| HOME CONTACT

RESEARCH

FACILITIES

PERSONNEL

PUBLICATIONS |

| Achievements

in LAM of Structural Ceramics |

Silicon Nitride

|

Zirconia Ceramics

|

Mullite

|

| Laser-Assisted Machining Research |

| Objectives:

An ultimate objective is to provide a complete physical understanding of the LAM

process (applied to various materials) and the development of a complete thermo-mechanical

model which will enable its commercial application to machine ceramic parts to precise

specifications. Specific objectives of the research include:

- Determine the [LAM] machinability of silicon nitride, zirconia and mullite.

- Find operating conditions which globally optimizes the process, taking into account the

desire to:

- maximize material removal rate

- minimize sub-surface flaws

- minimize surface roughness

- minimize tool wear

- Determine the material removal mechanism for various workpiece materials.

- Determine the tool wear mechanism and tool wear rate for representative LAM conditions.

- Develop material constitutive models for structural ceramics (under investigation) for

stress, strain and strain rates representative of LAM.

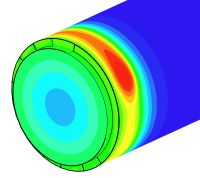

- Develop transient, three-dimensional model of the workpiece undergoing LAM, including

internal radiation for semi-transparent materials.

- Understand the underlying physics of LAM.

- Develop guidelines to determine materials for which LAM is best suited.

- Develop an economic analysis to determine conditions for which LAM is a feasible

alternative to grinding.

Back to Top |

| Research

Plan: The study of laser-assisted machining at Purdue is based on the simultaneous

experimental and numerical investigation of the process. The experiments and modeling

share a symbiotic relationship, as certain parts of one relies on results from the other (Schematic). This allows the underlying physics to be

determined while increasing the machining knowledge-base.

Back to Top |

Numerical Modeling

|

LAM Experiments

|

| SPONSORS National

Science Foundation

Purdue Research Foundation

Cummins Engine Company

Schlumberger

Indiana 21st Century Research and Technology

|

Back to Top |