| HOME

CONTACT

BACKGROUND

RESEARCH

FACILITIES

PERSONNEL

PUBLICATION IN LAM

PUBLICATIONS |

| Laser-Assisted Machining Research |

| Objectives:

An ultimate objective is to provide alternative, economically

attractive machining process capabilities with a complete physical understanding of the LAM

processes and the development of a comprehensive thermo-mechanical

model that will enable its commercial application to machine parts made

of advanced materials such as ceramics, composites and high temperature

alloys to precise

specifications. Specific objectives of the research include:

- Determine the [LAM] machinability improvement of ceramics

including silicon nitride, zirconia and mullite, various metal

matrix composites and high temperature alloys including titanium

alloys, nickel-based alloys and hardened alloys.

- Find operating conditions that globally optimize the processes, taking into account to:

- maximize material removal rate

- minimize sub-surface flaws

- minimize surface roughness

- minimize tool wear

- Determine the material removal mechanisms for various workpiece materials.

- Determine the tool wear mechanism and tool wear rate for representative LAM conditions.

- Develop material constitutive models for various materials for

stress, strain and strain rates representative of LAM.

- Develop transient, three-dimensional model of the workpiece undergoing LAM, including

internal radiation for semi-transparent materials.

- Understand the underlying physics of LAM.

- Develop guidelines to determine materials for which LAM is best suited.

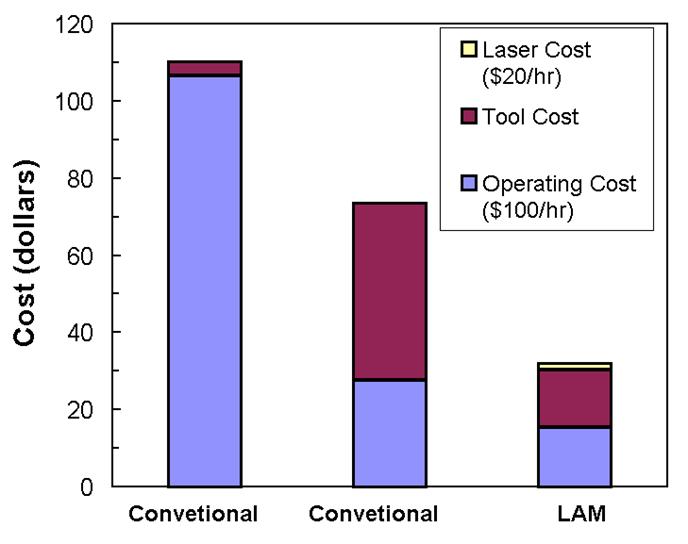

- Develop an economic analysis to determine conditions for which LAM is a feasible

alternative to grinding or hard turning.

Back to Top |

| Research

Plan: The study of laser-assisted machining at Purdue is based on the simultaneous

experimental and numerical investigation of various processes including

turning, milling and micromilling. The experiments and modeling

share a symbiotic relationship, as certain parts of one relies on results from the other (Schematic). This allows the underlying physics to be

determined while increasing the machining knowledge-base.

Back to Top

|

Achievements

in LAM

| |

|

Experimental results:

-

LAM has been

successfully applied to machining of various ceramics such as

silicon nitride, partially stabilized zirconia and mullite (as shown

below). A significant improvement of machinability has been

achieved with long tool life up to 2 hours.

-

LAM has been

successful in improving machinability of various

difficult-to-machine alloys such as Inconel 718, Ti-6Al-4V, Waspaloy,

Compacted Graphite Iron, stainless steel (P550), hardened steel,

high Cr. steel, and metal matrix composites. Typical improvement

includes 30% reduction in specific cutting energy, 2-4 fold

improvement in surface roughness, and 2-4 fold improvement of tool

life. It has been demonstrated that LAM does not

adversely affect the subsurface integrity (no microstructural

changes, no subsurface damage or cracks, compressive residual

stresses).

-

LAM capabilities for

micromachining have been successfully demonstrated for various

materials, including titanium alloys, ceramics and ceramic-matrix

composites. In each case, a significant improvement of

tool life, surface quality and cost savings has been demonstrated.

Modeling results:

-

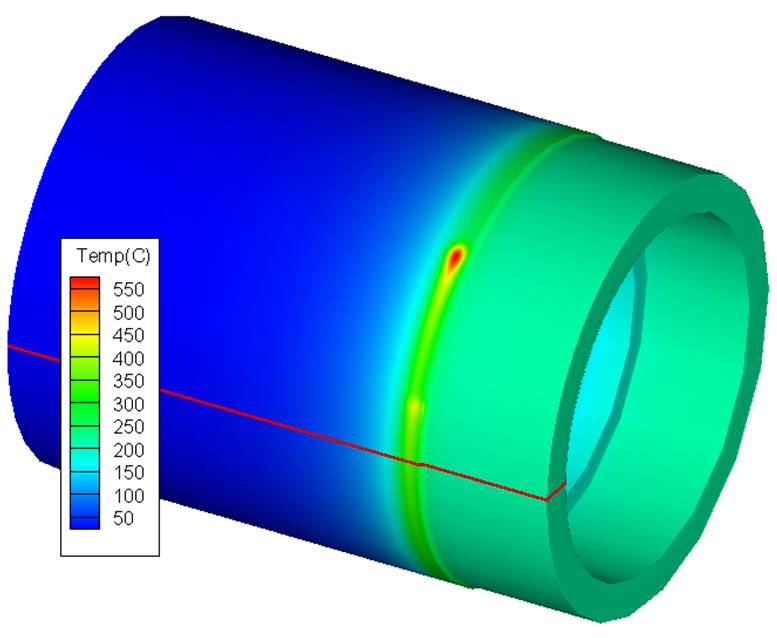

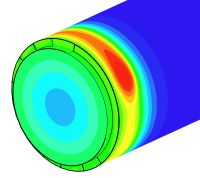

Three-dimensional

transient numerical models have been developed to predict the

workpiece temperature distributions during laser-assisted turning and milling

operations.

-

Multi-scale,

multi-phase finite element models have been developed to predict the

LAM processes and subsurface damage.

|

Silicon Nitride

|

Zirconia Ceramics

|

Mullite

|

|

Thermal

Model

|

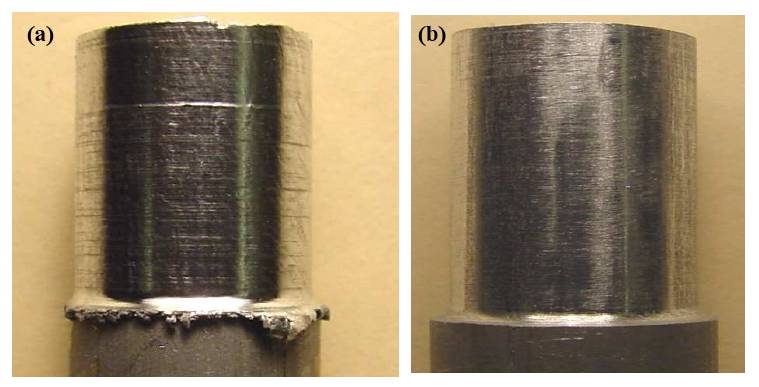

Comparison between conventional machining and LAM of MMC

Conventional

LAM |

Economic

Analysis

|

Back to Top |

Numerical Modeling

|

LAM Experiments

|

| SPONSORS National

Science Foundation

Caterpillar,

Schlumberger, Lockheed Martin, Weir Minerals, Rolls Royce, Boeing, GE

Aviation

Indiana 21st Century Research and Technology

DoD, NASA

|

Back to Top |