Building for the Future

Groundbreaking course incorporates interdisciplinary approach to 3D printing for infrastructure

A decade ago, 3D concrete printing was still an emerging technology. It’s now one of the most rapidly growing sectors in the construction industry, projected to reach $40 billion by 2028. A new course offered in the Lyles School of Civil Engineering will equip tomorrow’s engineers with the knowledge and skills necessary to thrive in this new market.

What began as a one-credit class popular with first-year engineering students has now developed into a 400 level course integrated into the curriculum. Beginning this semester, 3D Printing for Infrastructure Applications was offered to engineering and technology students across campus.

“Civil engineering has evolved exponentially in the digital age,” said Pablo Zavattieri, the Jerry M. and Lynda T. Engelhardt Professor in Civil Engineering. “Modern techniques require the use of robots and solving present-day challenges demands out-of-the-box thinking. This course combines design, materials, mechanics, processing and a little bit of chemistry. We’ve taken an interdisciplinary approach to prepare our students to tackle some of the world’s most-pressing needs.”

The course is co-led by Zavattieri; Jan Olek, the James H. and Carol H. Cure Professor in Civil Engineering; Jeffrey Youngblood, professor of materials engineering; Yu Wang, a civil engineering PhD student and Lyles Teaching Fellow; and AlaEddin Douba, a Lillian Gilbreth postdoctoral fellow in civil engineering.

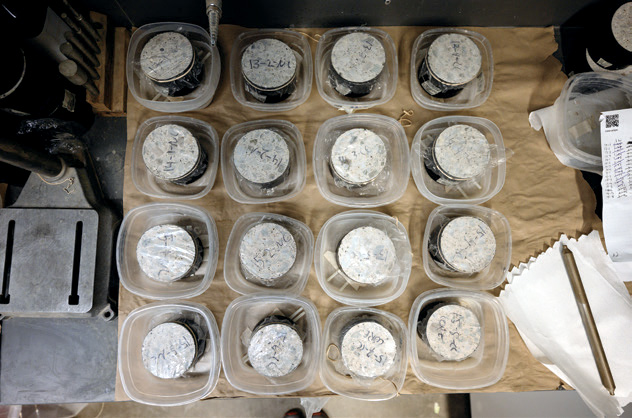

In the course, students work with polymers, metals, cement, mortar and concrete as they design and execute intricate 3D printed models. They will also conduct experiments and develop concrete mixtures to meet the specific requirements and constraints of 3D printing. Guest speakers from industry, national and government labs and other universities visit the course to conduct interactive discussions with the class and present their own projects and case studies that successfully navigated these constraints.

In 3D Printing for Infrastructure Applications, students develop concrete mixtures and work with polymers, metals, cement, mortar and concrete to fabricate structures of their own design.

“We have had speakers from some of the leading construction printing companies in the world, such as COBOD, based in Denmark, and ICON, based in Austin, Texas,” Zavattieri said. “We’ve also invited representatives from RCAM Technologies, a climate tech startup that’s developing 3D printed concrete solutions for offshore renewable energy. These speakers provide real-world insights into engineering design challenges.”

Such challenges include balancing design aesthetics with structural integrity or managing cost-effectiveness while ensuring sustainability. As the students develop their own projects, they are encouraged to showcase their creativity and problem-solving by experimenting with novel materials, structural designs and construction methods.

“Purdue is one of the first universities in the world to offer an undergraduate course on 3D printing for infrastructure,” said Wang, who earned his master’s at Northwestern University. “The persistent pursuit of innovation is ingrained at Purdue. It’s one of the things that motivated me to pursue my PhD studies here. We are leading the nation in 3D concrete printing research. Through this course, we bring together the top minds in the field to pass that knowledge down to our undergraduates.”

Although conventional building methods still have their place, 3D infrastructure printing is quickly becoming the construction technology of the future.

“In this course, students are exploring more than just 3D printing, they’re also studying nature-inspired materials and solutions and imagining how to leverage this technology to establish habitats in outer space,” Zavattieri said. “That’s what makes the interdisciplinary approach so critical. We believe the field of 3D printing for infrastructure will be led by civil engineers, but to design these solutions, we need engineers from other disciplines as well — electrical engineers, data engineers and aerospace engineers, among others.

“Purdue has the faculty expertise, the facilities and the technology to develop future leaders of this industry.”

AlEddin Douba, a Lillian Gilbreth postdoctoral fellow in civil engineering, explains the characteristics of a specific concrete mixture to students in the 3D Printing for Infrastructure Applications course.

Engineering for humanity

The 3D Printing for Infrastructure Applications course aligns with the Lyles School of Civil Engineering’s vision to center engineering for humanity as the cornerstone of the school’s identity.

“Finding solutions to large-scale problems requires civil engineers to focus on societal impact,” Zavattieri said. “We also must expand our discipline by embracing robotic technology and considering space applications. We are not limited. As we look toward the future, we must harness the pioneering technology and expertise available to us to train tomorrow’s civil engineers to create sustainable, resilient and inclusive communities that harmonize with the natural and built environment.”