CTRC Breakthroughs

Small Scale Refrigeration

Research Topics

Microscale Transport and Microchannels

Electrically Actuated Microscale Flows

Thin-Film Transport, Wicks and Heat Pipes

Novel Air and Impingement Cooling Approaches

Surface and Interface Engineering

Thermal Materials R&D

Thermal Interfaces

Small-Scale Refrigeration

Exploratory and Novel Concepts

Renewable and Sustainable Energy

When choosing the coolant for a specific application, the material

compatibility, toxicity, corrosion properties have to be considered

in addition to their thermal performance. This project focused

on answering these system considerations. As a part of the project,

an extensive liquid-loop coolant database was developed with 56

single-phase and two-phase fluids that can be used in electronics

cooling. In addition, a simulation tool was developed to

predict the coolant performance in single-phase and two-phase flow

microchannels.

When choosing the coolant for a specific application, the material

compatibility, toxicity, corrosion properties have to be considered

in addition to their thermal performance. This project focused

on answering these system considerations. As a part of the project,

an extensive liquid-loop coolant database was developed with 56

single-phase and two-phase fluids that can be used in electronics

cooling. In addition, a simulation tool was developed to

predict the coolant performance in single-phase and two-phase flow

microchannels.

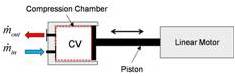

Miniature Scale Linear Compressor for Electronics Cooling

A linear compressor is considered a promising new development in

component technology due to the potential for high performance and

high scalability. This work has developed a comprehensive model of a

linear compressor based on first principals. This model has shown

good agreement when compared with experimental data and can be used

for future development of linear compressor technology. The figure

is a schematic of a linear compressor.

A linear compressor is considered a promising new development in

component technology due to the potential for high performance and

high scalability. This work has developed a comprehensive model of a

linear compressor based on first principals. This model has shown

good agreement when compared with experimental data and can be used

for future development of linear compressor technology. The figure

is a schematic of a linear compressor.

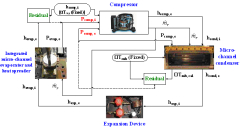

Miniature-Scale Refrigeration System (MSRS) for Electronics Cooling

The

simulation model for the refrigeration system is based on

thermodynamics, heat transfer and fluid mechanics concepts applied

to miniature scale components of a micro vapor compression system,

including the compressor, mini-channel condenser, expansion device,

and integrated cold plate evaporator and heat spreader. The system

model shown in the figure simulates a refrigeration system with an

active expansion device. Hence, only two parameters, suction and

discharge pressures, need to be estimated to completely define the

operating conditions and performance of the vapor compression

system. The model predicts all state points of the

micro-refrigeration system and the power consumption and the

efficiency of the cooling system.

The

simulation model for the refrigeration system is based on

thermodynamics, heat transfer and fluid mechanics concepts applied

to miniature scale components of a micro vapor compression system,

including the compressor, mini-channel condenser, expansion device,

and integrated cold plate evaporator and heat spreader. The system

model shown in the figure simulates a refrigeration system with an

active expansion device. Hence, only two parameters, suction and

discharge pressures, need to be estimated to completely define the

operating conditions and performance of the vapor compression

system. The model predicts all state points of the

micro-refrigeration system and the power consumption and the

efficiency of the cooling system.

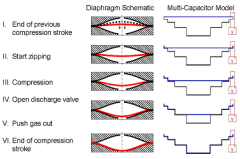

Miniature-Scale Daiphragm Compressor for Electronics Cooling

Results

from the compressor model indicate that an Miniature Scale Diaphragm

Compressor (MSDC) has excellent thermodynamic performance and good

potential for miniaturization and integration with

micro-refrigeration systems to cool high-heat-dissipation

microprocessors. The diaphragm compressor consists mainly of two

contoured conductive planes that serve as electrodes. These are

separated by dielectric insulation layers and a gas/refrigerant gap.

If a voltage differential is applied between the electrodes, the

electrostatic force deforms the diaphragm and pulls it towards the

electrode on the chamber wall. Suction and discharge flapper

mini-valves control the refrigerant flow in and out of the

compressor chamber. Target parameters for the diaphragm compressor

include a heat removal of 200 W, pressure head of 750 kPa, pressure

ratio of 2, and flow rate of 3000 ml/min, accomplished with a

diaphragm compressor of 80 mm in diameter and 20 mm in height.

Results

from the compressor model indicate that an Miniature Scale Diaphragm

Compressor (MSDC) has excellent thermodynamic performance and good

potential for miniaturization and integration with

micro-refrigeration systems to cool high-heat-dissipation

microprocessors. The diaphragm compressor consists mainly of two

contoured conductive planes that serve as electrodes. These are

separated by dielectric insulation layers and a gas/refrigerant gap.

If a voltage differential is applied between the electrodes, the

electrostatic force deforms the diaphragm and pulls it towards the

electrode on the chamber wall. Suction and discharge flapper

mini-valves control the refrigerant flow in and out of the

compressor chamber. Target parameters for the diaphragm compressor

include a heat removal of 200 W, pressure head of 750 kPa, pressure

ratio of 2, and flow rate of 3000 ml/min, accomplished with a

diaphragm compressor of 80 mm in diameter and 20 mm in height.