Lab and Facilities

The Microstructure Testing and Analysis Laboratory focuses on experimental work on the mechanics of materials with complex microstructures. In the lab there are the following facilities:

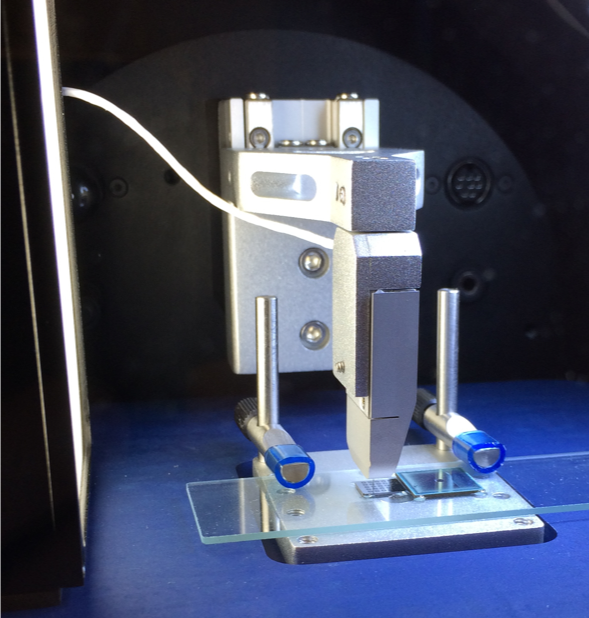

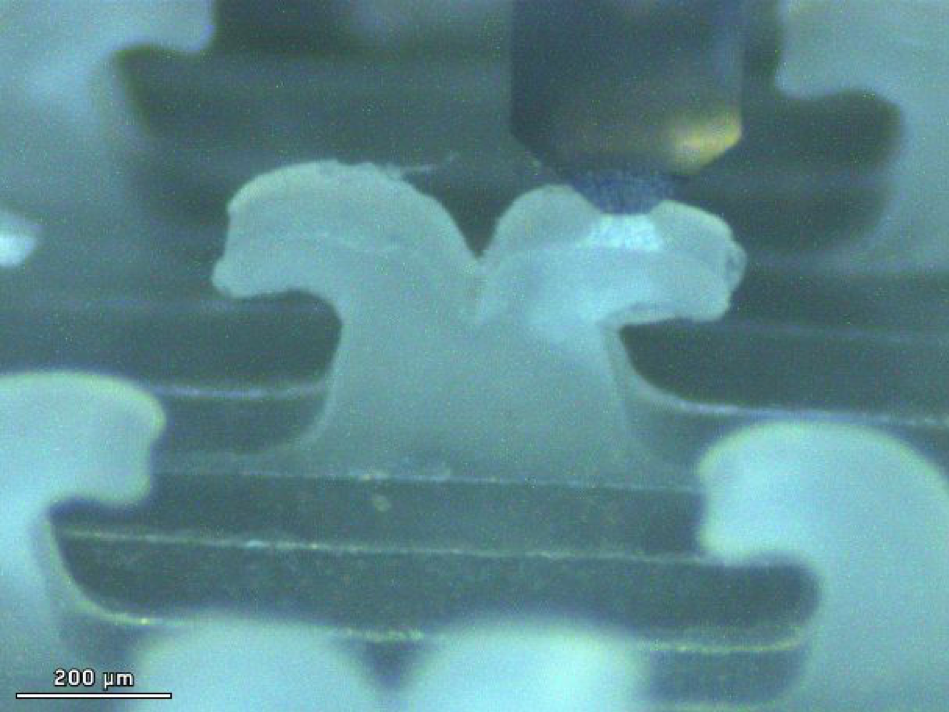

- Micromechanical mechanical test system (FEMTOTOOLS FT-MTA03).

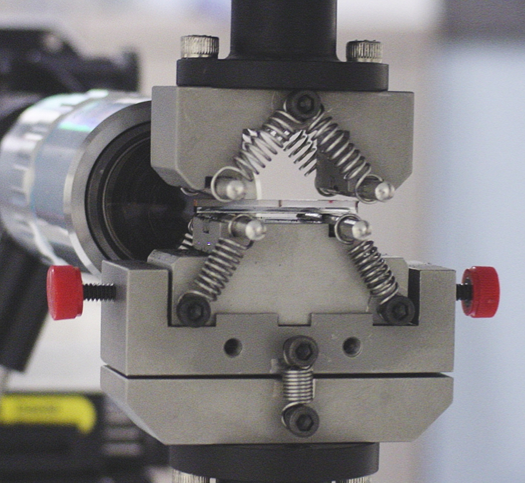

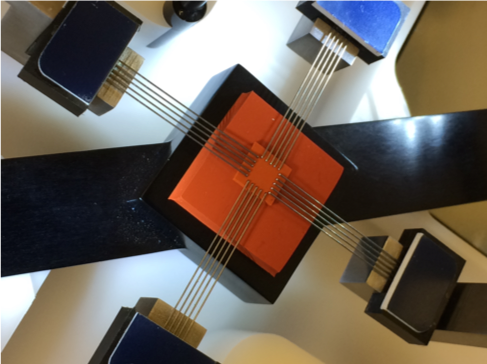

- Small scale, low force material testing (Bose ELF 3200) with a range of load cells and displacement transducers; and axial as well as torsion actuation. This system is pair with long distance microscopes, acoustic emission measurements, and digital image correlation. A range of specimen fixtures are available, and a 4 point bend system is shown below.

- A biaxial material test system (Cellscale BIOTESTER)

- Material manufacturing, including a Connex 350 3D printer, a CAD paper cutter to create special sandwich structures, in-house built reconfigurable molding systems, composite manufacturing by vacuum assisted resin transfer molding, a near net shape short fiber reinforced composite manufacturing system, and a mini milling system.

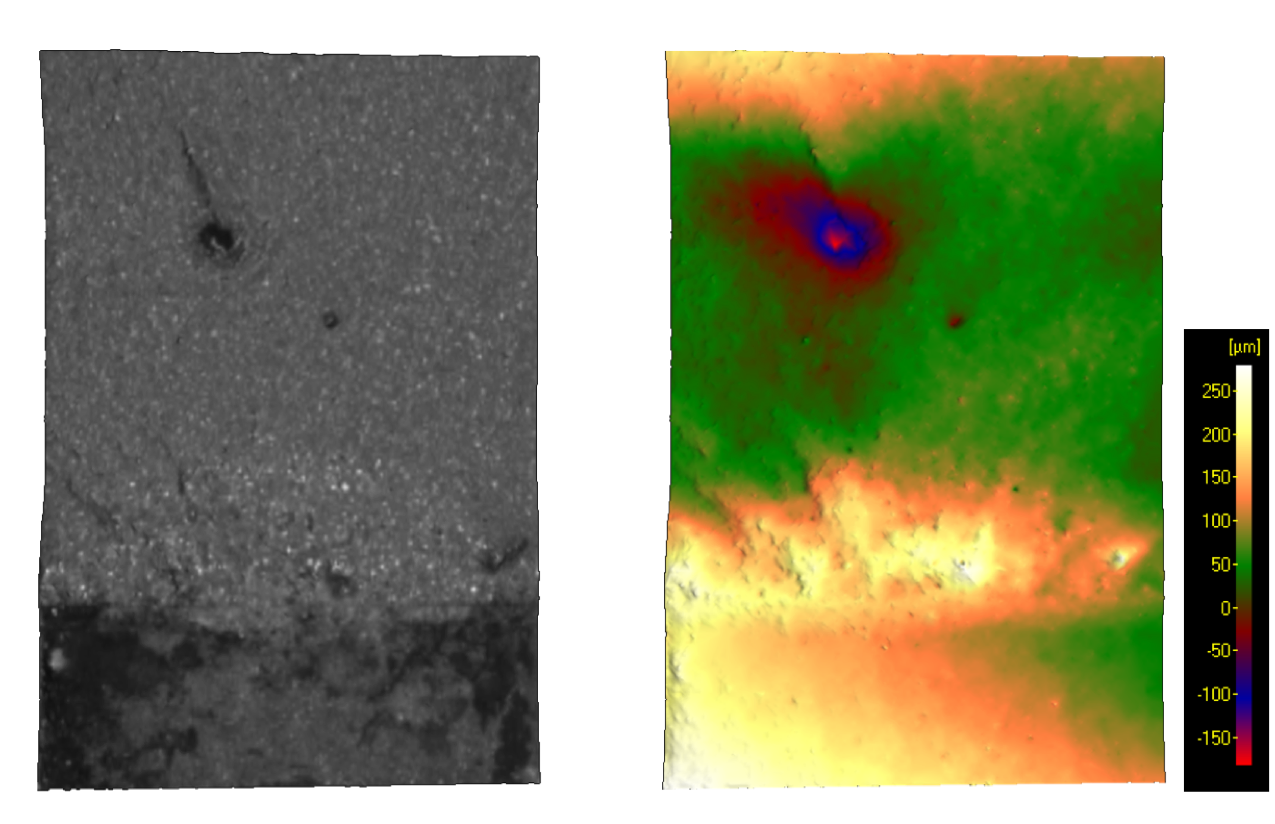

- Microscopy including a Zeiss stereo microscope, a conventional light microscope with a z-index table; and 3D optical stereo-measurement software.

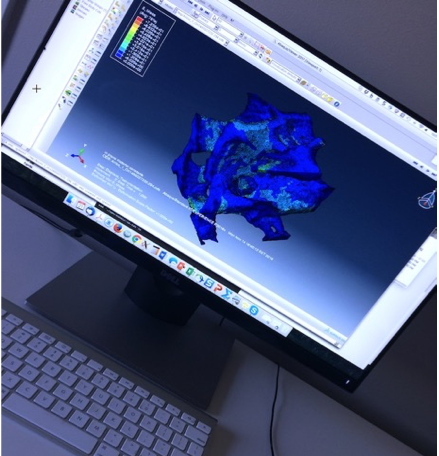

- Several Linux workstations, each with multiple processors as well as GPU capabilities.