3D Printing Lab Information

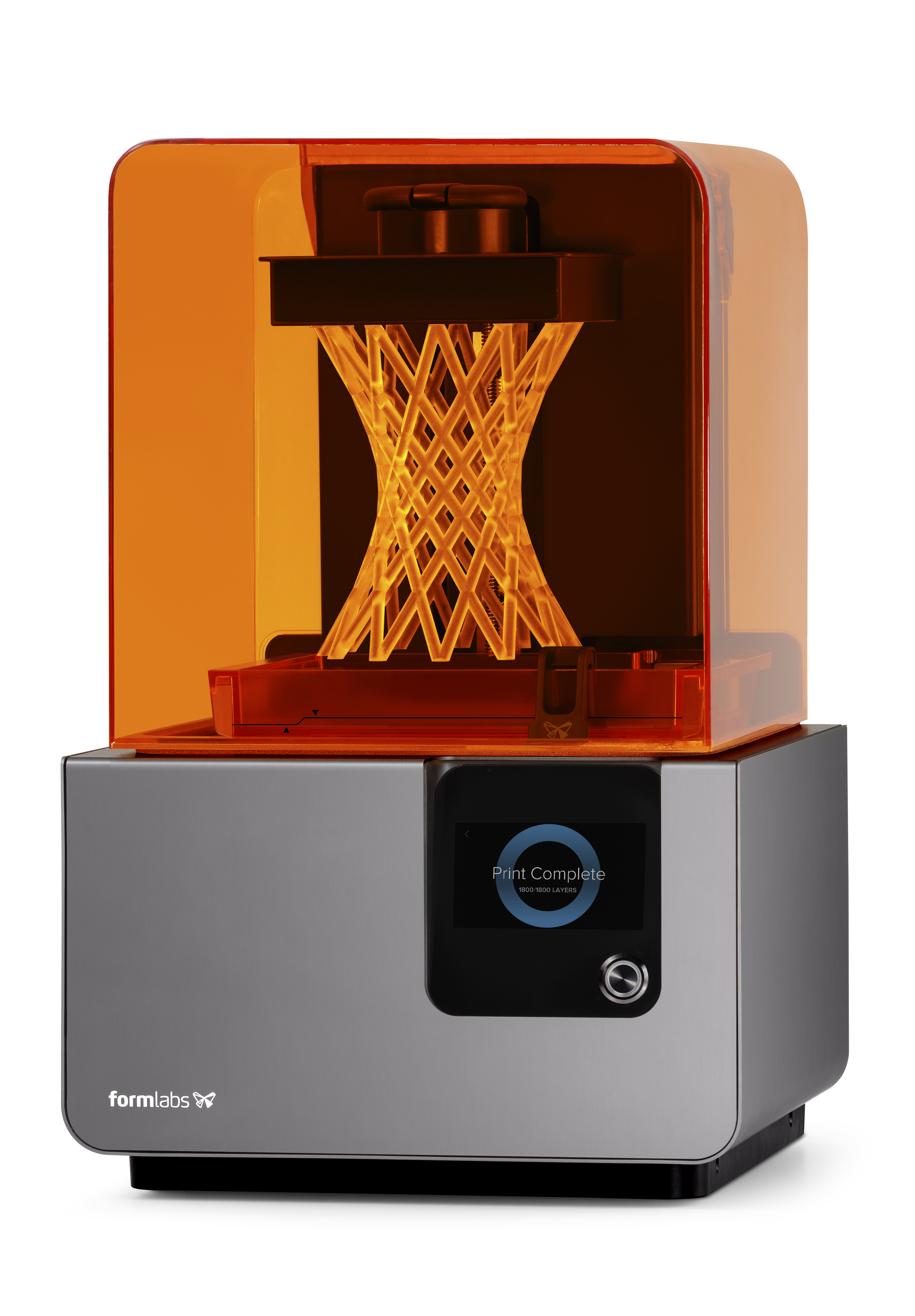

Form-2(2)

Method: Uses a laser to cure liquid resin.

Build Dimensions: 145 X 145 X 175 (mm)

Resolution: 25-100 microns

The Polar 3D Printer(6)

Method: Fused Filament Fabrication (plastic filament)

Build Dimensions: 203 (dia.) X 152 (height), (mm)

Resolution: 100-320 microns

The Printrbot Plus(1)

Method: Fused Filament Fabrication (plastic filament)

Build Dimentions: 254 x 254 x 254 (mm)

Resolution: 100-300 microns

Lab Location

The lab is located in ARMS B098, inside of the Demonstration Studio in the I2I Protyping Studio

Printing Costs

The cost of printing is based upon the amount of material used by weight (includes model resin and support material). Note Form-2 pricing is based on material volume

For 3DPC Members: Unlimited PLA/FDM printing assuming dues have been received.

Non-Member PLA/FDM Printing: $0.10/gram

Form-2: $0.15/mL (member or non member). Please note that resin is significantly more expensive than PLA and other plastics.

No charge if you choose to bring your own material. Please note that 3DPC reserves the right to decide if the provided material is acceptable to be safely used in the desired printer.

Design is an iterative process; you will incur the material costs for all parts printed including those deemed unusable.

Printer Materials

The I2I Lab stocks the following model resins and support material:

PLA Filament, assorted colors

ABS Filament, assorted colors

Form-2 Resin, clear, black, and specialty

Printer Specifications

The specifications for these printers can be found at:

Model Files

The 3D printers require a standard triangulation language (.stl) file format. Most if not all major CAD platforms allow export to STL format. STLs are preferred to be in mm format.

Cleaning Parts

After printing, the parts need to be cleaned to remove the support material. It is expected that you will complete these operations (not 3DPC staff/lab supervisors). The equipment required to do so is provided in the lab.

Printing Time

The printing time is dependent upon the size and complexity of the parts, solid density of the parts, resolution, and the number of objects on the build platform. You will want to allow yourself some time to get the print settings right so you can get a good final product. Do not wait until the day before to print a 24 hour job.

Lab Hours

The lab will be open Monday-Friday, 9 AM-4:30 PM, except on national holidays and breaks. Hours are subject to change with little to no notice due to staffing or other unforeseen issues.

Submitting a Project

The following steps are required to submit a project to the 3D Printer Lab:

- Fill out the Job Submission Form. This lets us know who has a job and when they need it by, as well as get some contact information. You will not be allowed to print your job until you have completed this form

- Fill in the fields at our Dropbox, and attach your files. Please name your files something useful so you will be able to find them when you go to print them in the lab.

- Upload your STL files into the folder, as well as any other CAD models you would like there. Please name them something unique and descriptive. You may view your uploaded fileshere.

- Find some time to come in to the lab. You will want to have some time to get a brief safety introduction to the machine you want to use (if you have never used it before) and some time to get the print started.

- Staff will remove your job from the printer when finished (unless you let them know you would like to do it yourself). Please keep in mind that 3DPC may have to remove the job even if you specify you would like to yourself because the machine might have someone else waiting to print after your job.

About 3DPC

The 3D Printing Club website can be found at purdue3dpc.org This is a good first place to look for extra information. Most questions 3DPC receives can be answered by looking at our website.

Please contact 3DPC via email at: print3d@purdue.edu if you have any questions.