing single images, whereas the new method processes multiple video frames, providing more robust results. Findings show the Purdue system outperformed two others under development.

The system assigns “confidence levels,” assessing whether the detected cracks are real and provides color-coded confidence levels. The processing procedure takes about a minute.

The researchers have filed a patent application through the Purdue Research Foundation’s Office of Technology Commercialization. The work was supported in part under a contract with the Electric Power Research Institute, an independent, nonprofit energy and environmental research organization.