Phase Change Materials as Thermal Buffers for Power Electronics Modules with Transient Heat Loads

Phase Change Materials as Thermal Buffers for Power Electronics Modules with Transient Heat Loads

| Event Date: | July 21, 2025 |

|---|---|

| Authors: | M. Bhatasana and A. Marconnet |

| Journal: | Energy Conversion & Management |

| Paper URL: | Link to Full Text |

M. Bhatasana and A. Marconnet, Energy Conversion & Management, vol. 343, 119931, 2025.

DOI: 10.1016/j.enconman.2025.119931

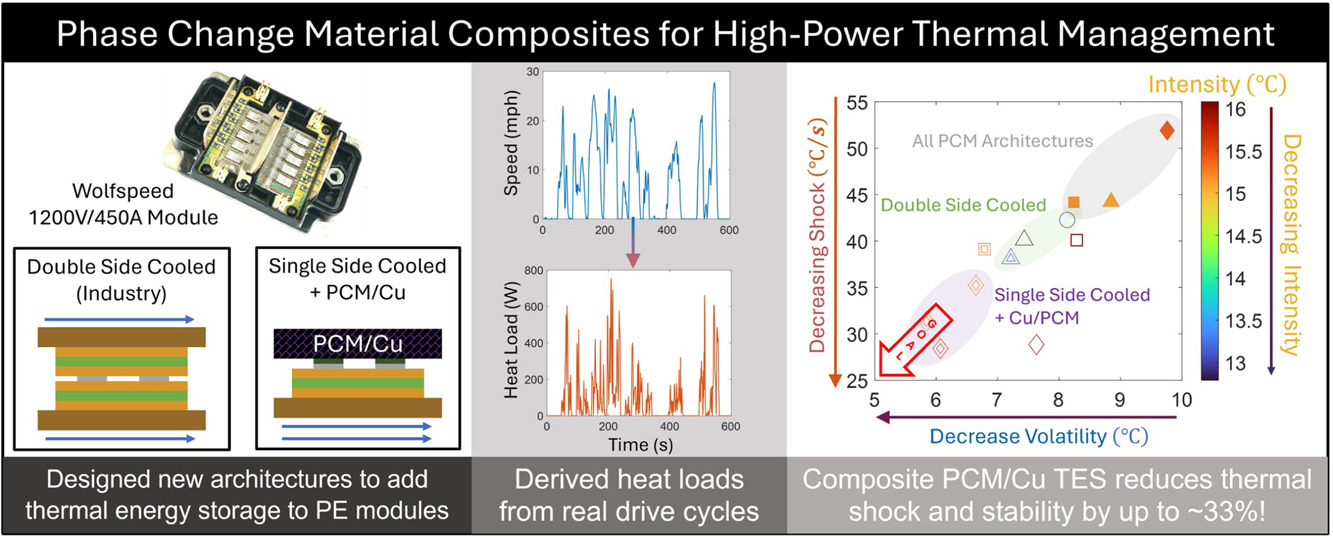

Due to increasing power densities and dynamic power profiles, thermal management plays an increasingly crucial role in power electronics modules, especially for automotive applications. Phase change materials (PCMs) have emerged as a promising option for effective thermal management in these modules. However, there is a gap in understanding the thermal behavior of these modules when using PCMs, specifically in considering realistic device geometries, and power profiles. In this paper, we evaluate the thermal performance of new module architectures that include PCM-based thermal energy storage (TES) in comparison to conventional architectures. We analyze the thermal performance under realistic transient heat loads derived from drive cycles and utilize three performance metrics for holistic performance comparison: the time-averaged maximum temperature rise, the maximum rate of temperature rise, and the standard deviation of the transient temperature response. There are trade-offs between the performance metrics for different architectures. Integrating liquid cooling on both sides of the device (i.e., double-side cooled (DSC)) demonstrated significant reductions in the overall operating temperature (both with and without integrated TES) compared to the single-side cooled (SSC) architectures. Depending on the drive cycle and configuration, the DSC architecture can lead to up to a 26% decrease. Integrating thermal energy storage can lead to a thermal solution responsive to transient drive cycles. Specifically, adding a composite copper/PCM TES directly on the heat-generating die while maintaining the single-sided liquid cooling path minimizes the thermal resistance pathway from the hot spot to the TES. This SSC+TES configuration functions effectively as a thermal shock absorber and temperature stabilizer suppressing the maximum temperature spike by up to 33% and stabilizing temperature fluctuations by up to 32% compared to the baseline DSC architecture (and reducing each of these metrics by up to ~65% compared to the conventional SSC architecture). Different drive cycles benefit from TES to various degrees. The SSC with TES proved highly effective in managing thermal loads in the stop-and-go drive cycles, consistently reducing thermal peaks resulting from aggressive driving conditions. Beyond improved thermal management, integrating a PCM-TES also enables the recovery of waste heat from power electronics modules. This waste heat can be utilized for cabin heating or battery warming, thereby decreasing additional energy drawn from the battery.