CTRC Breakthroughs

Thin-Film Transport, Wicks and Heat Pipes

Research Topics

Microscale Transport and Microchannels

Electrically Actuated Microscale Flows

Thin-Film Transport, Wicks and Heat Pipes

Novel Air and Impingement Cooling Approaches

Surface and Interface Engineering

Thermal Materials R&D

Thermal Interfaces

Small-Scale Refrigeration

Exploratory and Novel Concepts

Renewable and Sustainable Energy

Power Dissipation Limits in Low-Profile Heat Sinks with Embedded Vapor Chamber Heat Spreaders

The maximum heat dissipation capability of low-profile heat sinks can be improved by using vapor chamber heat spreaders in the heat sink base. As emerging applications push the limits of power density, nucleate boiling can occur within the vapor chamber. Our work has enabled the design of heat sinks having embedded vapor chambers for high power density applications by understanding and predicting the hydrodynamics and heat transfer associated with boiling in the evaporator wick. The modeling tools developed as part of the work allow for design of the vapor chamber and overall heat sink architecture, ultimately predicting the limits of power dissipation in these architectures.

The maximum heat dissipation capability of low-profile heat sinks can be improved by using vapor chamber heat spreaders in the heat sink base. As emerging applications push the limits of power density, nucleate boiling can occur within the vapor chamber. Our work has enabled the design of heat sinks having embedded vapor chambers for high power density applications by understanding and predicting the hydrodynamics and heat transfer associated with boiling in the evaporator wick. The modeling tools developed as part of the work allow for design of the vapor chamber and overall heat sink architecture, ultimately predicting the limits of power dissipation in these architectures.

Analysis of Thin Vapor Chamber for Thermal Management under Transient Heat Loading

Hot spot mitigation in electronic devices under dynamic scenarios is a critical thermal challenge. While vapor chambers have long been an effective method to deal with thermal hotspots, the predominant design approaches have been founded on a core assumption of steady state operation; there is urgent need to overhaul these approaches, and the understanding of transient vapor chamber operation, so as to allow design for practical scenarios. In previous work in the CTRC, a novel analytical model was developed that enables rapid assessment of transient vapor chamber behavior in a variety of dynamic loading scenarios. This model was used to reveal the mechanisms governing the transient performance of a vapor chamber. Based on this new understanding, a refreshed set of design guidelines have been proposed based on the thermal performance of vapor chamber under transient condition. The design procedure yields the working fluid and vapor chamber dimensions that minimize the hotspot temperature in response to a transient step heat input. Furthermore, to facilitate immediate adoption of the understanding derived from the model, closed-form analytical expressions for the effective anisotropic thermal conductance have been derived. These expressions can be plugged into any transient conduction solver as material properties to accurately simulate the thermal response of a vapor chamber.

Hot spot mitigation in electronic devices under dynamic scenarios is a critical thermal challenge. While vapor chambers have long been an effective method to deal with thermal hotspots, the predominant design approaches have been founded on a core assumption of steady state operation; there is urgent need to overhaul these approaches, and the understanding of transient vapor chamber operation, so as to allow design for practical scenarios. In previous work in the CTRC, a novel analytical model was developed that enables rapid assessment of transient vapor chamber behavior in a variety of dynamic loading scenarios. This model was used to reveal the mechanisms governing the transient performance of a vapor chamber. Based on this new understanding, a refreshed set of design guidelines have been proposed based on the thermal performance of vapor chamber under transient condition. The design procedure yields the working fluid and vapor chamber dimensions that minimize the hotspot temperature in response to a transient step heat input. Furthermore, to facilitate immediate adoption of the understanding derived from the model, closed-form analytical expressions for the effective anisotropic thermal conductance have been derived. These expressions can be plugged into any transient conduction solver as material properties to accurately simulate the thermal response of a vapor chamber.

Transient Analysis of Thin Vapor Chambers for Mobile Thermal Management

Highly effective heat spreading is needed in portable electronic devices to mitigate transient hotspots. While thin vapor chambers provide extreme heat spreading performance potential, their transient thermal behavior in response to dynamic heating conditions was previously not well understood. A first-of-its-kind analytical model was developed that simulates the transient thermal behavior of thin vapor chambers at extremely low computational cost, without compromise in accuracy or functionality. The model revealed the primary mechanisms that govern the transient behavior of vapor chambers; these newly identified mechanisms were verified experimentally. The validated model, which was used to compare the relative performance of a vapor chamber versus a solid heat spreader over a range of operating conditions, will allow engineers to make an informed selection of heat spreader type for transient applications

Thin Heat Pipes for Low Power Applications

Using analytical and numerical models, the performance of thin heat pipes have been evaluated and compared to that of a baseline copper heat spreader. The results of this study will generate comprehensive guidelines for the range of geometries and boundary conditions under which ultra-thin heat pipes may provide a comparative performance benefit against the current solid heat spreaders used in industry. Prior to tackling practical manufacturing challenges (namely, wick structure, fluid charging, mechanical robustness) the study assess the theoretical limits and design objectives.

Characterization of Composite Heat Spreaders

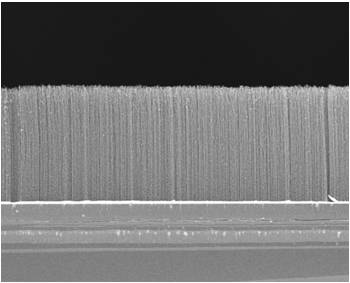

The

characterization of composite heat spreaders using the 3-omega

method has been used widely to provide accurate thermal

conductivity measurement of materials in the past several

decades. The total thermal resistance of a cooling package can

be reduced by replacing traditional Al/Cu heat spreaders with

suitable low cost new materials. Furthermore, carbon nanotubes (CNTs)

are synthesized on heat spreaders to improve heat transfer at

interface. The results indicate that, using an Al/Ti/Fe

tri-layer catalyst, a high-density CNT array can be directly and

firmly bonded to heat spreader surface. The figure shows CNT

array synthesis on silicon substrate.

The

characterization of composite heat spreaders using the 3-omega

method has been used widely to provide accurate thermal

conductivity measurement of materials in the past several

decades. The total thermal resistance of a cooling package can

be reduced by replacing traditional Al/Cu heat spreaders with

suitable low cost new materials. Furthermore, carbon nanotubes (CNTs)

are synthesized on heat spreaders to improve heat transfer at

interface. The results indicate that, using an Al/Ti/Fe

tri-layer catalyst, a high-density CNT array can be directly and

firmly bonded to heat spreader surface. The figure shows CNT

array synthesis on silicon substrate.

Thin Film Evaporation

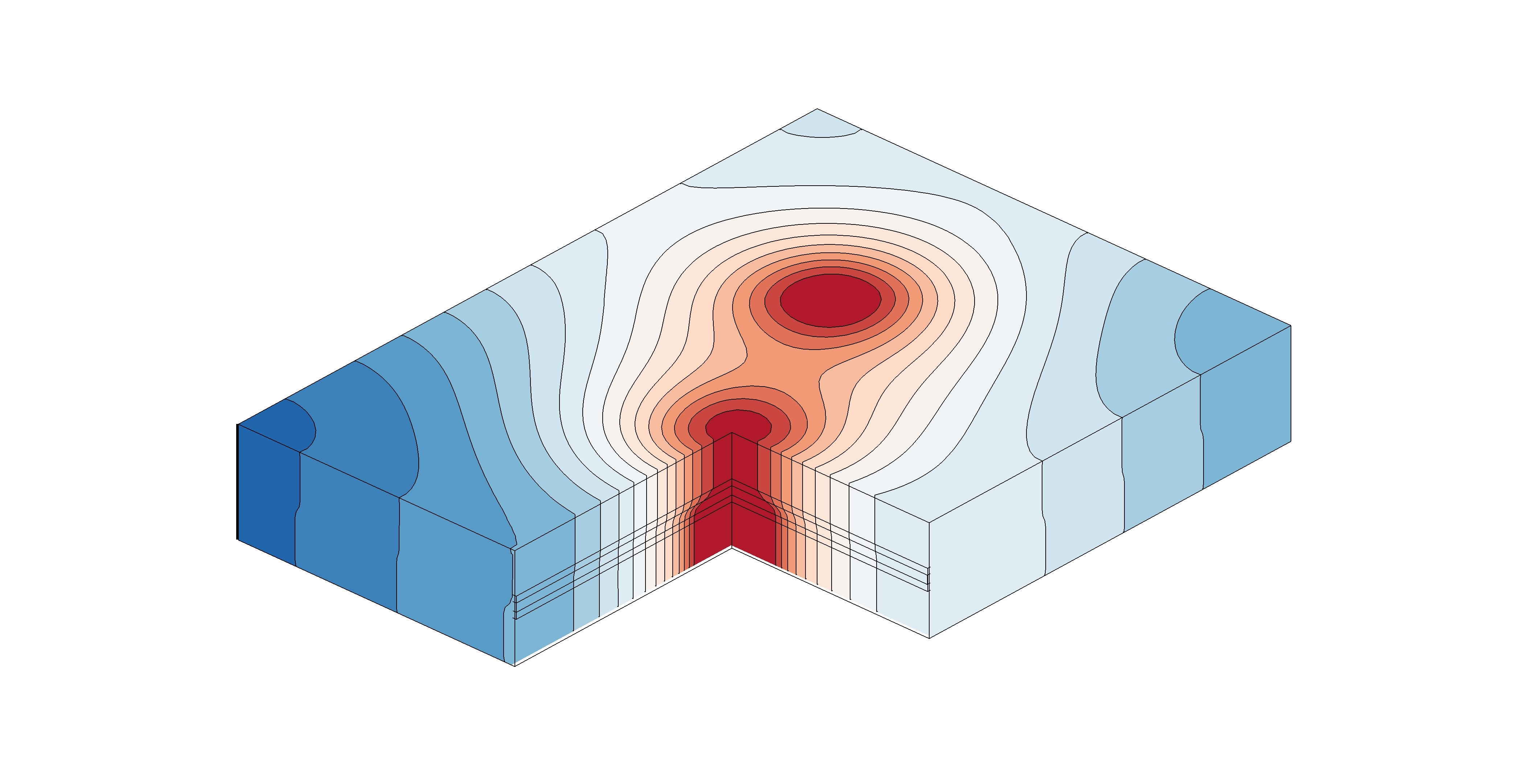

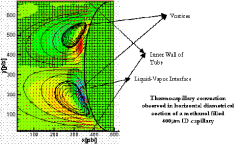

Evaporation,

taking place at the very thin solid-liquid-vapor junction, is

claimed to be the dominant mode of heat transfer in a

liquid-vapor phase change process. Micro-PIV experiments are

being performed to study the flow pattern near the evaporating

meniscus. The differential evaporation sets up a temperature

gradient between the corners and the center of meniscus which

generates the thermocapillary convection seen in the form of two

counter-rotating vortices. This strong convection is expected to

increase the total heat transfer by providing better mixing of

the fluid.

Evaporation,

taking place at the very thin solid-liquid-vapor junction, is

claimed to be the dominant mode of heat transfer in a

liquid-vapor phase change process. Micro-PIV experiments are

being performed to study the flow pattern near the evaporating

meniscus. The differential evaporation sets up a temperature

gradient between the corners and the center of meniscus which

generates the thermocapillary convection seen in the form of two

counter-rotating vortices. This strong convection is expected to

increase the total heat transfer by providing better mixing of

the fluid.

Experimental Investigation of the Transport Properties of Wicks

Heat

pipes are commonly used in electronics cooling applications due

to their ability to move high amounts of heat over reasonable

distances with only a small drop in temperature. Porous wick

structures imbedded inside heat pipes provide the interfacial

tension necessary to drive the working fluid. Improved

measurements and observation of transport processes are also

aiding in the design of miniaturized heat pipes. Two dedicated

heat pipe wick-testing facilities have been established. One

measures mass transport in a variety of flat wick structures,

including sintered copper and aluminum grooved wicks. The second

facility is an instrumented thermosyphon test bed to measure

conductivity values for wick structures under varying degrees of

wick saturation.

Heat

pipes are commonly used in electronics cooling applications due

to their ability to move high amounts of heat over reasonable

distances with only a small drop in temperature. Porous wick

structures imbedded inside heat pipes provide the interfacial

tension necessary to drive the working fluid. Improved

measurements and observation of transport processes are also

aiding in the design of miniaturized heat pipes. Two dedicated

heat pipe wick-testing facilities have been established. One

measures mass transport in a variety of flat wick structures,

including sintered copper and aluminum grooved wicks. The second

facility is an instrumented thermosyphon test bed to measure

conductivity values for wick structures under varying degrees of

wick saturation.