Capabilities and Facilities

Purdue University has a pre-eminent program in Mechanical Engineering, supported by equally strong programs in Electrical, Chemical, Aeronautics and Materials Engineering across the College of Engineering. Built on a long tradition of excellence, the School of Mechanical Engineering has become synonymous with accomplishment and leadership in engineering education and engineering research. Over 75 faculty are dedicated to educating over 2000 undergraduate and graduate students, and to maintaining and developing world-class research programs.The curriculum provides a solid foundation in basic engineering principles while at the same time expanding student reasoning, communication and problem-solving skills. The School offers a comprehensive program in mechanical engineering and is organized into the following areas: Acoustics and Noise Control; Bioengineering; Computational Engineering; Combustion; Design; Fluid Mechanics and Propulsion; Heat Transfer; Heating, Ventilation, Air Conditioning and Refrigeration; Manufacturing and Materials Processing; Mechanics and Vibration; Nanotechnology; Robotics; Solid Mechanics; and Systems Measurement and Control.

Excellent, state-of-the-art facilities and laboratories are available for the conduct of projects for the Center. As exemplified by the $34.5 million state-of-the-art Roger B. Gatewood Wing addition to the Mechanical Engineering building, Purdue University is investing strongly in new facilities that will help in further growth of the Center. The School's extensive facilities include two major satellite research laboratories, the Ray W. Herrick Laboratories and the Zucrow Laboratories, and over 30 additional instructional and research laboratories. In addition, faculty have access to the unique interdisciplinary facilities, cutting-edge equipment and shared spaces of Discovery Park, including the Birck Nanotechnology Center and FlexLab. The School is supported by a comprehensive computing environment, libraries and technical services.

The Cooling Technologies Research Center is well poised to be the leader in the field of cooling technologies. Many of its attributes make it unique in the country, including its strong focus on experimental work complemented by computational analysis; its diversity of member companies allowing for cross-fertilization of ideas between different product lines; its strong and continual interaction with industry members; and its large range of experimental facilities available within and outside the School. The Center also has access to an excellent graduate student applicant pool.

The Birck Nanotechnology Center (BNC) is an interdisciplinary research unit that provides infrastructure for 160 affiliated faculty members and their research groups from 36 academic units at Purdue. The 186,000 sq ft. facility includes a 25,000 sq. ft. ISO Class 3-4-5 (Class 1-10-100) nanofabrication cleanroom – the Scifres Nanofabrication Laboratory – that includes a 2,500 sq. ft. ISO Class 6 (Class 1000) pharmaceutical-grade biomolecular cleanroom

Founded in 1957, Herrick Labs supports world-class Mechanical Engineering research for students, faculty, and industry. Among the facilities available in our 83,000 square feet of space are HVAC and indoor air quality labs; advanced engine test cells; acoustics, noise, and vibration testing; and unique perception-based engineering labs. The lab hosts research in: high performance buildings; acoustics, vibrations & dynamics, electromechanical systems, and human response to engineered systems.

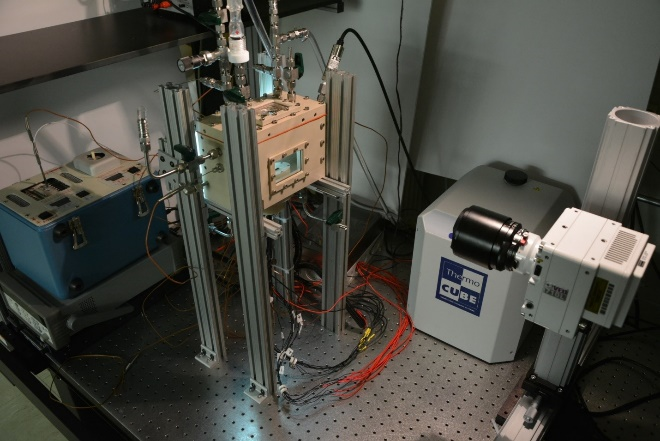

Electronics Cooling and Thermal Microsystems Laboratory

The Electronics Cooling and Thermal Microsystems Laboratory at Purdue University is led by Dr. Justin Weibel investigates methodologies for prediction and control of heat transport to enhance the performance and efficiency of thermal management technologies, energy transfer processes, and other thermal systems. The laboratory contain an array of experimental test equipment that enables the development of cutting-edge cooling technologies, as well as fundamental investigation of the underlying thermal and fluid transport processes.

Sustainable Energy and Nanoscale Transport Laboratory

Sustainable energy, thermal management, and energy storage are amon the greatest challenges facing the society. Solutions to these challenges rely on extraordinarily fundamental and innovative approaches. The Sustainable Energy and Nanoscale Transport Lab is developing innovative energy solutions with emerging tools including nanotechnology, machine learning, large scale computation, and additive manufacturing.

Marconnet Thermal & Energy Converstion (MTEC) Lab

Research in the MTEC Lab integrates metrology and analysis of underlying transport mechanisms with design and development of nanostructured materials. Nanostructuring leads to unique material properties and combinations of properties not naturally available in bulk materials. Nanostructured materials offer the possibility of thermal conductivity extremes. Electron-crystal, phonon-glass materials are of interest for thermoelectric applications, while thermally-conductive, mechanically-compliant materials are sought for electronics packaging.

Laboratory of Plasmon-Assisted Nanomanufacturing

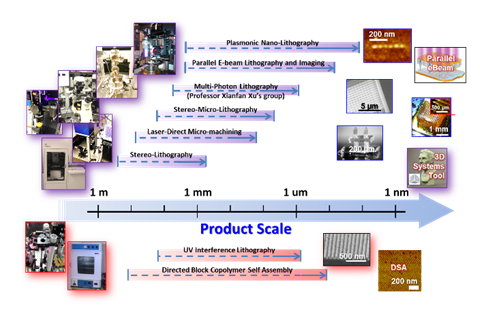

Led by Dr. Liang Pan, the lab focuses on the fundamental of micro- and nano-scale science and engineering, aiming on making breakthroughs of novel alternative approaches to keep current trend of continuous size scaling down for emerging nanotechnology by circumventing fundamental physic limits, with emphasis on the applications of lithography, imaging and metrology for manufacturing; data storage, communication and computation for information technology; and nanoscale energy conversion, transfer and storage for new alternative energy.

Hierarchical Design and Characterization Lab

The research in the Hierarchical Design And Characterization (HiDAC) lab at Purdue University is broadly concerned with computational and experimental solid mechanics as well as CAD with applications to characterizing failure of microelectronic components and assemblies. The specific focus within these areas is on isogeometric analysis, multiphysics modeling of moving interfaces and boundaries including fracture propagation, shape and topological optimal design as well as in thermal conduction in particulate composites.

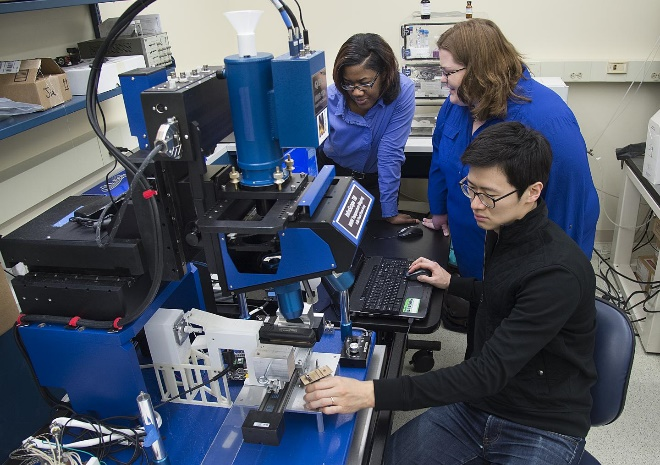

Particle, Powder, and Compact Characterization Laboratory

Purdue University has a dedicated 3000 ft2 facility located in FLEX 3001 for powder, particle and compact characterization. The lab, led by Dr. Carl Wassgren comprises equipment for measurement of powder physical properties such size, shape, density and flow. In addition, the lab also houses equipment to prepare powder compacts and test their mechanical properties and study their microstructure in a non-destructive manner.

School of Materials Engineering Lab Facilities

A variety of characterization tools are available ro researchers in the School of Materials Engineering lab facilities in the Armstrong Hall of Engineering for material design and characterization of polymers and nanocomposites.