| HOME CONTACT

RESEARCH

FACILITIES

PERSONNEL

PUBLICATIONS |

|

Concept of Laser Hardening |

|

Thermal Model

predicted vs. experiment

|

Temperature Gradient

|

Hardened Surface

|

| Laser

Hardening Research |

| Objectives:

The goal of this project area is to provide a complete physical understanding of the laser

hardening process (applied to various materials) and to develop accurate

predictive

models that will enable optimization of the process and its industrial applications to various engineering

materials

to meet precise specifications. Specific objectives of the research include:

- Find operating conditions that globally optimize laser hardening processes in

order to:

- maximize laser hardening rate

- minimize sub-surface flaws

- maximize surface hardness and case depth

- Investigate the underlying laser hardening mechanisms for various work materials

and geometries.

- Develop a predictive transient, three-dimensional thermo-kinetic-stress model for laser hardening.

- Develop guidelines to determine the best way of performing laser hardening

for various materials and geometries.

- Develop an economic analysis of laser hardening against current practice

|

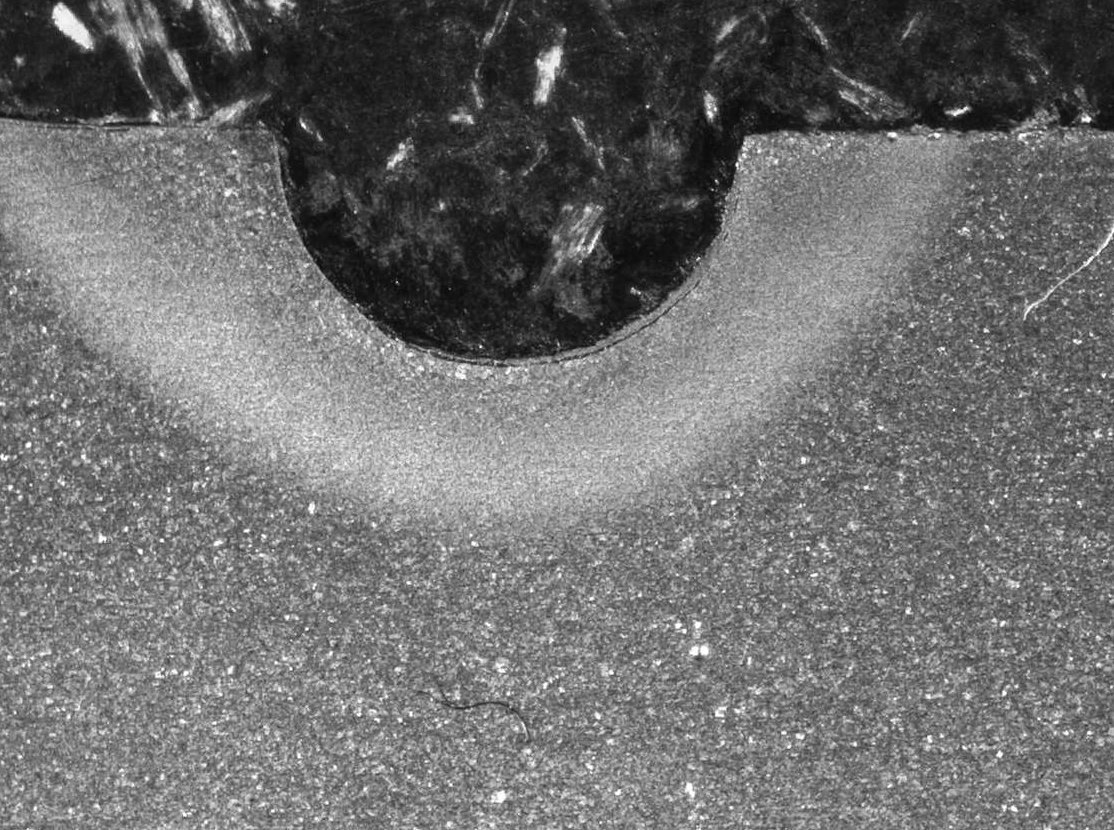

| Research

Plan: The study of laser-hardening at Purdue is based on the simultaneous

experimental and numerical investigation of the process. The experiments

are performed on an integrated processing cell comprising a 4 kW direct diode laser with a rectangular beam

shape and an 7axis positioning system (bottom right Figure) as well as a CO2 and a Nd:YAG laser providing circular beams. Modeling

efforts include three-dimensional heat transfer modeling, kinetic

modeling of diffusion kinetics, deformation and stress modeling.

These models are coupled together to provide comprehensive hardening

results including hardness profiles, deformation and resultant residual

stresses.

|

| Research

Progress:

- Successful laser hardening of 5150H, 4140 and 1045 steel alloys

has been carried out with Rockwell hardness, Rc, exceeding 60.

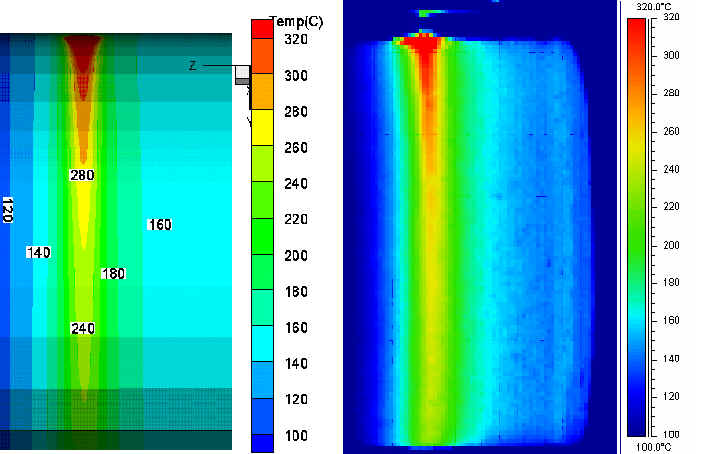

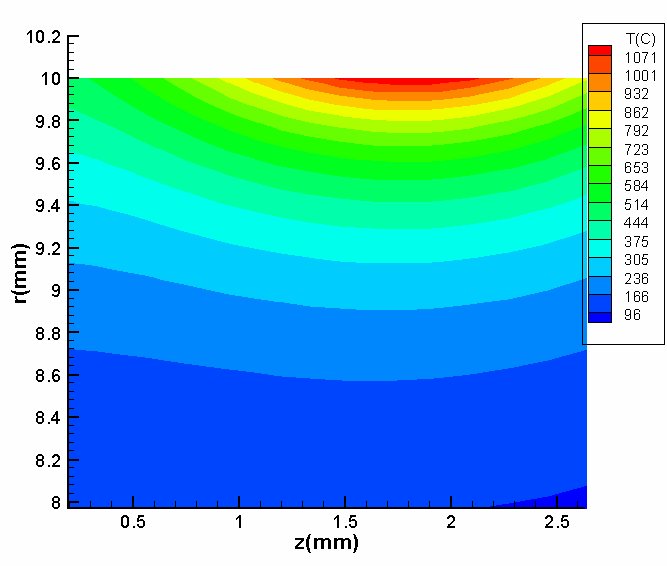

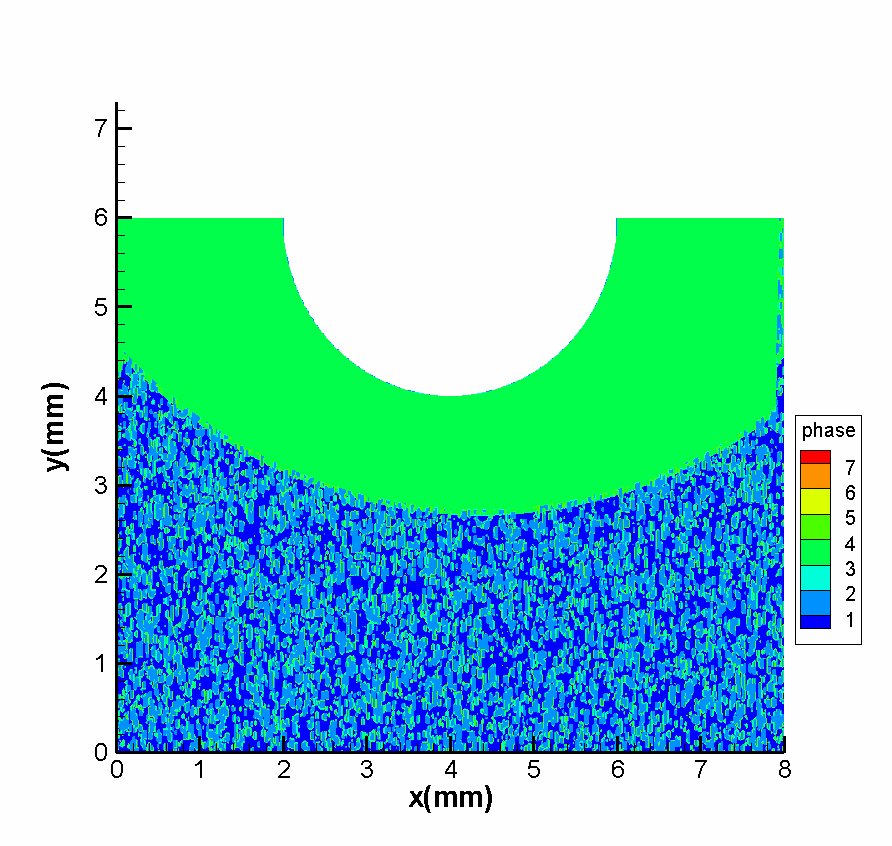

- A fully three dimensional thermo-kinetic-model has been developed and validated (see the

middle figure below), which provides the resultant microstructure and

hardness distribution.

- A back-tempering model has been developed to predict

microstructure change during the tempering process and integrated with

the thermo-kinetic model. The model can be used to optimize the overlapping patterns of

the laser

beam to achieve the most uniform hardness distribution.

- Experimental facilities have been developed for hardening various parts

with complex geometry.

- Laser hardening and nitriding capabilities of Ti6Al4V have been successfully

demonstrated along with the development of a predictive

thermo-diffusion model.

- A numerical model has been developed to predict resultant residual

stresses and integrated with the thermo-kinetic-tempering model.

Back to Top |

|

Illustrations |

Predicted Results

|

Measured

hardened zone

|

Hardening Set-up

|

| SPONSORS National

Science Foundation

Purdue Research Foundation

Indiana 21st Century Research and Technolog

International Truck and Engine

Rolls Royce Corp

|

Back to Top |