In Situ Experiments

In order to validate such modeling approaches and identify fundamental deformation physics, our group conducts in situ micromechanical tests and monitors the strain evolution relative to the microstructural features during loading. This approach allows us to directly compare experiments and models for the same microstructure and at the same length scale. During loading, our group uses a combination of techniques:

-

High energy X-ray diffraction microscopy

-

Synchrotron-based X-ray micro-computed tomography

-

Digital image correlation coupled with electron backscatter diffraction

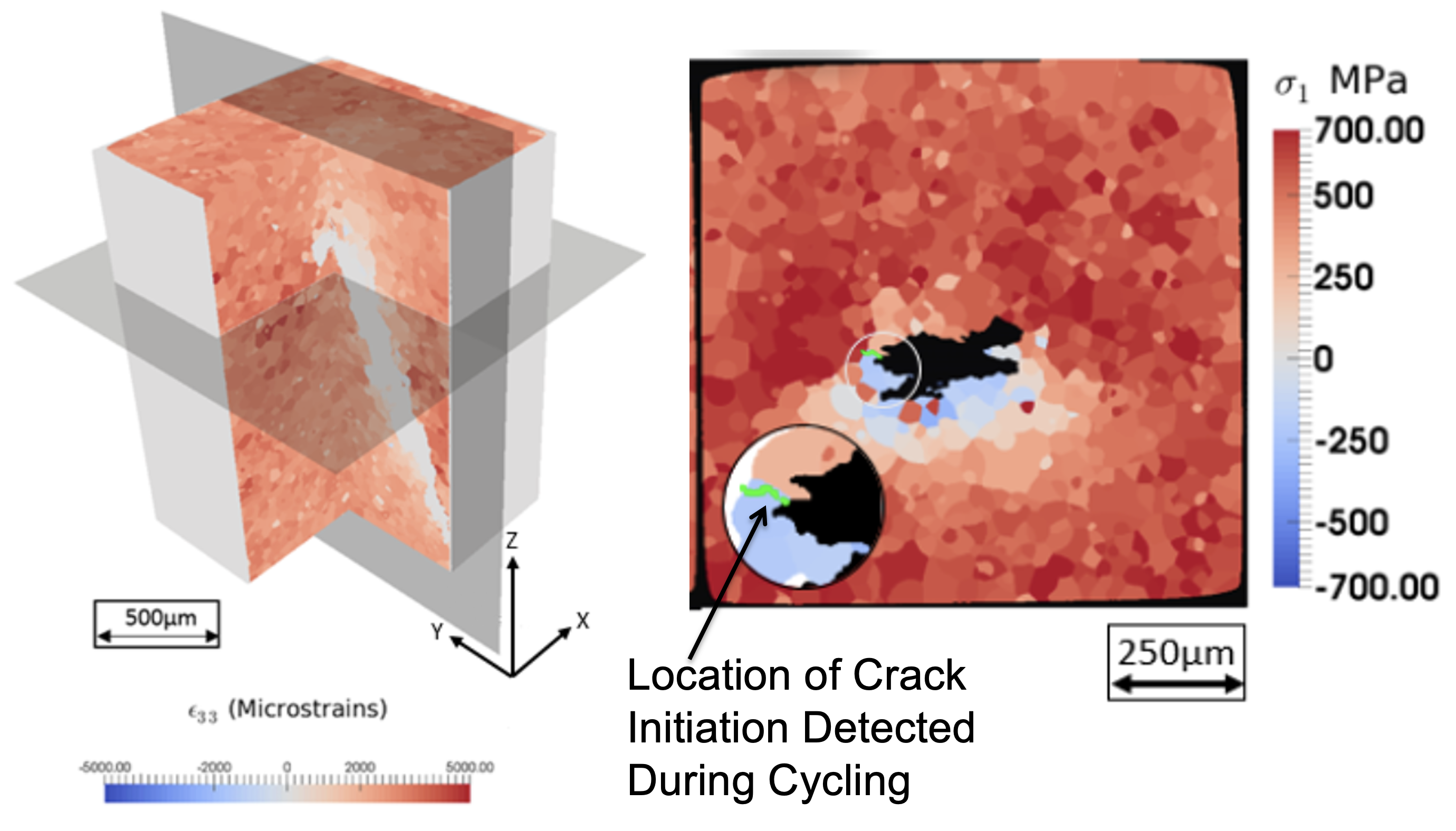

High energy diffraction microscopy (HEDM) experiments are used to measure the evolution of the lattice strains (and thereby the complete stress tensor) in each grain of the polycrystalline material during loading. We can determine the grain morphology (including size, shape, and orientation) and lattice strains of each grain in the volume of interest, thereby simultaneously elucidating information of the microstructure and mechanical behavior of the polycrystalline material, including strain partitioning within the aggregate of grains. Further, the x-ray diffraction capabilities are coupled with tomography to characterize secondary phases (such as non-metallic inclusions) and 3D defects such as cracks or voids during loading. Together, the combined tomography, near-field diffraction, and far-field diffraction experiments provide a detailed understanding for the impetus of failure. An example is shown in the figure below, as crack initiation is observed during in situ loading stemming from debonding and residual stresses around a non-metallic inclusion in the bulk of a specimen. This seminal study monitored the 3D stress states in each grain and their evolution during cyclic loading resulting in the root cause of crack initiation.

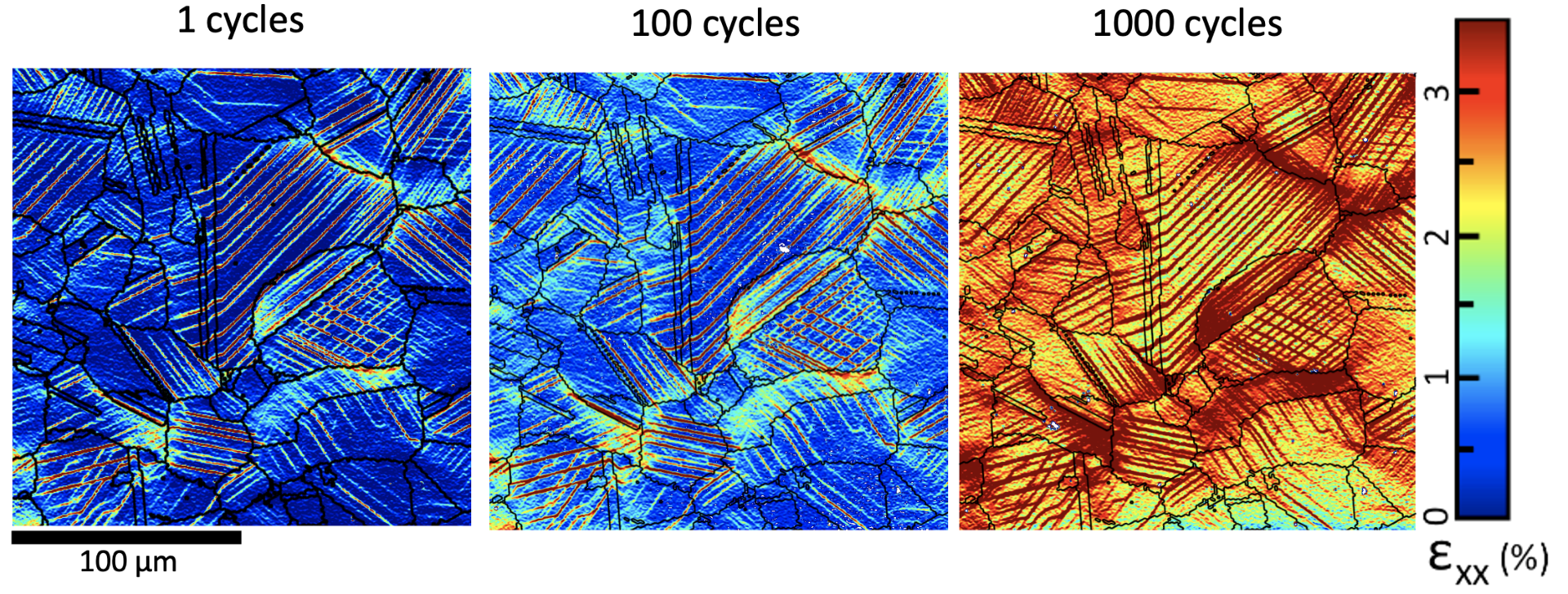

Digital image correlation (DIC) experiments are used to characterize strain heterogeneity at interfaces. For this, a unique experimental set-up is used, which allows concurrent measurements of high-resolution strain heterogeneities at the interface with characterization of the interface structure. This is accomplished by performing in situ deformation experiments by placing the load-frame within a scanning electron microscope (SEM) and using the SEM camera to record digital image correlation measurements of the local spatial displacements. Ultimately, this leads to sub-micron resolution of the strain fields, which can be accompanied with electron backscatter diffraction measurements within the SEM to fully characterize the structure of the interfaces. The figure below shows the evolution of strain maps relative to the materials microstructure during fatigue loading.