|

HOME

CONTACT

BACKGROUND

RESEARCH

FACILITIES

PERSONNEL

PUBLICATIONS

|

Laser-assisted machining of hot-pressed silicon nitride is successful. Without laser-assistance, both the workpiece and [cubic-boron nitride] cutting tool fail catastrophically when the cut is initiated. LAM of silicon nitride with a polycrystalline cubic-boron nitride tool can achieve:

Laser-assisted machining of hot-pressed silicon nitride is successful. Without laser-assistance, both the workpiece and [cubic-boron nitride] cutting tool fail catastrophically when the cut is initiated. LAM of silicon nitride with a polycrystalline cubic-boron nitride tool can achieve:

- material removal rates of 16 mm3/s,

- average surface roughness as low as 0.3 microns,

- tool life in excess of 40 minutes, and

- no evidence of sub-surface damage.

The part pictured above was turned down to a smallest diameter of 1.70 mm, from an 8 mm diameter blank, in three passes. The workpiece was mounted in a 4-jaw chuck (without any free-end support) with an extended (from the chuck) length of 35 mm.

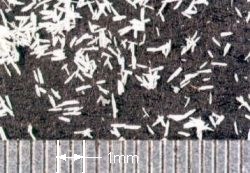

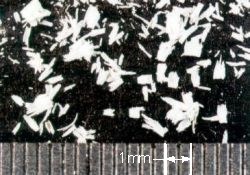

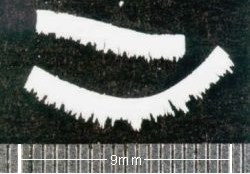

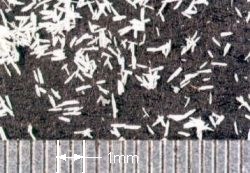

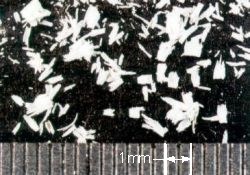

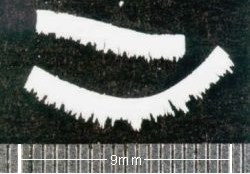

Laser-assisted machining uses a laser to heat the workpiece in the vicinity of the material removal location. At elevated temperatures the yield strength of some brittle materials decreases below the fracture strength, changing the material deformation behavior from brittle to ductile, thereby enabling a "standard" cutting tool to remove material. The following chips produced during LAM of hot-pressed silicon nitride show evidence of plastic deformation during the cutting process.

- Fragmented chips; Material Removal Temperature (Tmr) < 1150C*

- Short semi-continuous chips; 1150C < Tmr < 1300C*

- Long semi-continuous chips; Tmr > 1300C*

* The uncertainty in the published material removal temperatures is +/- 50C.

Back to Top

|

Laser-assisted machining of hot-pressed silicon nitride is successful. Without laser-assistance, both the workpiece and [cubic-boron nitride] cutting tool fail catastrophically when the cut is initiated. LAM of silicon nitride with a polycrystalline cubic-boron nitride tool can achieve:

Laser-assisted machining of hot-pressed silicon nitride is successful. Without laser-assistance, both the workpiece and [cubic-boron nitride] cutting tool fail catastrophically when the cut is initiated. LAM of silicon nitride with a polycrystalline cubic-boron nitride tool can achieve: