Research gains from 3-D printing technology

The advent of 3-D printing has afforded the Lyles School of Civil Engineering a new dimension of data across multiple research areas. Researchers have been finding many beneficial ways to incorporate the tool in applications across a wide range of topics. They include creating 3-D printouts of traffic areas and crash sites, printing objects mimicking an insect shell for structure joints and re-creating soil from Mars.

Making martian soil

Two undergraduate students, Nestor Fabian Rodriguez Buitrago and Oscar Ojeda Ramirez, both natives of Colombia, conducted research on a material simulating Martian soil (referred to as "Martian soil simulator" or Regolith). The two students worked with Ph.D. student M. Reza Moini and civil engineering professors Jan Olek and Pablo Zavattieri as part of a National Science Foundation (NSF) project and the Undergraduate Research Experience Purdue-Colombia (UREP-C) program.

One of the tasks of their research project was to explore the applicability of additive manufacturing (also known a 3-D printing) to create various structural elements from Regolith. If successful, such an approach can potentially lead to the possibility of manufacturing extraterrestrial habitats for future Mars exploration using materials available on the surface of the planet.

"Oscar and Fabian quickly became team players upon joining the team in June 2016 and demonstrated their passion and capabilities in the field of 3-D printing of infrastructure materials," Reza Moini says.

Ojeda Ramirez says it has been an exciting opportunity to collect and study material simulating soil from an alien world in the comfort of an oxygen-rich laboratory. "This has been an amazing experience for me," he says. "This was something I wouldn't have even thought possible until recently, and now we're beginning to study something truly different."

As part of the project, the students have also been evaluating selected mechanical properties of 3-D printed elements with different internal architectures and comparing them to the properties obtained from elements created using conventional (i.e., cast) fabrication methods. That aspect of the study is expected to shed light on how the ability to control the internal architecture of the structure via 3-D printing can enhance the mechanical response of the resulting structural element.

Through 3-D printing, Civil Engineering undergrads Nestor Fabian Rodriguez Buitrago and Oscar Ojeda Ramirez re-created Martian soil for architecture behavior testing.

Re-creating road accidents

Civil Engineering Professor Ayman Habib and Lyles Family Professor of Civil Engineering Darcy Bullock are using 3-D printing and unmanned aerial vehicle imaging to gain a greater understanding of roads and crash sites. Through the use of UAVs and thermal imaging, Bullock and Habib are able to re-create scenes with details and data points that a two-dimensional image cannot provide.

Civil engineering student Brandon Hardin has been assisting Bullock and Habib since August and says the use of newer technologies has been an eye-opening experience.

"The continued addition of 3-D printing to research at Purdue has been very exciting and has given me a completely new perspective on how future research could be conducted," Hardin says. "It just goes to show how adaptable civil engineering has always been and continues to be."

Bullock and Habib take dozens of images collected from the UAV to re-create a near-perfect 3-D printed scale model of a traffic scene. The printed model, they say, gives researchers a reference tool of these recorded events and affords investigators a far greater understanding of potential causes of a crash.

"The details, measurements and distances between objects that we are getting from our UAV are incredible," Bullock says. "This has been especially helpful where, for example, it's night and it's very difficult to survey a crash site. With a UAV's thermal imaging, you're able to clearly re-create the scene and gather data that you simply cannot gain from a flat image."

For now, Habib says, the research team will continue to refine its work and provide greater, tangible results.

"The thermal imaging on the UAV is really something new, and we're still finding ways to utilize it," Habib adds. "We've only been working on this particular study for about a year, but we are excited about the future of this research."

Civil engineering professors Darcy Bullock (left) and Ayman Habib review their latest 3-D printed traffic site. The professors used UAV image data to print a three-dimensional, physical copy.

Insect inspiration

Undergrad Molly Cooper has been working in Professor Pablo Zavattieri's laboratory, exploring naturally occurring joints in nature. More precisely, she studies the puzzle-like connection found in the elytra (the hardened

forewing) of the ironclad beetle, one of the toughest beetles on Earth. This beetle is so tough that an electrical drill is needed to penetrate its shell.

"These are beetles that can be run over by cars and come out alive," Cooper says. "It seemed like a great sample to study and see if we could re-create that strength."

By creating a jigsaw-like pattern, Cooper has been able to create a 3-D printed material that can displace force up to 10 times the amount of an unmodified, similarly sized sample.

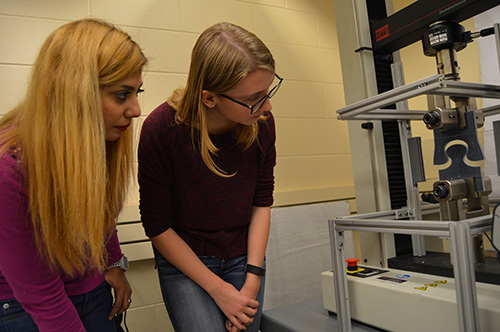

Working with PhD student Maryam Hosseini (left), undergrad Molly Cooper (right) has re-created the jigsaw puzzle-like configuration of the iron-clad beetle via 3-D printing. The printed material is capable of displacing a tremendous amount of energy when under pressure.