Probability of Detection (POD) Study for Bridge Inspection Related to Steel Bridges

To determine the current performance of inspectors with the industry's present standards of training, a comprehensive Probability of Detection (POD) study is underway to determine the likelihood of inspectors finding cracks, surface corrosion and weld defects of various sizes on a bridge structure. This study will test multiple inspectorsâ abilities to identify different defects under various environmental conditions on a bridge structure. The study will provide state transportation agencies, as well as private inspection agencies, invaluable information regarding typical inspector performance. The outcomes will be used to establish procedures to improve inspection reliability, and develop inspector performance-based certification criteria and procedures.

Sponsor: Indiana Department of Transportation (INDOT)

Faculty Investigator: Robert Connor

Graduate Students: Julie Whitehead & Luke Snyder

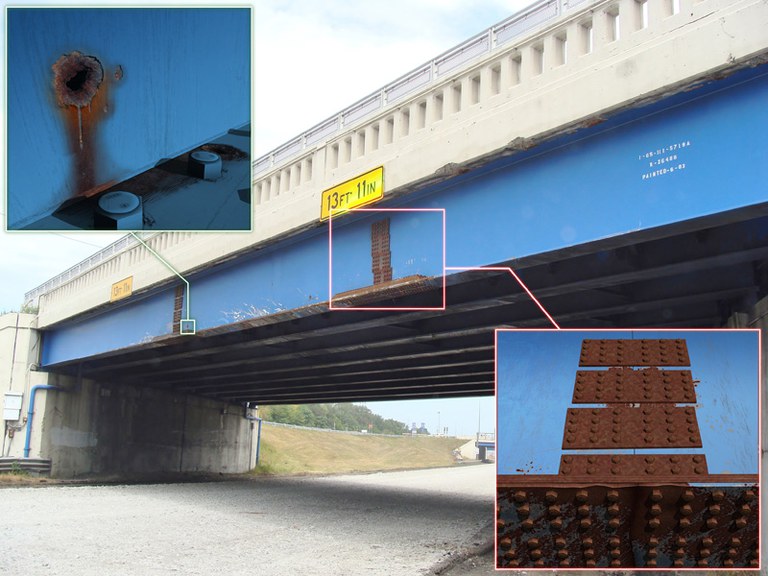

An inspector’s ability to correctly identify surface and internal defects in steel bridge components is critical to protecting public safety. Ensuring that these inspectors are properly trained and adequately prepared to detect these defects in locations that are difficult to access and/or in unfavorable environmental conditions must be a high priority. In order to determine the current performance of inspectors, with the industry’s present standards of training, a comprehensive Probability of Detection (POD) study is underway to determine the likelihood of inspectors finding cracks, surface corrosion and weld defects of various sizes on a bridge structure. This study is the first of its kind in the highway bridge inspection industry. In order to develop meaningful data that indicates which type and size defects that a typical bridge inspector is likely to find, the specimens to be inspected will be suspended from a steel frame 25 feet above ground, see Figure 1. The specimens will be arranged to simulate field conditions so that various inspection environments, including lighting issues between girders, access concerns and surface quality, can be considered. The defective specimens will have various coatings, crack sizes and crack types to represent bridges that are currently in service in the field. These specimens with defects will be randomly intermixed among defect-free specimens on the three 80-foot girders of the simulated bridge. The study will provide state transportation agencies, as well as private inspection agencies, invaluable information regarding typical inspector performance. Furthermore, the outcomes will be used to establish procedures to improve inspection reliability, and develop inspector performance-based certification criteria and procedures.

Figure 1

Each of the specimens that will be installed on the POD Fixture will be fabricated at a steel fabrication shop and then processed at Purdue University’s Bowen Laboratory where varying types of fatigue cracks will be created. Figure 2 demonstrates an example of one such crack. In addition to a variety of cracks on multiple detail types, two different steel surface types will be included in the research, namely painted steel and unpainted weathering steel. Furthermore, a number of bridge girders and sections from demolished bridges have been donated to S-BRITE Center that will be included for inspection of corrosion and other general damage.

Figure 2

In addition, the S-BRITE Center Research Team is joining with experts at Purdue University’s Envision Center to explore the possibilities of data visualization and virtual simulation of various environments for bridge inspection. The S-BRITE Center and Envision Center have been working to create prototype models. Figure 1 above is a rendering created by Envision Center. Figure 3 below shows another preliminary prototype. The S-BRITE Research Team believes that these virtual models have the potential to significantly assist in improving inspection data quality by allowing inspectors to perform detailed inspections either via the web or by visiting the Envision Center’s “Cave”. The Cave is the Envision Center’s reconfigurable Virtual Theater where a user becomes immersed in the virtual reality environment by way of the floor and three upright screens that all support Active Steroscopic 3D Projections.

Figure 3

The following links provide examples of the preliminary prototypes that the Envision Center has created. Each link will require the installation of the Unity web plug-in, which will be prompted once clicking the link. The first link provides an interactive built-up I-beam. The second link provides an interactive POD Fixture where the arrow keys can be used to navigate the field.

Steel for the POD Fixture and inspection specimens has been generously donated by Steel Dynamics, Inc., Structural and Rail Division, out of Columbia City, Indiana.

Galvanization for the POD Fixture has been generously donated by AZZ Galvanizing, Inc.