Cool Technology

Incorporation of phase change materials may reduce building's energy consumption

Heating and cooling homes carries a hefty economic and environmental price tag — but Purdue civil engineers are working to change that.

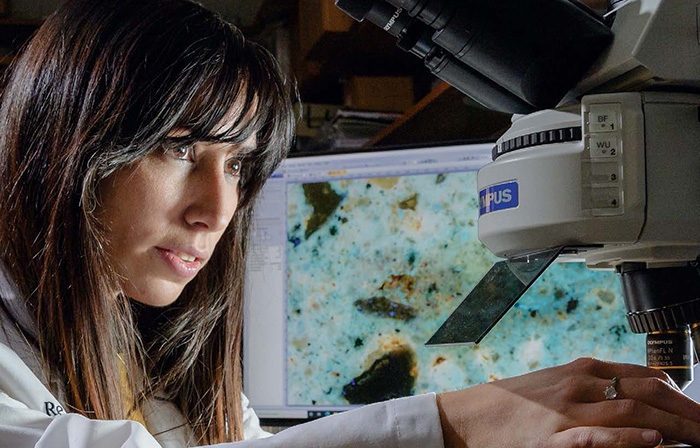

The U.S. Energy Information Administration reported in 2015 that more than half of all home energy in the United States is used for heating and cooling, and it also represents more than 14% of the nation’s overall energy use. To address this issue, Mirian Velay-Lizancos, assistant professor of civil engineering, and her research team have developed a scalable, automatable process that improves upon the traditional method to incorporate phase change materials (PCMs) into construction materials.

A PCM converts changes in thermal energy into phase changes by transitioning from a solid into a liquid, or vice versa. PCMs provide useful cooling or heating by absorbing or releasing energy during those transitions. However, Velay-Lizancos said, PCMs — as they are now — have too many drawbacks to be used in home construction.

“Currently, PCMs are incorporated into other materials via microencapsulation or macroencapsulation,” Velay-Lizancos said. “These methods limit the use of PCMs. Microencapsulation has a negative effect on the strength and durability of construction materials. Macroencapsulation limits the shape and production method of construction materials.”

Velay-Lizancos’ newly-patented method uses liquid immersion and a vacuum to incorporate PCMs after construction materials have already been formed. The method requires only a vacuum system, something Velay-Lizancos said is both easier and more accessible for manufacturers to work with.

“This increases the strength, enhances the durability and increases the thermal inertia of the construction materials,” Velay-Lizancos said. “This new method also distributes PCMs so they are concentrated in the surface layer of the construction materials. More of the PCMs are in contact with external surfaces of the building envelope, which makes the PCMs more effective.”

Marina Garcia Lopez-Arias, a civil engineering PhD student and graduate researcher, said the porous nature of construction materials such as bricks, drywall and concrete make these materials the best choices for incorporating PCMs.

“We’ve observed these types of materials can more easily incorporate PCMs while also not suffering a loss to their integrity,” Lopez-Arias. “They are the ideal materials and what we have focused on.”

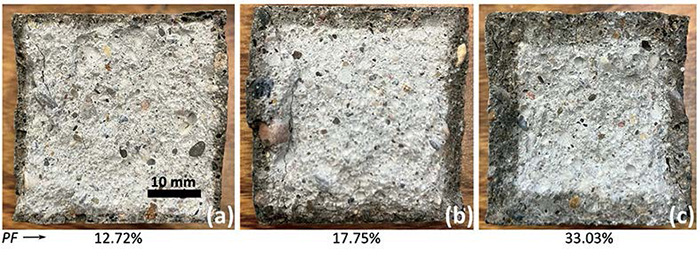

An experimental campaign was conducted on cement mortars with three water-to-cement ratios and, therefore, different initial porosity levels. PCMs were incorporated into the mortars for three different vacuum periods: 15 minutes, one hour and four hours. Velay-Lizancos’ team observed an increase on the thermal inertia of 24% and a more than 22% increase in the compressive strength, with just 7% of the volume of the element filled with PCM.

Velay-Lizancos said the team’s next step is to apply their work to an at-scale setup with cameras and sensors.

“This will allow us to visualize with cameras and sensors the thermal performance of the building envelope,” Velay-Lizancos said. “Clients will have the hard data and also be able to visualize the advantages of this technology.”

Darker areas show how far phase change materials, or PCMs, have penetrated the pores of construction materials that spent 15 minutes, one hour and four hours in a process developed by Mirian Velay-Lizancos, assistant professor of civil engineering, and her research team. The process improves upon the traditional method to incorporate PCMs into construction materials, which could reduce a building’s energy consumption, leading to a reduction in carbon dioxide emissions and operational costs.