| HOME CONTACT

RESEARCH

FACILITIES

PERSONNEL

PUBLICATIONS |

|

Achievements in Laser Cladding |

|

Stellite Cladding Example

|

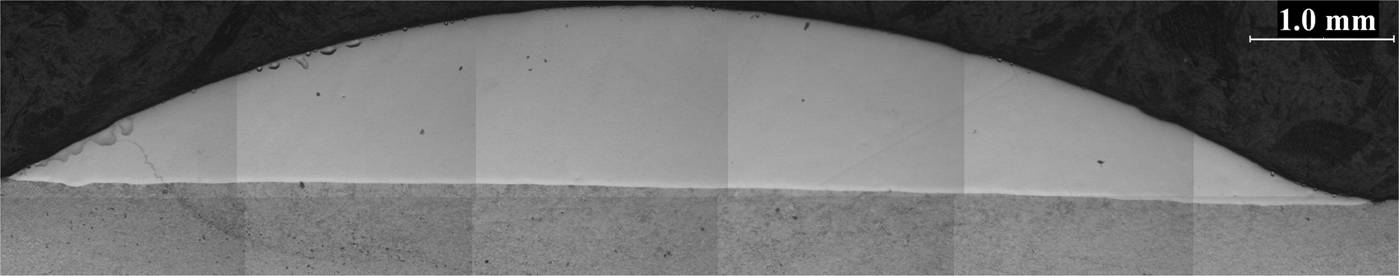

Micrograph of the cross section of a clad sample  |

| Laser

Cladding Research |

| Objectives:

The goal of this project area is to provide a complete physical understanding of the laser

cladding process (applied to various materials) and the development of a complete

predictive

model that will enable optimization of the process and its commercial application to

cladding

of various engineering surfaces

to meet precise specifications. Specific objectives of the research include:

- Find operating conditions that globally optimize the process in

order to:

- maximize laser cladding rate

- minimize sub-surface flaws

- maximize clad zone quality

- Investigate the laser cladding mechanism for various materials.

- Develop a predictive transient, three-dimensional thermo-diffusion model for laser

cladding.

- Understand the underlying physics of laser cladding.

- Develop guidelines to determine materials for which laser cladding is best suited.

- Develop an economic analysis of laser cladding against current practice

Back to Top |

| Research

Plan: The study of laser-cladding at Purdue is based on the simultaneous

experimental and numerical investigation of the process. The experiments

are conducted using three different state-of-the-art set-ups, providing

an array of different capabilities. The existing set-ups

provide the capabilities of cladding a surface with a complex contour

using a high power direct diode laser (HPDL) due to the seven d.o.f. positioning ability and harmonizing software. Modeling

efforts include prediction of powder flow, melting and solidification,

resultant microstructure, deposited layer dimension and resultant

residual stresses. Several models are integrated to provide

the comprehensive predictive capabilities.

Back to Top

|

| Research

Progress:

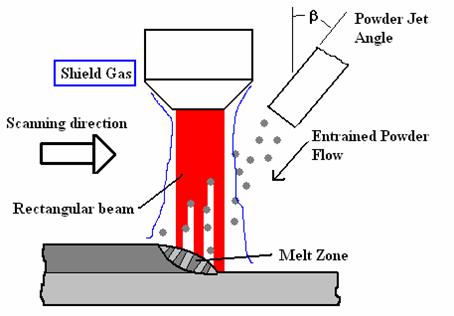

- Successful laser cladding of various materials has

been achieved by preplaced cladding and blown power cladding (see

the figures above for Stellite 6 on 1018 steel alloy ).

Deposited tracks no porosity, no cracks and minimal dilution (2-3%).

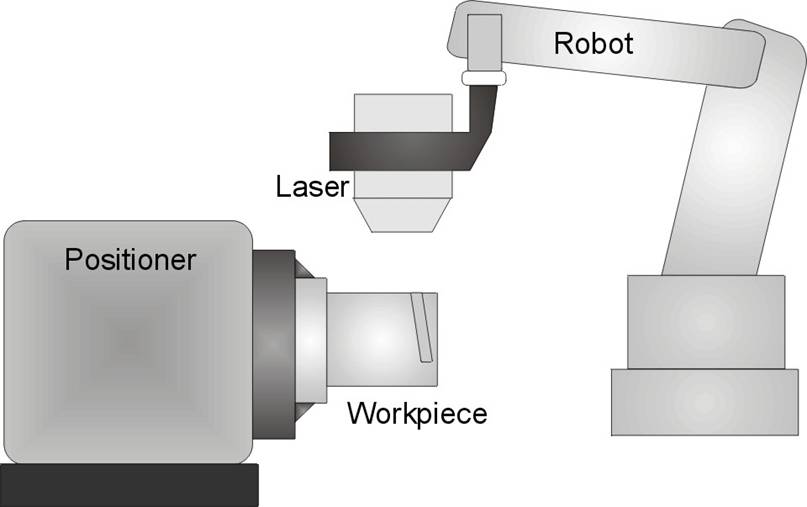

- A flexible cladding set-up (seven d.o.f.) has been established (see the

right figure below).

- Current work includes blown powder cladding, and preplaced

cladding of different materials.

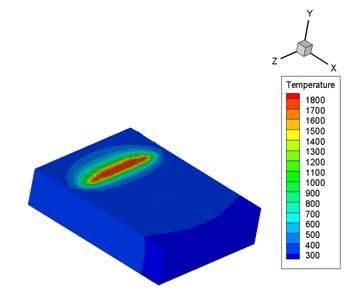

- A predictive numerical model has been developed to predict and

optimize operating conditions during the cladding (see figures blow)

- Experimental measurements of powder velocities and temperature

during blown powder cladding have been performed to verify the

predictive model.

Back to Top |

| Schematic of blown powder cladding

|

Cladding Experimental Set-up

|

Predicted molten pool |

Predicted clad geometry |

| SPONSORS National

Science Foundation

Purdue Research Foundation

Indiana 21st Century Research and Technology

Caterpillar

Adiabatics

|

Back to Top |