Experimental characterization of thermal grease degradation between warped mating surfaces in power-cycled assemblies

Experimental characterization of thermal grease degradation between warped mating surfaces in power-cycled assemblies

| Event Date: | January 1, 2026 |

|---|---|

| Authors: | R. Kulkarni, N.P. Gronowski, and A.M. Marconnet |

| Journal: | Applied Thermal Engineering |

| Paper URL: | Link to Full Text |

R. Kulkarni, N.P. Gronowski, and A.M. Marconnet, Applied Thermal Engineering, Accepted and In Press, 2026.

DOI: 10.1016/j.applthermaleng.2026.129742

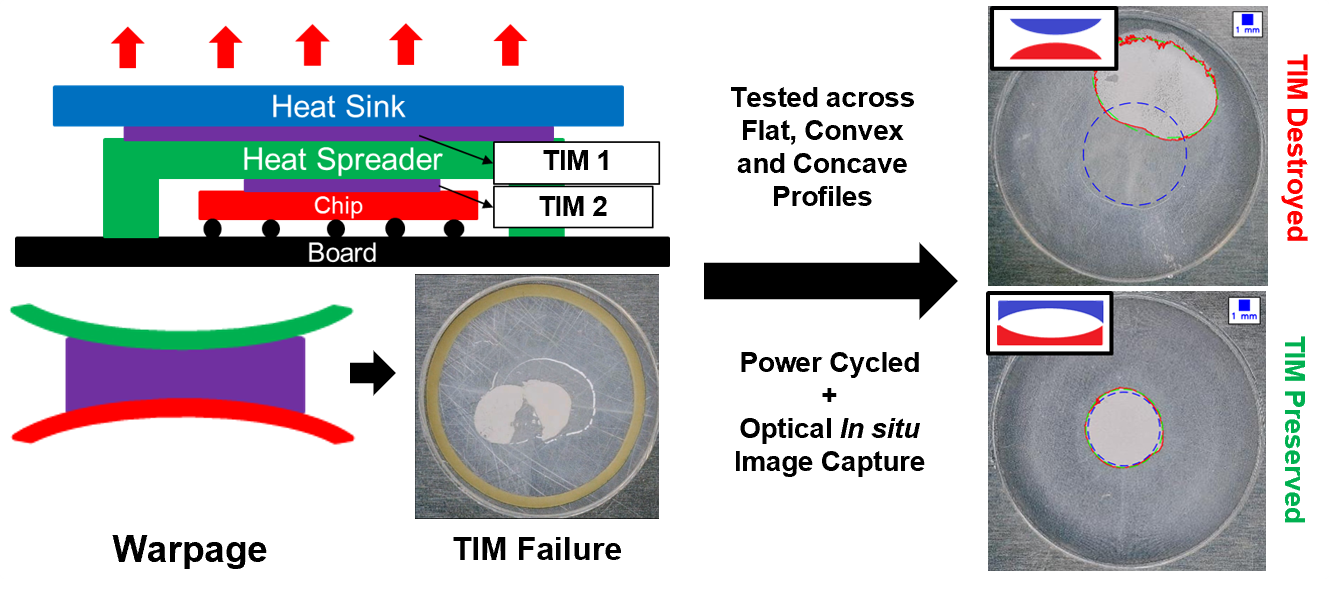

Thermal interface materials (TIMs) are crucial for effective heat transfer within electronic packages. Although TIMs enhance heat transfer at the beginning of life, they often degrade over time because of thermo-mechanical stresses in the system. Past studies on generally evaluated the reliability of TIMs applied between two flat, parallel surfaces. But in an actual package, components have inherent warpage and heat sinks are not perfectly flat. However, the impact of this non-flatness on the degradation of TIMs is not well understood. Thus, this study compares the visual degradation of thermal grease under non-flat surface profiles, in a power cycling environment and indicates non-flatness brings results different from flat mating substrates. The grease is inserted between a metal heater and an air-cooled (transparent) lens (that mimics the heat sink). The curvatures of both the die and the lens are precisely controlled (flat, convex, or concave). Power cycling causes voids, cracks, and movement of the TIM and this structural evolution is recorded with a digital microscope through the transparent lens. The non-flat mating surfaces lead to non-uniformity and motion of the thermal grease. Generally, curvatures that ensure the bondline is thickest at the center of the heater generally reduce the degradation as the decreasing bondline thickness from the center to edge prevents the grease from flowing outward. In contrast, severe degradation is observed when the center has the thinnest local BLT and the highest local pressures. Ultimately, these results demonstrate that controlling surface flatness or warpage is critical to controlling the degradation of thermal greases.