Catalysis and Biocatalysis

Catalysis and Biocatalysis

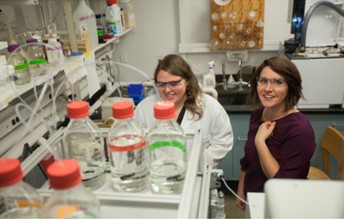

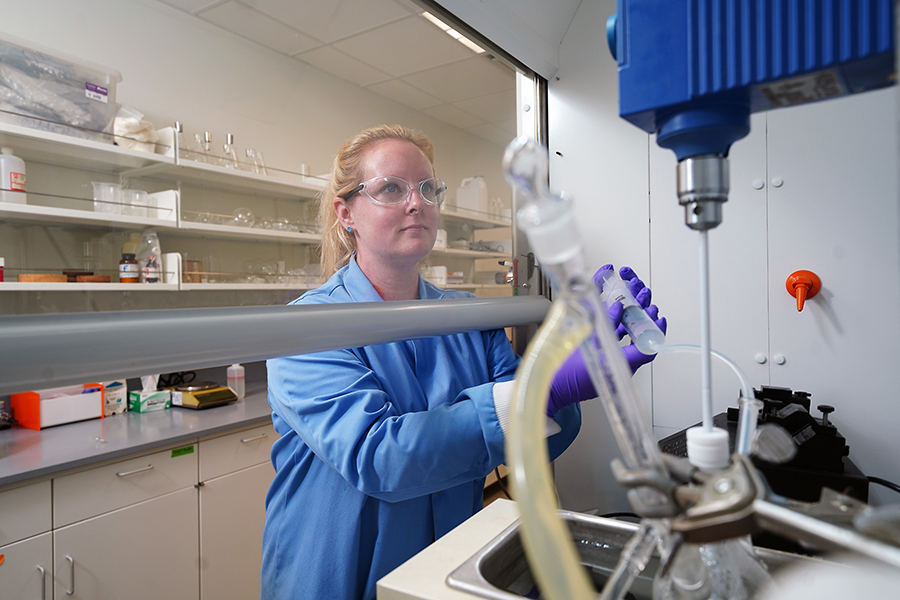

Enzyme reactions may be carried out at scales ranging from 50 mL (shake-flask) to 10 L at temperature and pH-co ntrolled conditions. In addition, we also deploy reactors for modifying natural products to esters and long-chain, plant-derived fatty acids into bio-lubricants via transesterification, epoxidation, ketonization, and estolide formation. Related research is examining synthesis of 5-hydroxymethylfurfural (HMF) from milled corn, and from cellulosic materials. HMF is utilized as a food additive, although major applications are directed to its catalytic conversion to platform chemicals, fuels and fine chemicals.

High-pressure batch reactors are used for fundamental research on liquid hot water pretreatments of biomass materials, and other high temperature and high-pressure reactions for pretreatment of lignocellulosic biomass at temperatures of up to 220C and pressures up to 23 bar. Liquid hot water enables opening up the structure of lignocellulosic materials from agricultural residues, food processing and dry mill co-product streams, and woody materials in order to enhance accessibility and reactivity with respect to cellulolytic enzymes and for preparing fermentation substrates.

Reaction and bioreaction engineering are fundamental to our research and student training. Although specific applications have evolved over the years, current targets include fermentation, cell culture, catalytic conversion of agricultural materials to sustainable liquid fuels, and bioproducts for food and industrial applications. Biorenewable fuels range from ethanol to biodiesel and sustainable aviation fuel, to bioproducts for formulating carbon-negative cements. Value-added food components are recovered by extraction of nutraceuticals from agricultural residues and by-products.

Extraction at lab scale enables pinpointing of process conditions for translation to larger scale, catalytic hydrothermal and pressure treatments. Characterization and analysis for both catalytic and biocatalytic reactions that provides supporting data required for process modeling and for calculation of material and energy balances, which in turn provide the supporting information for calculation of techno-economic analysis (TEA) and life-cycle analyses (LCA). TEA and LCA are central to evaluating both catalytic and biological processes, respectively, since these analysis give a first indication of process costs and carbon balances that are central to the overall decarbonization of manufacturing processes.

Renewable diesel (also called green diesel) is produced from fats/oils, including fats/oils with high FFA content, through hydrogenation, deoxygenation, isomerization, and thermally/catalytically cracking. Because the carbon chain length of the typical hydrocarbons from fats/oils ranges from 15 to 18, the high melting points of these hydrocarbons result in poor low-temperature performance. Thermal/catalytic cracking and isomerization to form shorter carbon-chain length hydrocarbons and iso alkanes with good low-temperature performance and that meet specifications of the resulting green/renewable diesel for winter season use, kerosene, or aviation fuels is carried out in batch and continuous reactors.

A key biocatalytic reaction is the enzyme hydrolysis with processes that utilize enzyme hydrolysis or modification of lignin, cellulose, and hemicellulose in biomass continues to be studied by our laboratory. Substrates range from agricultural residues (corn stover, sugar cane bagasse, soybean hulls, grasses), mixed hardwoods, and corn fiber (by product of dry milling or wet milling) to proteins. Hydrolysis of proteins, lipids, and polysaccharides using proteolytic, lipolytic, or amylase / cellulase / hemicellulase enzymes enables rapid ultrafiltration of food extracts and - in turn - facilitates rapid detection of food pathogens by removing biopolymers that cause fouling of membranes. The incubation of cellulolytic and proteolytic enzymes with corn kernels in water has been shown to enable wet milling (i.e., fractionation) of corn kernels into starch, pericarp, gluten and oils without cooking and with minimal addition of chemicals.

Most recently, artificial intelligence (AI) and machine learning (ML) has been introduced to LORRE. This approach, known as reverse synthesis, facilitates enzymes specifically designed for use in catalyzing production of value-added products in a cell-free environment. Once deigned, nucleic acid sequences (i.e., DNA) is generated elsewhere and then cloned into the host microorganism. These proteins are then produced by fermentation of the genetically modified bacteria (AI/ML Biocatalytic Pathway Design and Synthesis) in sufficient quantity to facilitate proof of concept, i.e. testing. The systems of enzymes obtained in this manner have the potential to catalyze synthesis of key chemical intermediates for production of polymers and biodegradable plastics.