CTRC Breakthroughs

Surface and Interface Engineering

Research Topics

Microscale Transport and Microchannels

Electrically Actuated Microscale Flows

Thin-Film Transport, Wicks and Heat Pipes

Novel Air and Impingement Cooling Approaches

Surface and Interface Engineering

Thermal Materials R&D

Thermal Interfaces

Small-Scale Refrigeration

Exploratory and Novel Concepts

Renewable and Sustainable Energy

Surface Treatment for Boiling Heat Transfer Enhancement

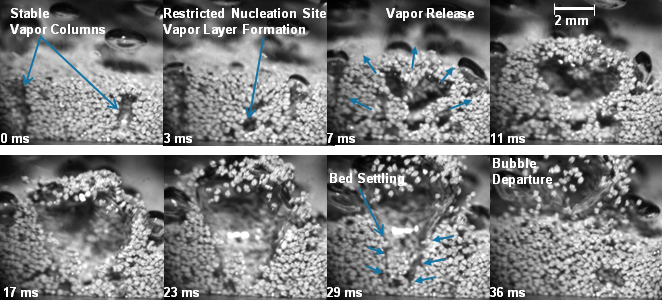

The present study proposes a free particle technique to provide the

same active nucleation sites as for sintered particles, but with a

deformable particle layer to reduce the vapor pressure drop during

boiling (increases performance). A pool boiling test facility was

constructed to allow high-speed visualization of boiling from a bed

of free particles. Three free particle sizes were tested to

investigate boiling characteristics and heat transfer enhancement

over polished surface. The image shows the passive deformation of

the free particle layer to release vapor bubble during pool boiling.

A 32% reduction in surface superheat up to the same critical heat

flux as measured for the polished surface is measured.

The present study proposes a free particle technique to provide the

same active nucleation sites as for sintered particles, but with a

deformable particle layer to reduce the vapor pressure drop during

boiling (increases performance). A pool boiling test facility was

constructed to allow high-speed visualization of boiling from a bed

of free particles. Three free particle sizes were tested to

investigate boiling characteristics and heat transfer enhancement

over polished surface. The image shows the passive deformation of

the free particle layer to release vapor bubble during pool boiling.

A 32% reduction in surface superheat up to the same critical heat

flux as measured for the polished surface is measured.

Acoustically Enhanced Heat Transfer

The aim of the project is the enhancement of heat transfer with an

acoustic sound field with, ideally, a smaller pressure drop in

comparison to other surface enhancements. This project involved

experimental investigation of acoustically enhancing the heat

transfer from a fluid flow to the solid wall of a plain tube and

determining the influence of an acoustic field on the rate of heat

transfer. A prototype test stand had been constructed in which air

was the working fluid. The figure plots dimensionless heat transfer

enhancement (Q/Q0) against

the frequency at various sound levels (top) showing that heat

transfer can be enhanced with an acoustic field by up to 30%.

Differential pressure inside of the test section plotted against the

frequency (below) shows that with a particular frequency, the

differential pressure is negative.

The aim of the project is the enhancement of heat transfer with an

acoustic sound field with, ideally, a smaller pressure drop in

comparison to other surface enhancements. This project involved

experimental investigation of acoustically enhancing the heat

transfer from a fluid flow to the solid wall of a plain tube and

determining the influence of an acoustic field on the rate of heat

transfer. A prototype test stand had been constructed in which air

was the working fluid. The figure plots dimensionless heat transfer

enhancement (Q/Q0) against

the frequency at various sound levels (top) showing that heat

transfer can be enhanced with an acoustic field by up to 30%.

Differential pressure inside of the test section plotted against the

frequency (below) shows that with a particular frequency, the

differential pressure is negative.