CTRC Breakthroughs

Thermal Interfaces

Research Topics

Microscale Transport and Microchannels

Electrically Actuated Microscale Flows

Thin-Film Transport, Wicks and Heat Pipes

Novel Air and Impingement Cooling Approaches

Surface and Interface Engineering

Thermal Materials R&D

Thermal Interfaces

Small-Scale Refrigeration

Exploratory and Novel Concepts

Renewable and Sustainable Energy

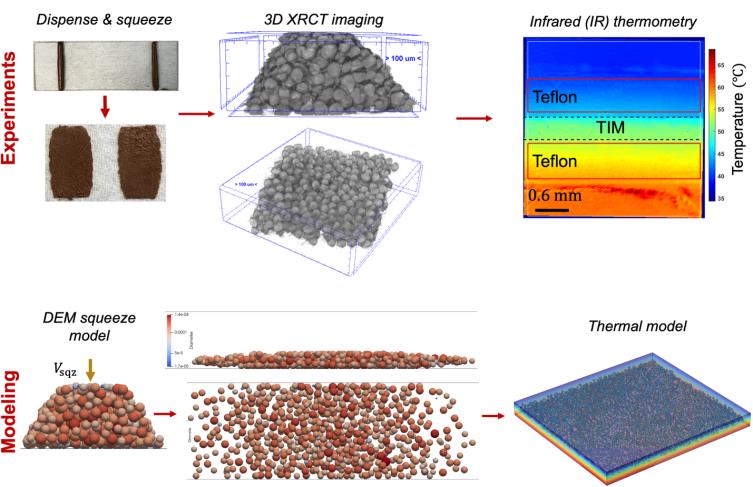

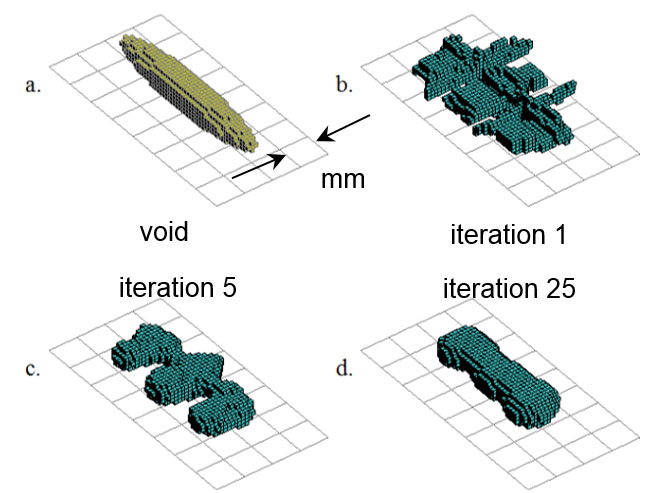

Optimization of Thermal Interface Material’s Particle Features and Dispense Mechanism for Enhanced Heat Dissipation

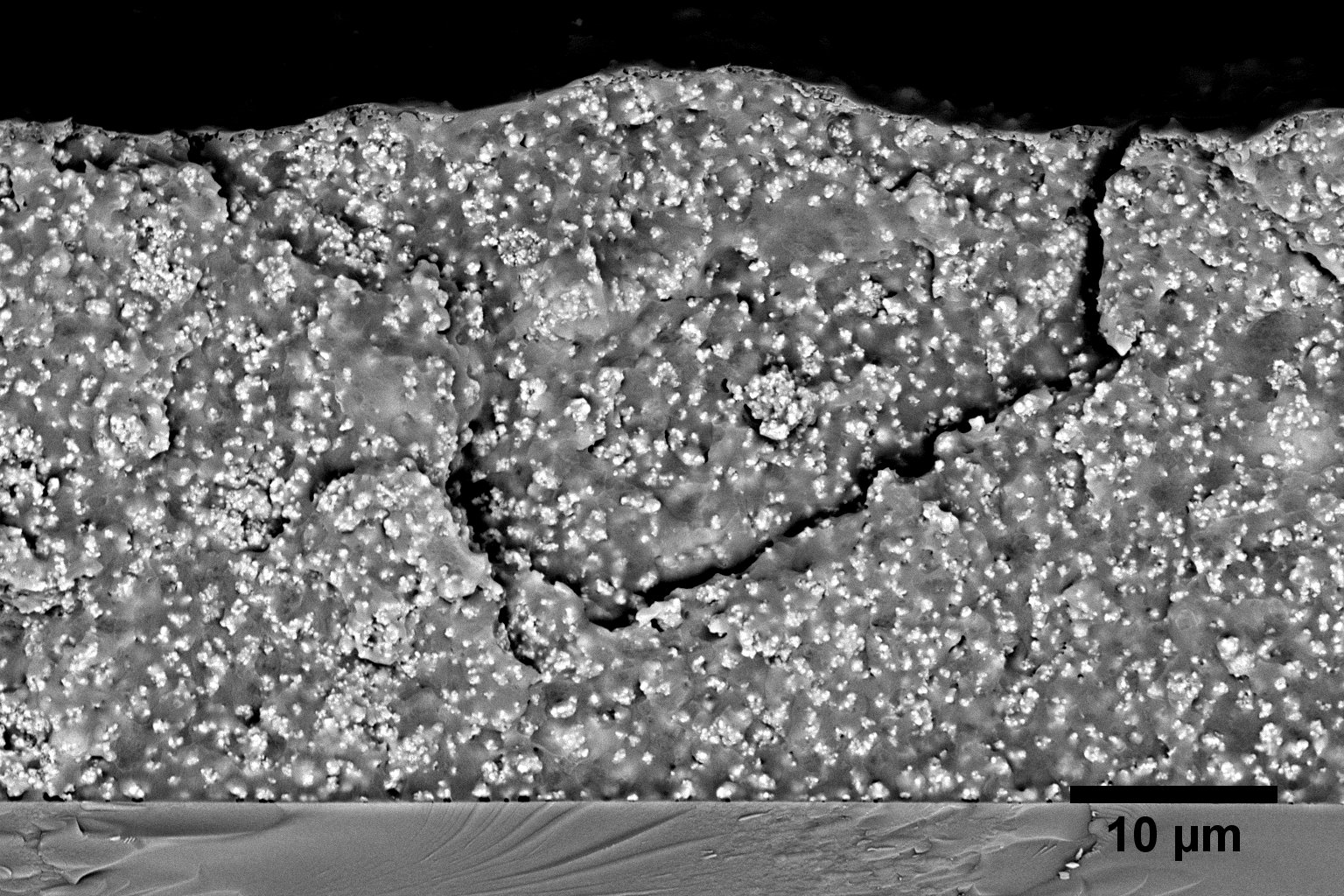

Thermal interface materials (TIMs) improve thermal

contact in electronics packages. For TIMs consisting

of particles suspended in a polymeric matrix, the

particle networks within the material evolve through

the assembly process. There is a lack of quantitative

understanding of particle rearrangements within the

TIM induced by these assembly processes and the

resulting effect on the thermal performance during

operation. The objective of this project is to

fundamentally understand the impact of particle

redistribution within the TIM during dispense and

squeeze processes on the thermal conductivity,

through experimental and modeling approaches. Experimentally, X-ray micro computed tomography (XRCT)

provides insight into the distribution of particles before and after squeezing. In parallel, an open-source

software, MFIX, was modified to simulate constant velocity squeezing of TIMs with a one-way fluid-particle

coupling via drag force. A finite element thermal conduction model was developed using COMSOL to predict

bulk TIM thermal conductivity. Ultimately this project is the first step in developing both experimentallyvalidated microstructure and thermal models that can be used to optimize TIM formulation and application

process.

Thermal interface materials (TIMs) improve thermal

contact in electronics packages. For TIMs consisting

of particles suspended in a polymeric matrix, the

particle networks within the material evolve through

the assembly process. There is a lack of quantitative

understanding of particle rearrangements within the

TIM induced by these assembly processes and the

resulting effect on the thermal performance during

operation. The objective of this project is to

fundamentally understand the impact of particle

redistribution within the TIM during dispense and

squeeze processes on the thermal conductivity,

through experimental and modeling approaches. Experimentally, X-ray micro computed tomography (XRCT)

provides insight into the distribution of particles before and after squeezing. In parallel, an open-source

software, MFIX, was modified to simulate constant velocity squeezing of TIMs with a one-way fluid-particle

coupling via drag force. A finite element thermal conduction model was developed using COMSOL to predict

bulk TIM thermal conductivity. Ultimately this project is the first step in developing both experimentallyvalidated microstructure and thermal models that can be used to optimize TIM formulation and application

process.

TIM Design for Optimized Thermal and Mechanical Properties

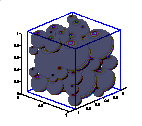

While, in general, increasing particle loading is required to meet the expected target of effective thermal conductivities, the increased effective elastic modulus due to increased particle loading, which together with the thinned dies has the potential to cause warping or fracture of the dies. Thus, there is a need to carryout systematic thermal-mechanical design trade-off studies of the particle filled thermal interface materials (TIMs). Thermal conduction behavior and flow behavior are directly related to particle filler loading. Microstructures with ultrahigh volume fractions are needed to effectively predict the behavior of the particulate systems. In this project, we have successfully generated microstructures with ultrahigh volume fractions and analyzed the effective thermal conductivity and elastic modulus of these TIMs with high particle loading. The analysis has also been extended to TIMs with ellipsoidal fillers.

While, in general, increasing particle loading is required to meet the expected target of effective thermal conductivities, the increased effective elastic modulus due to increased particle loading, which together with the thinned dies has the potential to cause warping or fracture of the dies. Thus, there is a need to carryout systematic thermal-mechanical design trade-off studies of the particle filled thermal interface materials (TIMs). Thermal conduction behavior and flow behavior are directly related to particle filler loading. Microstructures with ultrahigh volume fractions are needed to effectively predict the behavior of the particulate systems. In this project, we have successfully generated microstructures with ultrahigh volume fractions and analyzed the effective thermal conductivity and elastic modulus of these TIMs with high particle loading. The analysis has also been extended to TIMs with ellipsoidal fillers.

Polymer-Metallic Hybrids for Thermal Interface Applications

Polymer-based thermal interface materials (TIMs) filled with thermally conductive particles are generally used in electronic devices. However, mismatch in the coefficient of thermal expansion (CTE) is a common problem, causing thin film delamination during a system’s lifecycle. In order to develop polymer-metallic TIMs, this project emphasized the balance between mechanical and thermal performance. We investigated various physical effects of polymer-based TIMs to access mechanical and thermal reliability. We also achieved various TIMs with different types of materials, which were nanoparticles and microporous foam as conductive networks.

Polymer-based thermal interface materials (TIMs) filled with thermally conductive particles are generally used in electronic devices. However, mismatch in the coefficient of thermal expansion (CTE) is a common problem, causing thin film delamination during a system’s lifecycle. In order to develop polymer-metallic TIMs, this project emphasized the balance between mechanical and thermal performance. We investigated various physical effects of polymer-based TIMs to access mechanical and thermal reliability. We also achieved various TIMs with different types of materials, which were nanoparticles and microporous foam as conductive networks.

Dry Contact Thermal Conductance Enhancement

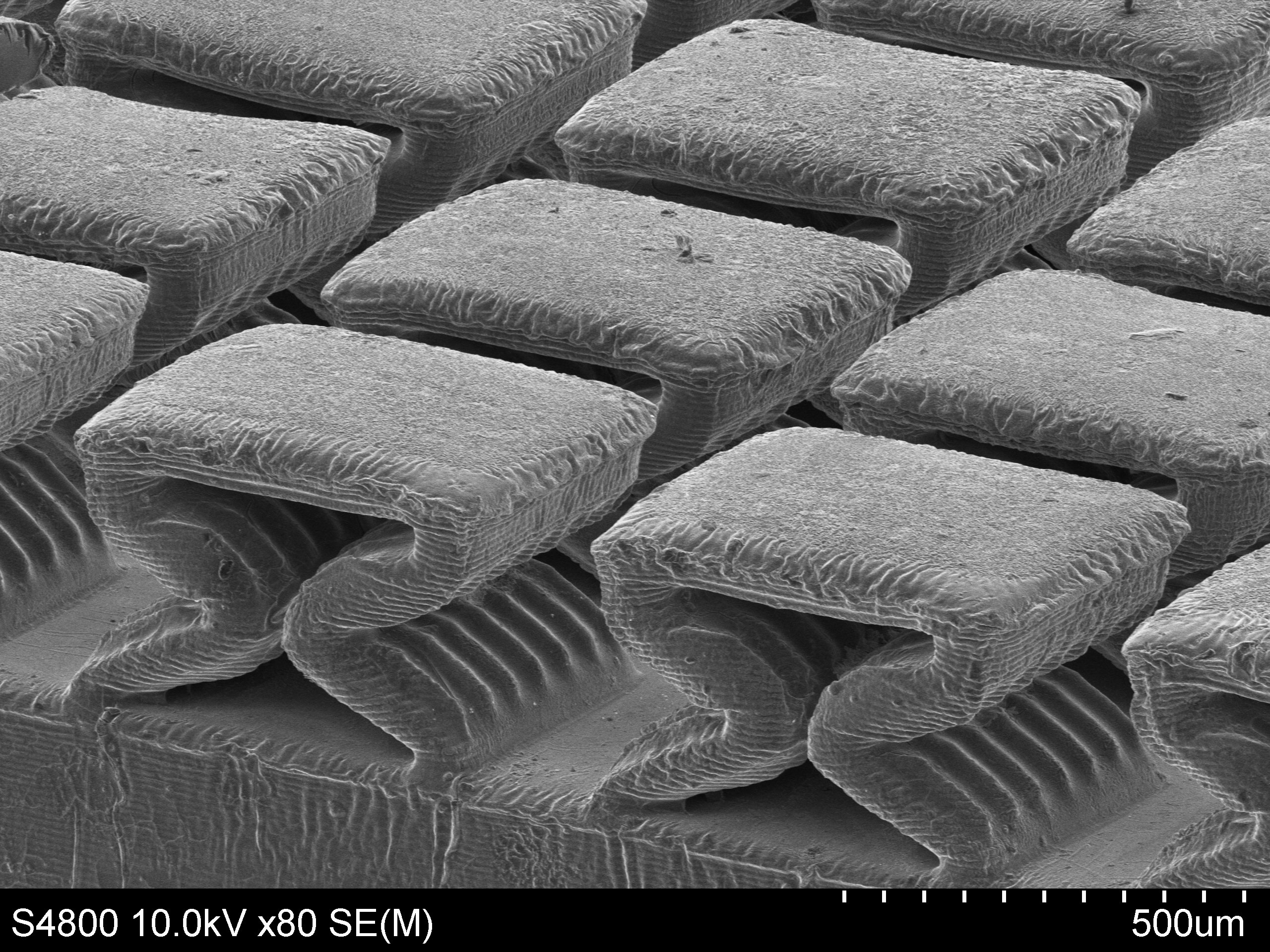

Thermal interface materials (TIMs) are commonly used to enhance thermal conductance across interfaces. However, wet TIMs and high compressive pressures are disallowed for ‘pluggable’ applications where the devices need to frequently slide into contact with the heat sinks. In this project, we developed a compliant dry TIM which can enhance the thermal conductance between nonflat and rough mating surfaces at a very low pressure of ~20 kPa. This TIM consists of an array of metallized polymer micro-springs which are fabricated using cost-effective micro-stereolithography (μSL) based techniques and electroless metal plating. Even for rough and nonflat interfaces, the dry TIM is able to achieve a thermal resistance equivalent to contact between highly polished and very flat surfaces (~300 mm2·K/W). The mechanical robustness of the dry TIM was evaluated, and the performance demonstrated when placed between pluggable optical module and its riding heat sink.

Thermal interface materials (TIMs) are commonly used to enhance thermal conductance across interfaces. However, wet TIMs and high compressive pressures are disallowed for ‘pluggable’ applications where the devices need to frequently slide into contact with the heat sinks. In this project, we developed a compliant dry TIM which can enhance the thermal conductance between nonflat and rough mating surfaces at a very low pressure of ~20 kPa. This TIM consists of an array of metallized polymer micro-springs which are fabricated using cost-effective micro-stereolithography (μSL) based techniques and electroless metal plating. Even for rough and nonflat interfaces, the dry TIM is able to achieve a thermal resistance equivalent to contact between highly polished and very flat surfaces (~300 mm2·K/W). The mechanical robustness of the dry TIM was evaluated, and the performance demonstrated when placed between pluggable optical module and its riding heat sink.

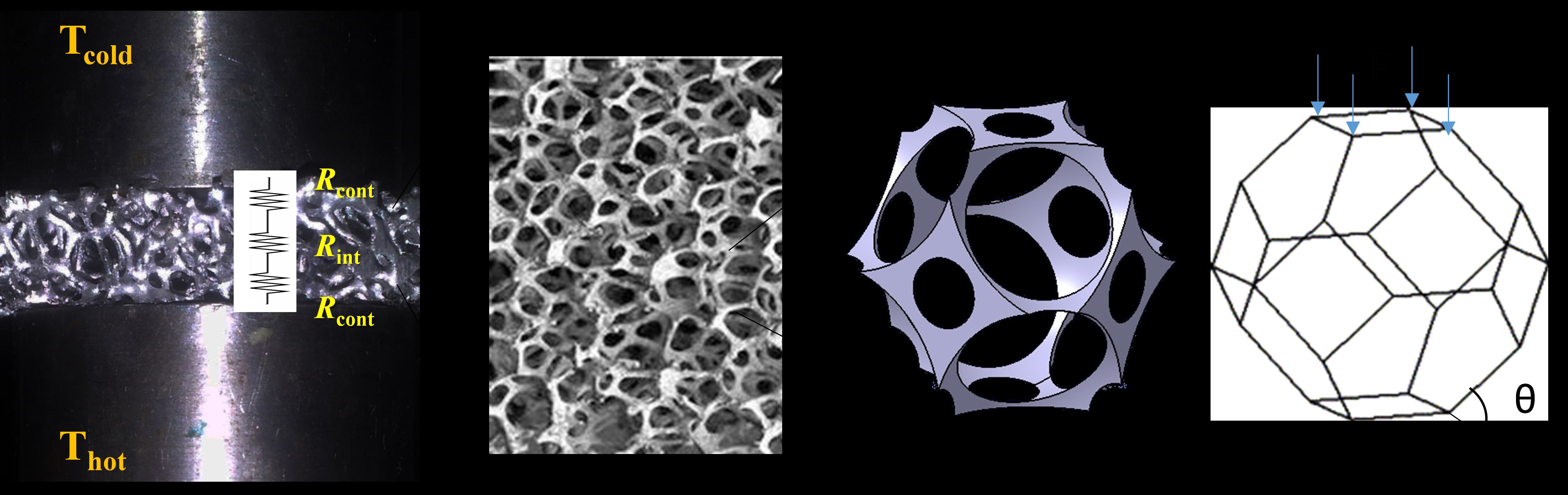

Porous Metal Thermal Interface Material

Metal foam structure has been shown to have good

mechanical compliance and relatively higher thermal conductivities making

it an ideal candidate for thermal interface material in

electronics cooling applications. Analytic

models were developed in order to predict apparent thermal and mechanical performance of the material generalized with respect to raw

material properties and porous geometries such as porosity and pore size.

Model predictions were validated through numerical simulations and correlated to the experimentation,

with which we refined the ASTM standard measurement setup and

additionally developed a new setup to take into account the

deformation information.

Additionally, multiple composite designs with phase change

material and thermal greases were tested with regards to their

effective thermal and mechanical properties were analyzed.

Metal foam structure has been shown to have good

mechanical compliance and relatively higher thermal conductivities making

it an ideal candidate for thermal interface material in

electronics cooling applications. Analytic

models were developed in order to predict apparent thermal and mechanical performance of the material generalized with respect to raw

material properties and porous geometries such as porosity and pore size.

Model predictions were validated through numerical simulations and correlated to the experimentation,

with which we refined the ASTM standard measurement setup and

additionally developed a new setup to take into account the

deformation information.

Additionally, multiple composite designs with phase change

material and thermal greases were tested with regards to their

effective thermal and mechanical properties were analyzed.

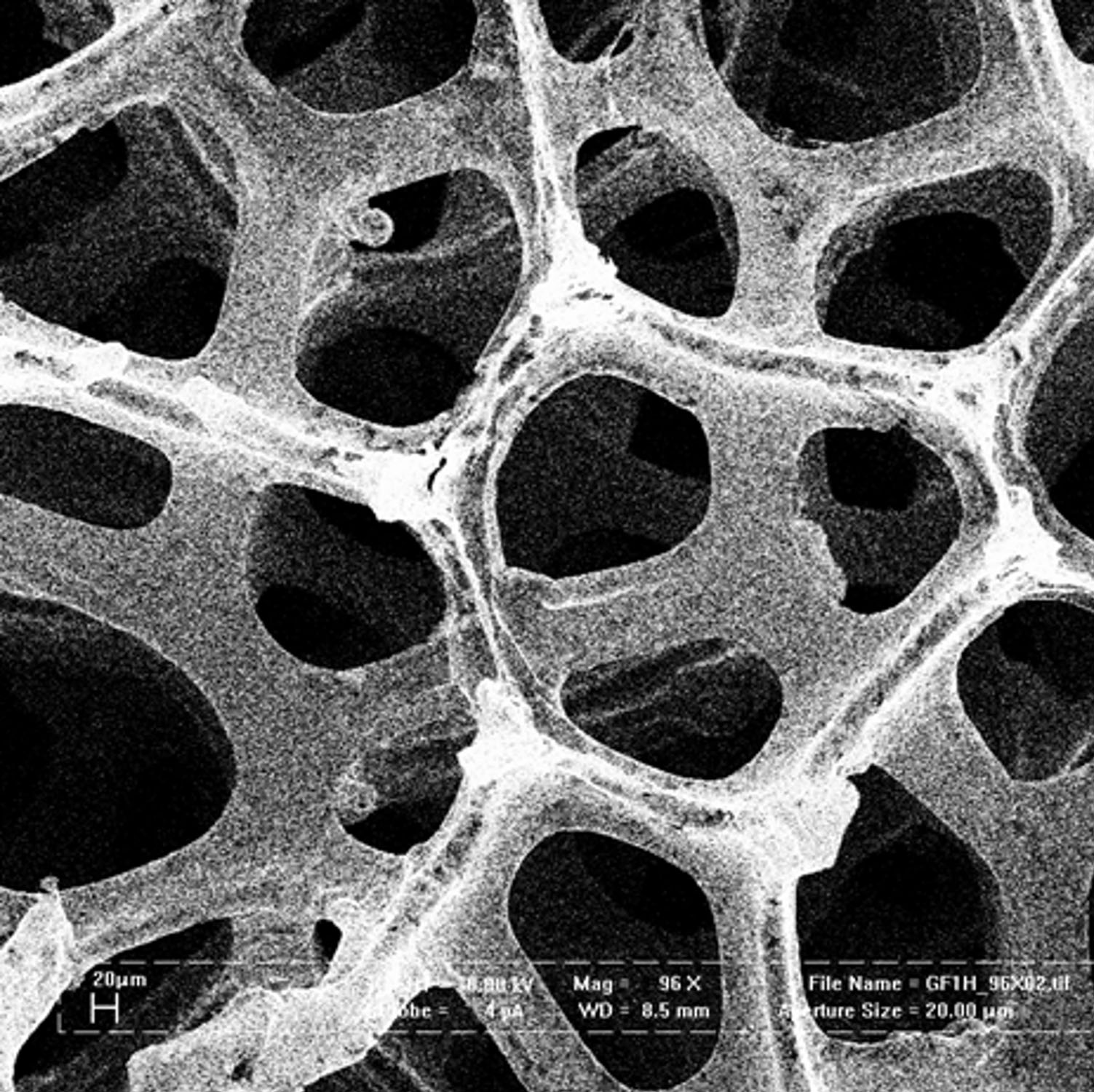

Three-Dimensional Graphene Networks Facilitate Efficient Heat Conduction at Thermal Junctions

Efficient heat dissipation becomes a crucial issue due to increase in

generated power density in modern electronic devices. Therefore,

high-performance TIMs are required to achieve efficient heat

conduction across thermal junctions (heat sources/sinks) by

filling in surface irregularities. In this project, graphene

networks prepared by chemical vapor deposition method were

investigated as thermal interface materials. The thermal resistance was characterized between graphene

networks and copper. The result indicates that graphene networks

can improve the heat transfer at interfaces between dissimilar

materials. Researchers also conducted systematic studies on thermal interface

resistance of graphene networks with various densities and

demonstrated their feasibility as thermal interface materials.

In addition, researchers investigated mechanical properties such

as compressive strength.

Efficient heat dissipation becomes a crucial issue due to increase in

generated power density in modern electronic devices. Therefore,

high-performance TIMs are required to achieve efficient heat

conduction across thermal junctions (heat sources/sinks) by

filling in surface irregularities. In this project, graphene

networks prepared by chemical vapor deposition method were

investigated as thermal interface materials. The thermal resistance was characterized between graphene

networks and copper. The result indicates that graphene networks

can improve the heat transfer at interfaces between dissimilar

materials. Researchers also conducted systematic studies on thermal interface

resistance of graphene networks with various densities and

demonstrated their feasibility as thermal interface materials.

In addition, researchers investigated mechanical properties such

as compressive strength.

Impedance-Based Visualization of Voids in Thermal Interface Materials

Thermal interface materials are an essential component of thermal

management of modern electronics systems. These materials tend

to degrade over time, reducing their effectiveness at conducting

heat. The application of capacitance imaging to the size scale

of a thermal interface material (~1 cm x ~1 cm x ~0.01 cm)

represents an innovative development for experimental

instrumentation. The technique may be used by researchers to

better understand the behavior of thermal materials subjected to

various stress conditions or as a quality control technique.

Embedded electrical sensors have been successfully used in a lab

environment to image either a thin layer of thermal grease or a

thick thermal pad while it is situated between two opaque

surfaces. Bubbles and other defects in the material may be

detected and imaged using image reconstruction algorithms.

Thermal interface materials are an essential component of thermal

management of modern electronics systems. These materials tend

to degrade over time, reducing their effectiveness at conducting

heat. The application of capacitance imaging to the size scale

of a thermal interface material (~1 cm x ~1 cm x ~0.01 cm)

represents an innovative development for experimental

instrumentation. The technique may be used by researchers to

better understand the behavior of thermal materials subjected to

various stress conditions or as a quality control technique.

Embedded electrical sensors have been successfully used in a lab

environment to image either a thin layer of thermal grease or a

thick thermal pad while it is situated between two opaque

surfaces. Bubbles and other defects in the material may be

detected and imaged using image reconstruction algorithms.

Designing Transient Liquid Phase Sintering Systems for Power Electronics

In transient liquid phase sintering, a low melting temperature

metal powder and an organic flux are mixed with high melting

point alloys in particle form. When the temperature is increased

above the melting temperature of the low melting point phase, a

new compound begins to form at the interface between the liquid

and the solid. This project developed model paste formulations

for the development of new electrical and thermal technology

based on transient liquid phase sintering for attaching cooling

systems to chips, semiconductor dies, and substrates in power

electronics. Thermodynamic software and down-selection criteria

for specific applications were developed and applied to evaluate

novel alloy formulations for these uses.

In transient liquid phase sintering, a low melting temperature

metal powder and an organic flux are mixed with high melting

point alloys in particle form. When the temperature is increased

above the melting temperature of the low melting point phase, a

new compound begins to form at the interface between the liquid

and the solid. This project developed model paste formulations

for the development of new electrical and thermal technology

based on transient liquid phase sintering for attaching cooling

systems to chips, semiconductor dies, and substrates in power

electronics. Thermodynamic software and down-selection criteria

for specific applications were developed and applied to evaluate

novel alloy formulations for these uses.

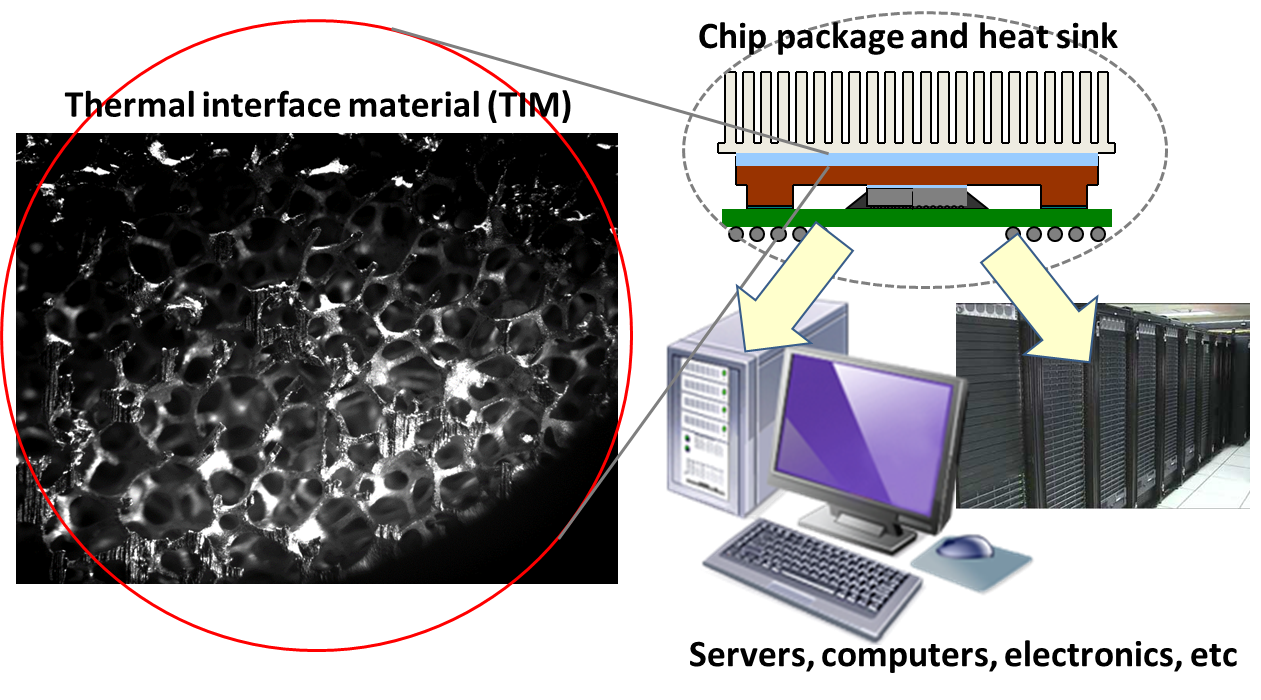

Flexible Foam New Thermal Interface Material

This project developed a new set of analytic models to predict the

performance of porous aluminum structure (foam) as a thermal

interface material. The models include the mechanical compliance

and the effective thermal conductivity of the foam by a

combination of physical model validated with numerical and

experimental data. The developed model aids in selecting the

best geometry with the combination of materials in foam

structure, which will ultimately enable the industry with the

most cost effective solution for electronics cooling. The chart

including the microscope image of the sample foam shows the

example of placement and method to utilize the aluminum foam in

the electronic cooling.

This project developed a new set of analytic models to predict the

performance of porous aluminum structure (foam) as a thermal

interface material. The models include the mechanical compliance

and the effective thermal conductivity of the foam by a

combination of physical model validated with numerical and

experimental data. The developed model aids in selecting the

best geometry with the combination of materials in foam

structure, which will ultimately enable the industry with the

most cost effective solution for electronics cooling. The chart

including the microscope image of the sample foam shows the

example of placement and method to utilize the aluminum foam in

the electronic cooling.

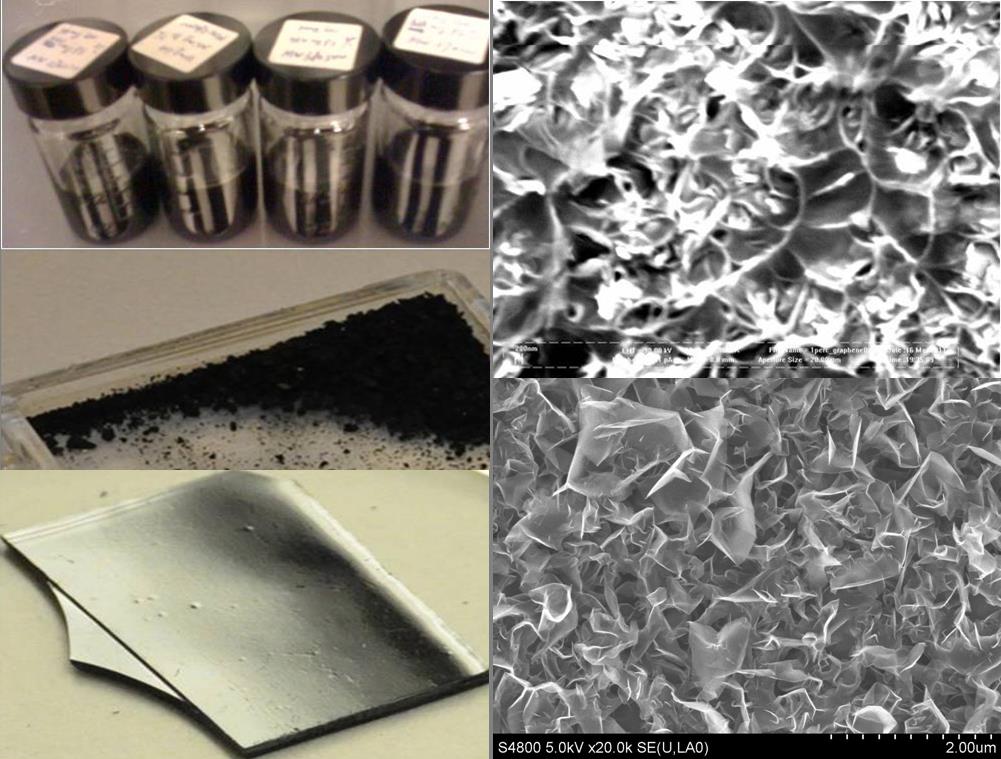

Graphene-Based Thermal Interface Materials

Graphene, a single atomic layer of graphite with honeycomb lattice

structure, exhibits very high thermal conductivity (~3000-5000

W/m-K), which renders it an outstanding candidate for Thermal

interface materials (TIMs) applications. Graphene composite

shows significant increase of thermal conductivity when the

volume percent of graphene is increased. Vertically grown

graphene shows superior performance, with a thermal resistance

in the order of 1 mm2 K/W, which is better than

available commercial thermal interface materials. This figure is

the synthesis of graphene composite, which includes the

preparation of graphene solution, the drying of the powders, and

the hot pressing to form nanocomposite. Shown in the right lower

corner is the vertical graphene petals prepared using chemical

vapor deposition (CVD).

Graphene, a single atomic layer of graphite with honeycomb lattice

structure, exhibits very high thermal conductivity (~3000-5000

W/m-K), which renders it an outstanding candidate for Thermal

interface materials (TIMs) applications. Graphene composite

shows significant increase of thermal conductivity when the

volume percent of graphene is increased. Vertically grown

graphene shows superior performance, with a thermal resistance

in the order of 1 mm2 K/W, which is better than

available commercial thermal interface materials. This figure is

the synthesis of graphene composite, which includes the

preparation of graphene solution, the drying of the powders, and

the hot pressing to form nanocomposite. Shown in the right lower

corner is the vertical graphene petals prepared using chemical

vapor deposition (CVD).

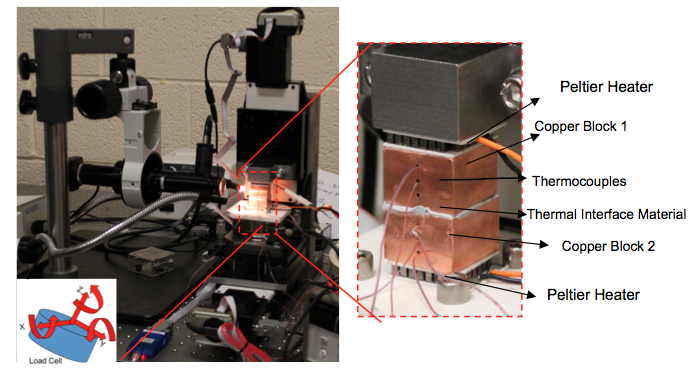

Performance and Reliability of Thermal Interface Materials

This project has developed a test procedure to simultaneously

characterize thermal and non-Newtonian flow behavior of

polymeric thermal interface materials (TIMs). Also, reliability

characterization of representative polymeric TIMs using the

developed test procedure after exposure to high temperature bake

as well as thermal cycling of the materials. The picture depicts

the custom built equipment meant for the reliability testing of

thermal interface materials. Simultaneous non-Newtonian flow and

thermal conductivity characterization can be conducted using

this setup. Such a capability allows monitoring of flow response

as well as thermal conductivity change of TIMs subjected to

complex environmental conditions such as bake or thermal cycle.

This project has developed a test procedure to simultaneously

characterize thermal and non-Newtonian flow behavior of

polymeric thermal interface materials (TIMs). Also, reliability

characterization of representative polymeric TIMs using the

developed test procedure after exposure to high temperature bake

as well as thermal cycling of the materials. The picture depicts

the custom built equipment meant for the reliability testing of

thermal interface materials. Simultaneous non-Newtonian flow and

thermal conductivity characterization can be conducted using

this setup. Such a capability allows monitoring of flow response

as well as thermal conductivity change of TIMs subjected to

complex environmental conditions such as bake or thermal cycle.

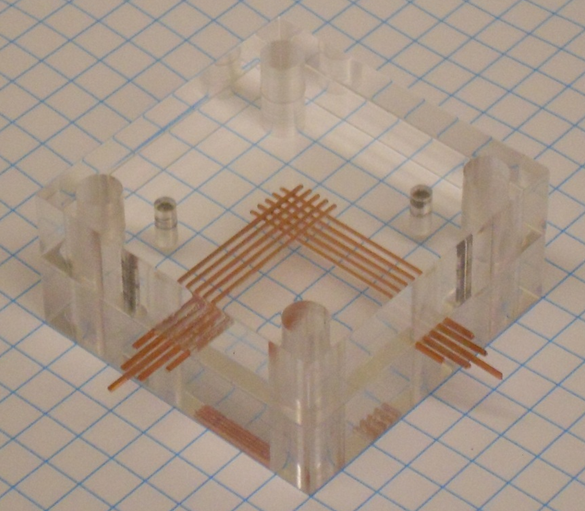

Impedance-Based Visualization of Voids in Thermal Interface Materials

This method provides a new way to test the effectiveness of the

thermal pastes used for keeping computer chips at appropriate

temperatures during operation.The project utilizes parallel

arrays of electrodes to form a square grid around the

interfacial gap. Capacitance measurements taken at the crossing

points of the grid allow for anomalies in the thermal interface

material to be detected. The figure shows the measuring device

using copper rods imbedded into two clear panels. Rods on one

panel criss-cross with the rods of the other panel.

Electrical measurements can determine whether there are bubbles

or cracks in the material between the panels.

This method provides a new way to test the effectiveness of the

thermal pastes used for keeping computer chips at appropriate

temperatures during operation.The project utilizes parallel

arrays of electrodes to form a square grid around the

interfacial gap. Capacitance measurements taken at the crossing

points of the grid allow for anomalies in the thermal interface

material to be detected. The figure shows the measuring device

using copper rods imbedded into two clear panels. Rods on one

panel criss-cross with the rods of the other panel.

Electrical measurements can determine whether there are bubbles

or cracks in the material between the panels.

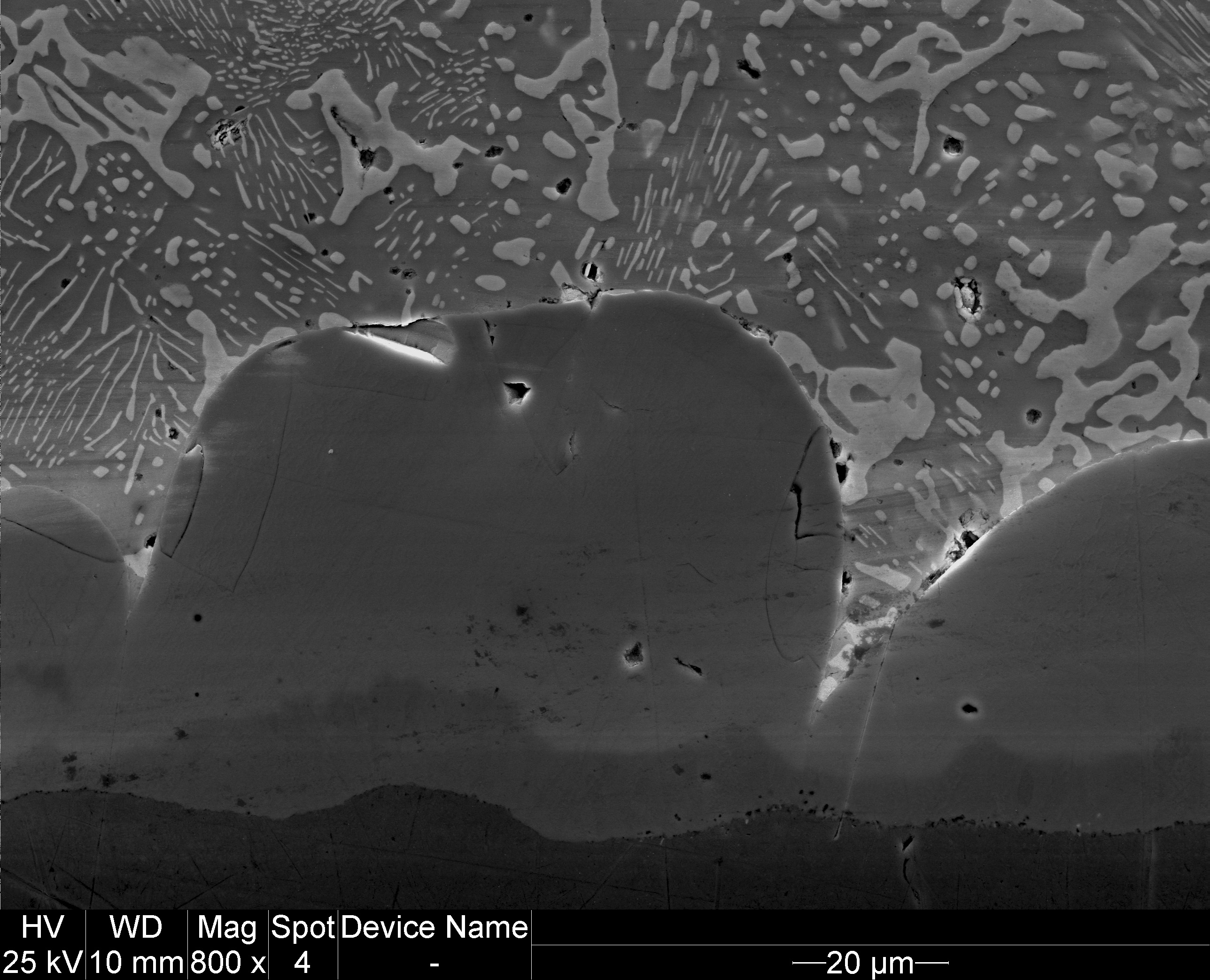

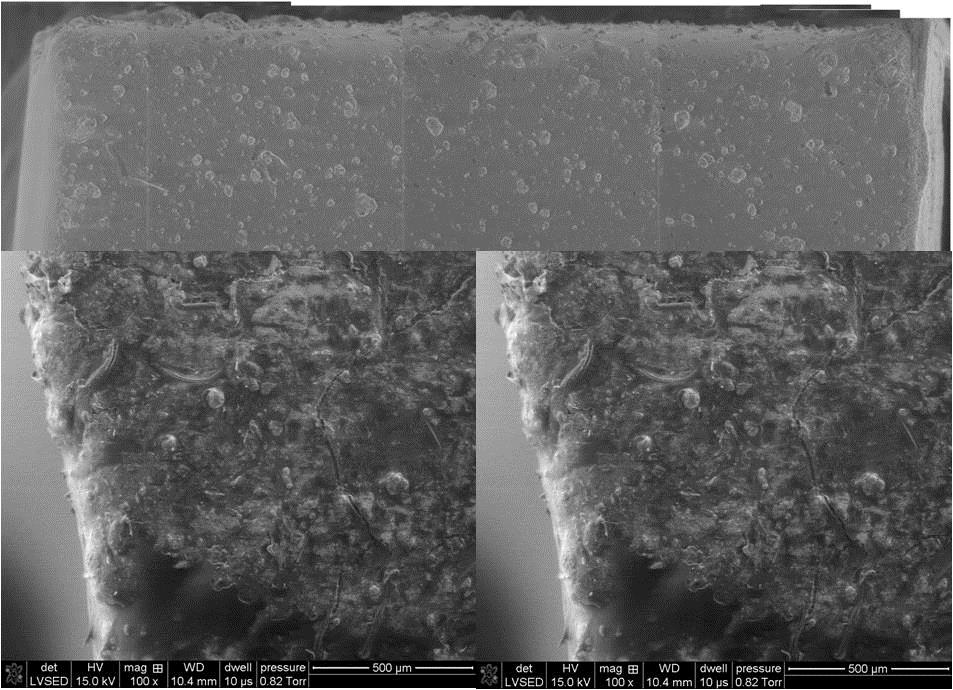

Performance and Reliability Impact of Compliant Thermal Interface Materials

Present work is aimed at the development of multiple cross-validated

test procedures to identify time-dependent viscoelastic behavior

of compliant TIMs and to correlate the mechanical response of

the materials to experimentally measured effective thermal

conductivity. Exhaustive viscoelastic characterization of the

Gap pad (compliant TIM) materials, and relating mechanical

cycling to measured thermal conductivity degradation of these

materials have been accomplished. This research also estimated

the stress transmitted to the solder joints through the gap pads

as a result of applied pressures during heatsink assembly. The

top figure is a cross-section of the chosen TIM as viewed under

environmental mode in a scanning electron microscope showing a

fiberglass pad on right side of the image. The lower two figures

are the chosen material also view.

Present work is aimed at the development of multiple cross-validated

test procedures to identify time-dependent viscoelastic behavior

of compliant TIMs and to correlate the mechanical response of

the materials to experimentally measured effective thermal

conductivity. Exhaustive viscoelastic characterization of the

Gap pad (compliant TIM) materials, and relating mechanical

cycling to measured thermal conductivity degradation of these

materials have been accomplished. This research also estimated

the stress transmitted to the solder joints through the gap pads

as a result of applied pressures during heatsink assembly. The

top figure is a cross-section of the chosen TIM as viewed under

environmental mode in a scanning electron microscope showing a

fiberglass pad on right side of the image. The lower two figures

are the chosen material also view.

Enhanced Thermal Contact Conductance Using Carbon Nanotube Interfaces

A tri-layer catalyst configuration has been developed for well

anchored and vertically oriented CNT arrays direct synthesized

on various substrates with plasma-enhanced chemical vapor

deposition and different catalyst metals. A test rig for thermal

contact resistance measurement (adapted from ASTM D 5470) has

been established in a high-vacuum environment, and temperature

measurements are accomplished with an infrared imaging system.

The figure above summarizes thermal interfacial resistance

results for a bare copper-silicon interface, a single-sided CNT

array, and a double-sided array. The results demonstrate that

the CNT arrays can exhibit resistances below 10 mm2K/W that are

comparable to the resistance of an ultra-thin soldered joint.

A tri-layer catalyst configuration has been developed for well

anchored and vertically oriented CNT arrays direct synthesized

on various substrates with plasma-enhanced chemical vapor

deposition and different catalyst metals. A test rig for thermal

contact resistance measurement (adapted from ASTM D 5470) has

been established in a high-vacuum environment, and temperature

measurements are accomplished with an infrared imaging system.

The figure above summarizes thermal interfacial resistance

results for a bare copper-silicon interface, a single-sided CNT

array, and a double-sided array. The results demonstrate that

the CNT arrays can exhibit resistances below 10 mm2K/W that are

comparable to the resistance of an ultra-thin soldered joint.

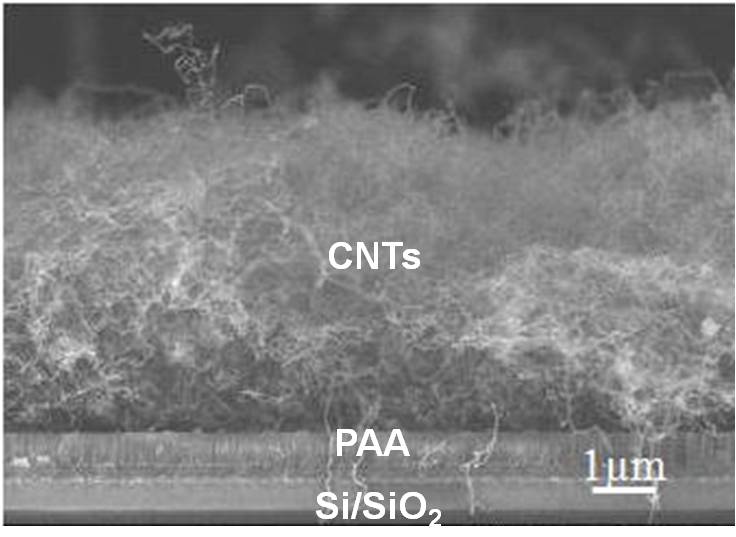

Thermal and Electrical Characterization of CNT Vias

CNTs with their unique combination of high current carrying capacity,

high thermal conductivity, mechanical integrity and electron

mean free paths of several microns may be ideal candidates for

next-generation interconnects. In this project, stable and dense

CNTs were grown from electrodeposited Pd in the bottom of porous

anodic alumina (PAA) pores, using buckypaper as a plasma screen.

CNT density was calculated to be up to 1.0x1010 cm-2,

and the minimum current density transported in CNT vias was

calculated to be 106 A/cm2, which is

comparable to or higher than Cu interconnects. Modifications to

CNTs by electron donating and electron withdrawing chemicals

(e.g., TTF and TCNE) have been made to improve the electrical

properties of CNT vias. The first figure shows a side view of

as-grown CNT's using Pd as catalysts.

CNTs with their unique combination of high current carrying capacity,

high thermal conductivity, mechanical integrity and electron

mean free paths of several microns may be ideal candidates for

next-generation interconnects. In this project, stable and dense

CNTs were grown from electrodeposited Pd in the bottom of porous

anodic alumina (PAA) pores, using buckypaper as a plasma screen.

CNT density was calculated to be up to 1.0x1010 cm-2,

and the minimum current density transported in CNT vias was

calculated to be 106 A/cm2, which is

comparable to or higher than Cu interconnects. Modifications to

CNTs by electron donating and electron withdrawing chemicals

(e.g., TTF and TCNE) have been made to improve the electrical

properties of CNT vias. The first figure shows a side view of

as-grown CNT's using Pd as catalysts.

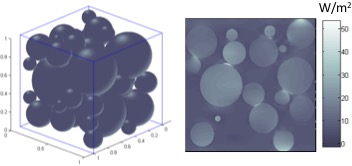

Validated Models for Particulate Thermal Interface Materials

Numerical modeling of realistic 3D microstructures (at high filler volume

loadings) considering inter-particle interactions was performed

using full-field meshless simulations and random particle

network simulations. The developed models are validated with

experiments on representative systems. The models can be

efficiently used to accurately predict the effect of varying: i)

the filler particle conductivity, ii) the base polymer matrix

conductivity, and iii) size-distribution and arrangement of the

filler particles on the composite thermal conductivity of TIMs.

Numerical modeling of realistic 3D microstructures (at high filler volume

loadings) considering inter-particle interactions was performed

using full-field meshless simulations and random particle

network simulations. The developed models are validated with

experiments on representative systems. The models can be

efficiently used to accurately predict the effect of varying: i)

the filler particle conductivity, ii) the base polymer matrix

conductivity, and iii) size-distribution and arrangement of the

filler particles on the composite thermal conductivity of TIMs.

Thermal Cycling Fatigue Effects on the Contact Resistance of Organic Interface Materials on Si

The development of an

accurate constitutive model of the effect of thermal cycling to

polymer interface layers will be necessary for the reliable

integration of organic materials into high performance packages.

Accurate measurements of heat flow are dependent upon knowing

and controlling the ambient operating conditions. Mapping the

development of interface defects is important for improving the

materials which aid in the removal of heat from electronic

packages. Finding and documenting the evolution of the defects

is dependent upon a full understanding of the thermal probes

response to changing environmental conditions. Changes in test

operating conditions can dominate changes to local interface

properties.