Cold sintering to form bulk maghemite for characterization beyond magnetic properties

Cold sintering to form bulk maghemite for characterization beyond magnetic properties

| Event Date: | October 1, 2019 |

|---|---|

| Authors: | Mychal P. Spencer, Wonho Lee, Albraa Alsaati, Corey M. Breznak, Ricardo Braga Nogueira Branco, Jingyao Dai, Enrique D. Gomez, Amy Marconnet, Paris von Lockette, and Namiko Yamamoto |

| Journal: | International Journal of Ceramic Engineering and Science |

| Paper URL: | Full Text |

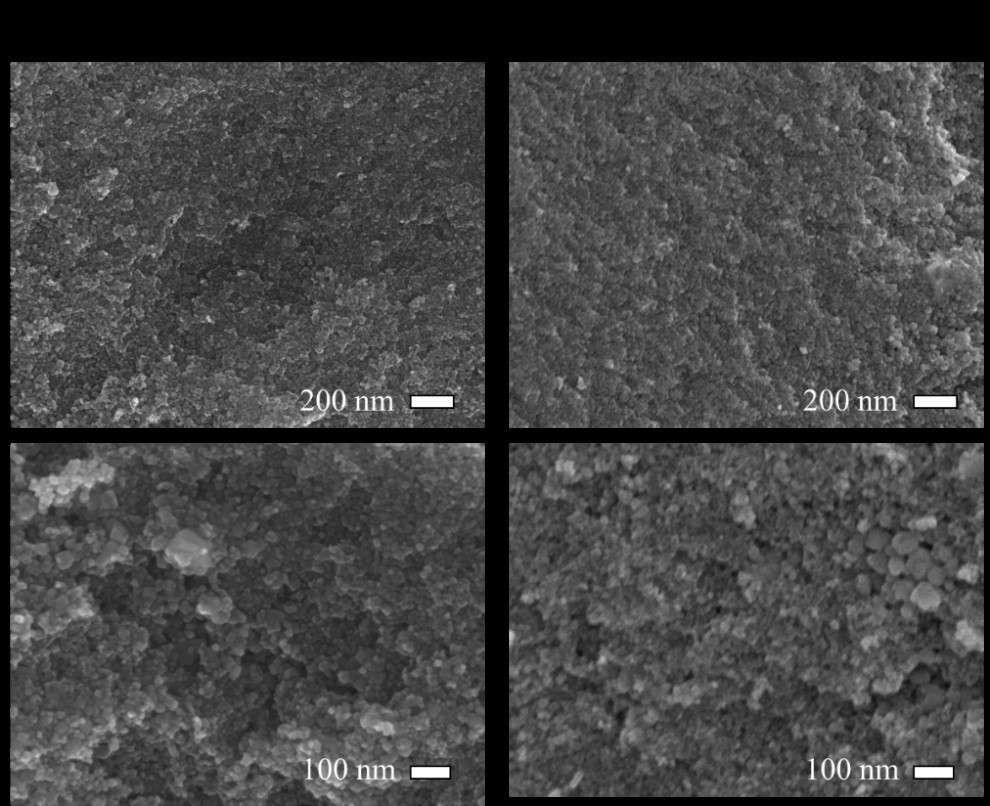

Maghemite nanoparticles have been sought after for electronic, biomedical, and environment applications, for their soft ferrimagnetic properties and large coercivity. While their magnetic properties are well characterized and engineered, their non-magnetic property data are currently not available because maghemite is prepared in nanoparticle forms and their bulk format often has contaminants. In this work, thermodynamically unstable maghemite nanoparticles are cold-sintered (130-250 oC) in water to form bulk samples with submicron-size grains. Their electrical and thermal conductivities were evaluated and presented for the first time: 3.5 10-7 S/m and 0.86-1.30 W/(mK). The relative densities of these cold-sintered samples are low (55.8-64.2%) but comparable or slightly lower with those previously achieved with higher sintering temperature (~55% at 500 oC or ~76% at 1250 oC). Such porous maghemite samples with large surface areas can potentially be used as an anode of lithium-ion batteries, while further densification will be pursued in future by sintering process modification.