| HOME CONTACT

RESEARCH

FACILITIES

PERSONNEL

PUBLICATION IN AM

ALL PUBLICATIONS |

| Laser

Additive Manufacturing Research |

| Objectives:

The goal of this project area is to develop the critical and enhanced capabilities of

building three dimensional functional parts directly from CAD drawings

and synthesizing novel materials using various laser-based additive

manufacturing processes. It also aims at developing a complete

set of predictive

models that will facilitate design, optimization, qualifications of the

AM processes and their commercial applications. Specific objectives of the research include:

- Find optimal operating conditions for various applications in

order to:

- maximize build rate

- minimize sub-surface flaws

- maximize part quality

- Develop functionally grade deposition capabilities of material for various materials.

- Develop a comprehensive set of predictive multi-physics models

that link process-microstructure-mechanical properties for laser-based

additive manufacturing processes.

- Develop data-driven models that will capture the physical

relationships

- Develop the capabilities of synthesizing metal matrix composites

- Develop the in-situ synthesis of novel materials such as bulk metallic glass materials,

shape memory alloys and high entropy alloys

- Develop in-process monitoring and control schemes for the laser

additive manufacturing processes.

Back to Top |

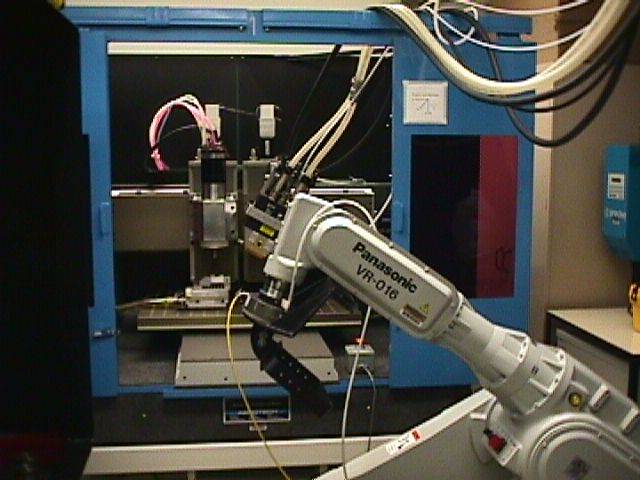

| Research

Plan: The study of laser additive manufacturing at Purdue is based on

the simultaneous experimental and numerical investigation of various AM processes. The experimental investigations are carried out using

multiple additive manufacturing systems (both blown powder and powderbed, see the bottom figures) to develop various applications including direct

fabrication of functional parts, in-situ synthesis of metal matrix

composites and new alloys, and functionally graded materials. Modeling

efforts include multi-physics based comprehensive predictive models

for prediction of powder flow, melting and solidification,

resultant microstructure, deposited layer dimension and resultant

residual stresses. To this end, various in-house developed

codes have been developed

and are coupled with commercial FEM codes such as Abaqus to calculate the

resultant residual stresses and mechanical properties. A number of

parallel processing computing workstations in cluster are available and

being used for these computational work.

Back to Top

|

| Research

Progress:

- Experimental studies on AM of over 30 different materials,

including following materials:

|

Iron and steels |

|

Fe, H13, SS316, SS304, ODS steel |

|

Other Alloys |

|

Ti-based: CP Ti, Ti6Al4V |

|

Ni-based: Inconel 625, Inconel 690,

Inconel 718 |

|

Al-based: Al4047, Al6061, Al7075 |

|

NiTi shape memory alloy |

|

Bulk metallic glasses (FebalCr25Mo20W10Mn5C3Si2B5,

Zr65Al10Ni10Cu15) |

|

Co-Cr-based: Stellite 6 (Co-Cr-W-C+others),

Co-Cr-Mo |

|

Monel K500 (Ni63Co27-33+others) |

|

Metal matrix composites |

|

Ti-TiC |

|

Al-SiC |

|

Ti6Al4V-TiC |

|

In690-TiC |

|

Other materials |

|

W, Mo, Graphite, ZrO2 |

- A comprehensive set of physics-based models:

- Process models:

- modeling for powder flow distribution and temperature from the co-axial nozzle,

- comprehensive molten pool model considering free surface

tracking, coupled with the powder distribution model has been developed to optimize operating conditions

of the directed energy deposition processes (see Figs. 1 and 2

below)

- high fidelity powderbed fusion process model,

considering powder spread, powder dynamics, molten pool

dynamics considering denudation and powder-molten material

interaction, etc.

- Microstructure prediction models:

- phase field modeling for solidification (2D, 3D)

- cellular-automata model for large domain grain

morphology prediction (3D)

- hybrid cellular automat-phase field model that improves

the computational efficiency by 4 orders of magnitude over

phase field model (2D, 3D)

- solid state phase transformation models

- Mechanics model

- prediction of mechanical properties based on

microstructure (multiscale models)

- prediction of mechanical properties based on

microstructure (structural genome based)

- metallo-thermo-mechanical modeling for prediction of

residual stresses

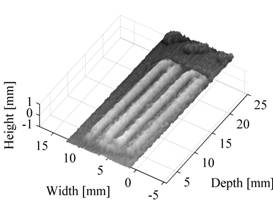

- In-process monitoring

- An on-line track monitoring system based on a vision system and

a scanning laser has been developed. This system is

capable of measuring the three dimensional deposited tracks in real

time (see Figs.

3 and 4 below).

- In-process molten pool monitoring

- In-process porosity monitoring

- Applications:

- Successful fabrication of various parts including hip implants

(see the sample parts on the top of this page).

- Functional gradient coating

- Synthesis of bulk metallic glasses

- Synthesis of Nitinol with controlled phase transformation

temperature and mechanical properties

- Remanufacturing of legacy parts

- Synthesis of magnetic materials

- Synthesis of nuclear reactor materials

- In-situ synthesis of metal matrix composites

|

Fig. 1: Molten pool and deposition

track model |

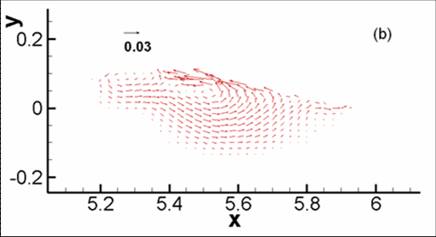

Fig. 2: Molten pool fluid flow prediction |

|

Fig. 3: Actual track |

Fig. 4: Measured

Track by the vision system |

Back to Top

|

Fig.

5: 5 axis direct deposition system

|

Fig. 6:

Optomec LENS 750 |

|

SPONSORS National

Science Foundation, DoD, DoE, DTRA, NASA

Purdue Research Foundation

Indiana 21st Century Research and Technology Fund

Industrial Companies

|

Back to Top |