| Laser

Peening Research |

| Objectives:

The goal of this project area is to provide a complete physical understanding of the laser

peening process and to develop a comprehensive

predictive

model, which will enable optimization of the process to achieve desired

residual stress specifications. Specific objectives of the research include:

- Study the fundamentals of laser-material-plasma interaction during

laser peening processes.

- Develop comprehensive predictive modeling capability for laser

peening processes.

- Find operating conditions that globally optimize the process in

order to:

- maximize laser peening rate

- achieve desired residual stress distributions.

- Study the laser peening mechanism for various workpiece materials.

- Develop guidelines to determine materials for which laser peening is best suited.

- Develop an economic analysis of laser peening against current practice.

Back to Top |

Research

Plan:

The study of laser

shock peening at Purdue is based on the simultaneous

experimental and numerical investigation of the process. The experiments

are performed using a ns solid state laser integrated with a positioning

system. Modeling

efforts aim at developing a comprehensive predictive model, which allows

the prediction of residual stress profiles in terms of laser operating

parameters, coating material and thickness, and workpiece material,

while accounting for the existing stress distribution. This allows the underlying physics to be determined while increasing the

laser shock peening

knowledge-base.

|

| Research

Progress:

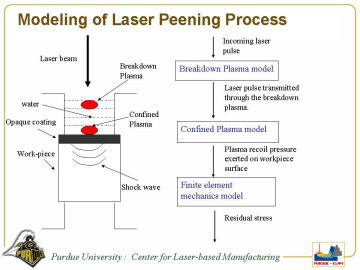

- A comprehensive 1D thermal model of laser peening process has been

developed. The model is capable of predicting plasma

pressure, laser-plasma interaction, electron densities, etc. (figures in the

top row below)

- The water breakdown plasma phenomenon has been successfully

modeled. This can provide the limit of laser peening

processes in terms of laser power.

- A 3D finite element modeling procedure of predicting residual stresses with

given plasma recoil pressure has been developed. This can

provide the resultant residual stress distributions (figure in bottom

row below)

- Laser-based monitoring techniques are being developed to monitor

various conditions such as plasma plume size, plasma temperature and

electron density during laser shock peening processes.

Back to Top |

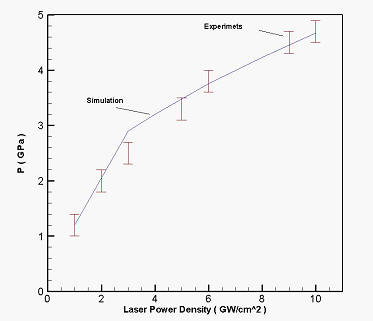

| Predicted Plasma Pressure

vs. Time  |

Predicted

vs. Measured Max. Plasma Pressure

|

|

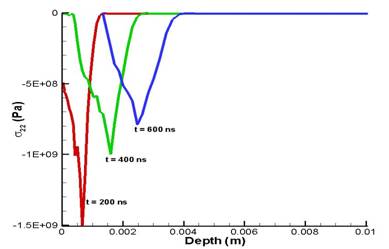

| FEA predicted

shock wave propagation in A356-T6 alloy workpiece

|

Predicted

vs. Measured Residual Stress Distribution

|

|

| SPONSORS National

Science Foundation

Purdue Research Foundation

Indiana 21st Century Research and Technology

Industrial partners

|