Impact of Thermal Cycling on Phase-Change Material (PCM) based Thermal Management Systems

Impact of Thermal Cycling on Phase-Change Material (PCM) based Thermal Management Systems

| Event Date: | March 1, 2026 |

|---|---|

| Authors: | P. Tripathi and A. Marconnet |

| Journal: | Journal of Electronic Packaging |

| Paper URL: | Link to Full Text |

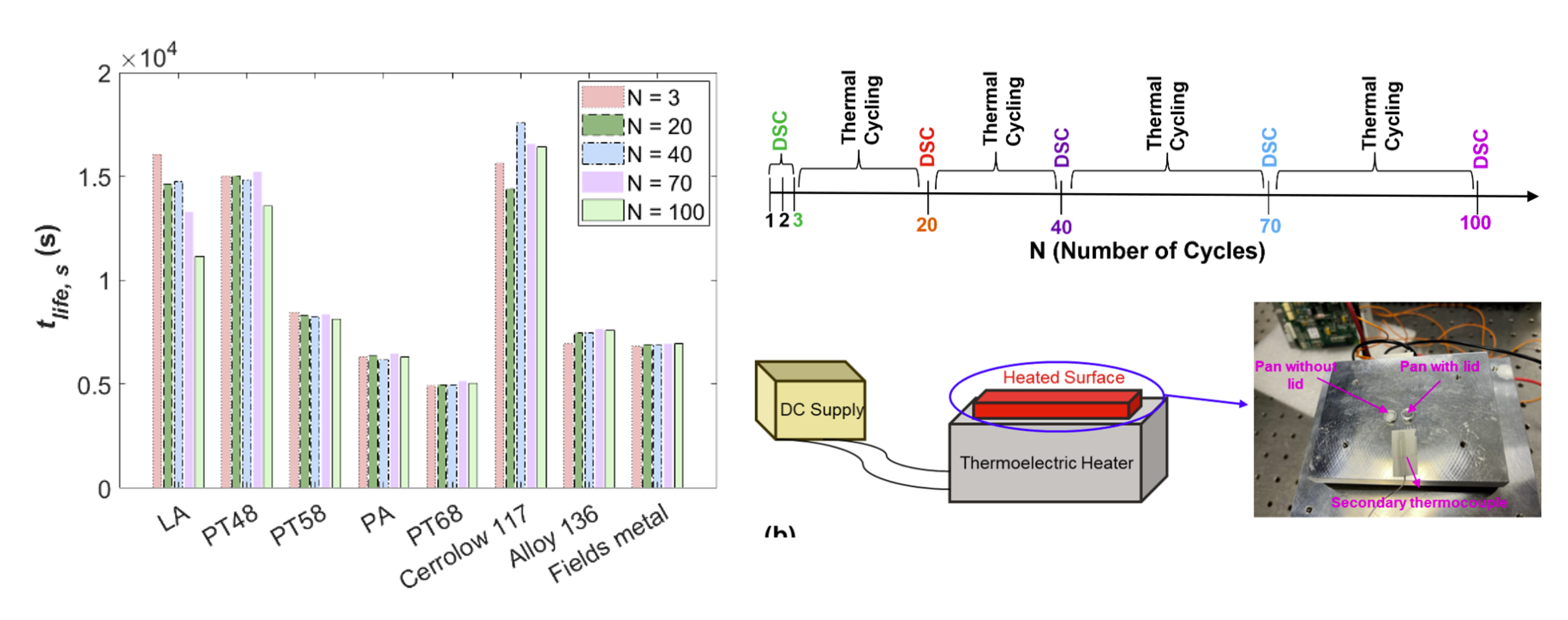

Degradation of phase change materials (PCMs) is critical in the design of thermal management systems. Although some previous studies have explored the long-term stability of PCMs, most have performed thermal cycling in thermostatic chambers, which may not simulate the actual heating boundary conditions in real systems. In the present study, first, we experimentally analyze the impact of thermal cycling on the melting and solidification characteristics of the PCMs using differential scanning calorimetry and a thermoelectric heat sink. The DSC response is measured at the beginning-of-life and after the PCM is cycled through operational temperatures for up to 100 cycles. To make the study comprehensive, 8 organic and 3 metallic PCMs are considered. Second, we numerically predict the effective performance of a composite PCM (i.e., metal foam impregnated with PCM) based thermal management system (TMS) by incorporating the measured properties (such as latent heat, glide in the melting temperature, and hysteresis of PCM) to ascertain the effect of thermal cycling on the real-time performance of the system. Finally, we demonstrate the applicability of analytical methods in analyzing the composite PCMs subjected to thermal cycling. Overall, we found that commercially available organic PCMs and metal alloys show more consistent performance with cycling compared to readily available fatty acids such as lauric acid. Ultimately, for PCMs subjected to repetitive thermal cycling, the selection process should aim for a balance of low temperature rise during heating and short recharging/solidification time for efficient and durable PCM-based TMSs.