| HOME CONTACT

RESEARCH

FACILITIES

PERSONNEL

PUBLICATIONS |

|

Laser Welding Processes Under Research |

|

Conduction welding |

Key hole welding |

Laser-assisted FSW |

| Laser

Welding Research |

| Objectives:

The goal of this project area is to develop novel laser welding

applications at both macro and micro scales, using solid state lasers along with comprehensive modeling,

monitoring

and control capabilities. The developed predictive models consist of

a weld pool

model for key-hole dynamics, a solidification model, and a diffusion kinetics model,

which can predict the resultant microstructure and mechanical properties

of the weld joint. More specific goals include:

- Find optimal operating conditions for different materials in

order to:

- maximize laser welding rate

- minimize sub-surface flaws

- maximize weld joint quality

- Develop novel applications of laser welding such as fuel cell

stacks, magnesium alloys, zinc-coated steels, aluminum panels and

dissimilar materials

- Develop a comprehensive predictive multi-physics model for laser

welding processes.

- Develop in-process monitoring and control schemes for the laser

welding process.

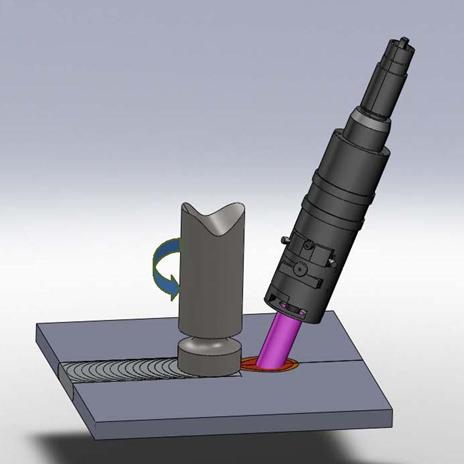

- Develop a laser-assisted friction stir welding process for

difficult-to-weld materials

Back to Top |

| Research

Plan: The study of laser welding Purdue is based on the simultaneous

experimental and numerical investigation of the process. The experimental

investigations

are being carried out using the high power fiber

laser set-up integrated with three axis machining center and diagnostics

capabilities for the entire welding process.

Modeling

efforts include development of multi-physics models for prediction of laser beam absorption, plasma-laser

interaction, melting and solidification, resultant microstructure, weld

pool dimension and resultant

residual stresses. Several

parallel processing computing workstations in cluster are available and

being used for these computational work.

Back to Top

|

| Research

Progress:

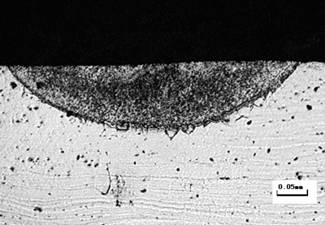

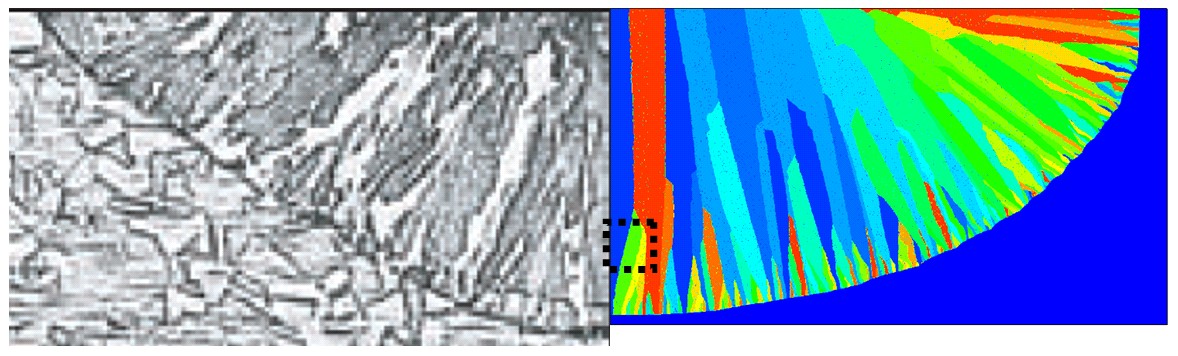

- A predictive microstructure evolution model

has been developed based on the combined Cellular Automata and

Phase Field method (see the sample result in Fig. 1).

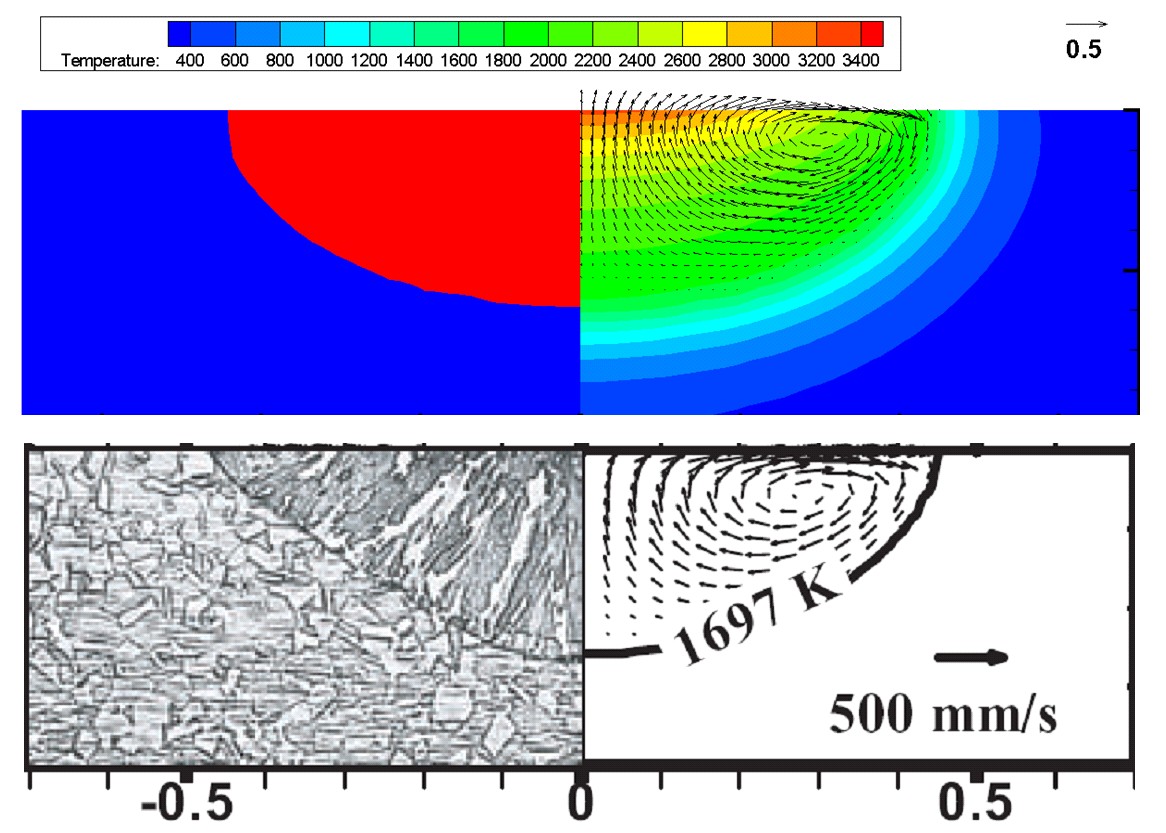

- A comprehensive molten pool model considering free surface

tracking has been developed for both fusion welding and keyhole

welding and is being coupled with the microstructure evolution model

(see Fig. 2 and 3).

- An experimental system has been established (Fig. 4).

- An on-line weld pool monitoring and control system has been

developed and successfully demonstrated.

|

Fig. 1: Predicted and measured

columnar dendrite after fusion welding

|

Fig. 2: Predicted and measured molten

pools during fusion welding

|

|

Fig. 3: Predicted

and measured keyhole weld pool

|

Fig.

4: Laser welding system |

Back to Top

|

| SPONSORS National

Science Foundation

Industrial Members

|

Back to Top |