Liquid Metal Containing Fiber-Reinforced Composites for Thermal Conductivity Enhancement

Liquid Metal Containing Fiber-Reinforced Composites for Thermal Conductivity Enhancement

| Event Date: | May 16, 2025 |

|---|---|

| Journal: | Applied Composite Materials |

| Paper URL: | Link to Full Text |

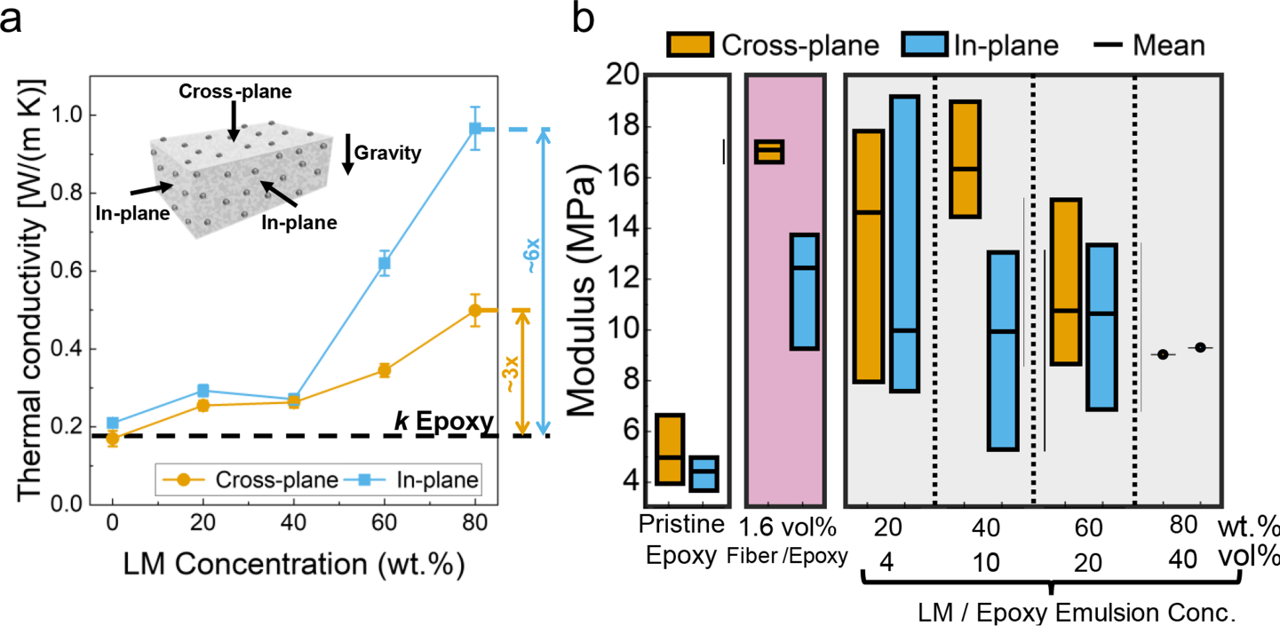

Increasing power density and power consumption in electronic devices necessitate heat-dissipating components with high in-plane and cross-plane thermal conductivity to prevent overheating and enhance performance and reliability. Traditionally, polymer composites are made by incorporating rigid, high thermally conductive fillers within the polymer matrix. However, the filler loadings required to achieve significant thermal conductivity enhancement can impact the mechanical properties of the material system, often making them significantly more rigid or brittle than the base polymer. In this study, we developed a method to incorporate an ultra-high molecular weight polyethylene (UHMWPE) three-dimensional fiber mat and eutectic gallium indium alloy (EGaIn) liquid metal into an epoxy matrix. We integrated in-plane and cross-plane thermal conductivity measurements with flexural modulus assessments to understand the impact of the high thermal conductivity fillers on the thermal and mechanical response of the material. This approach enhances both the in-plane and cross-plane thermal conductivity of the composite, achieving thermal conductivities three times higher in the cross-plane direction and six times higher in the in-plane direction compared to the base polymer. Moreover, mechanical characterization reveals that the mechanical performance of the composite is comparable to that of a fiber-reinforced polymer composite, and the incorporation of liquid metal does not significantly impact stiffness, even at high filler loadings. This work demonstrates the potential of strategic composite design to achieve polymeric materials with optimized thermal-mechanical coupling. These new materials offer a solution to the challenges posed by higher power consumption in electronics, providing improved heat dissipation capabilities for more reliable devices.