Wave Rotor Combustor Rig Tests Initiated at Purdue University

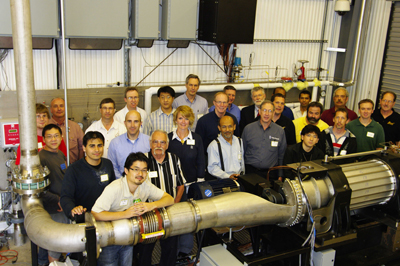

On May 8 2009, the test facility for the Wave Rotor Combustor Rig (WRCR) was opened at the Maurice Zucrow Laboratories in the Annex of the High Pressure Laboratory (HPL). The rig is devoted to basic research on constant volume combustion (CVC) integrated into a dynamic pressure exchanger system. The event was the result of a multi-year partnership with Indiana University-Purdue University at Indianapolis (IUPUI), Purdue University and Rolls-Royce North American Technology Inc. (LibertyWorks®). More than a dozen graduate students and post docs at IUPUI and Purdue have contributed over the past 10 years to various aspects of the modeling and design. Also extensive infrastructure improvements at Purdue University have aided the effort, both contributions coming partially through support by the Indiana 21st Century Research and Technology Fund.

On May 8 2009, the test facility for the Wave Rotor Combustor Rig (WRCR) was opened at the Maurice Zucrow Laboratories in the Annex of the High Pressure Laboratory (HPL). The rig is devoted to basic research on constant volume combustion (CVC) integrated into a dynamic pressure exchanger system. The event was the result of a multi-year partnership with Indiana University-Purdue University at Indianapolis (IUPUI), Purdue University and Rolls-Royce North American Technology Inc. (LibertyWorks®). More than a dozen graduate students and post docs at IUPUI and Purdue have contributed over the past 10 years to various aspects of the modeling and design. Also extensive infrastructure improvements at Purdue University have aided the effort, both contributions coming partially through support by the Indiana 21st Century Research and Technology Fund.

A series of initial test operation has been conducted to investigate leakage characteristics, the torch igniter and the fuel injection system in the three weeks in May 2009. Rolls-Royce Corporation Method Specialist Dr. Masa Shimo was on-site to supervise the test operation. Dr. Philip Snyder is lead engineer for CVC within Rolls-Royce and Dr. M. Razi Nalim directs the wave rotor modeling and design effort at IUPUI. Dr. Shimo was a Purdue Aeronautics and Astronautics Engineering (AAE) graduate in 2006 and a former Purdue senior research scientist while conducting pulsed detonation combustor research at HPL under the direction of Dr. Stephen Heister.

"We obtained valuable data from the initial test operation," says Dr. Shimo, who adds that the test operations did not have any major issues to provide requested test operating conditions, thanks to the Purdue facility installation team led by Scott Meyer, Senior Research Engineer and Yu Matsutomi, AAE Graduate Student. "We spun the rotor up to 2150 rpm with 8 lbm/s of air and continuously lighted the torch igniter without any issues." The torch igniter is the primary ignition system of the WRCR to initiate deflagration combustion in the propane-air mixture provided by the fuel injection systems. "The extensive on-rotor dynamic test data has helped us validate out prediction methods and determine the next steps."

"The wave rotor concept itself is a classic idea which was originally suggested in the 1940s and the CVC concept for the gas turbine application is as old as in the early 1920s when turbine inlet temperature was two or three times lower as the current level due to temperature limitation of turbine blade material." Dr. Shimo acknowledges the concept is challenging, but features of the highly flexible rig are available to demonstrate that the wave rotor CVC approach is viable for development into a commercial engine product. The two concepts are now being combined to deliver a step increase in turbine engine performance. The next phase of the WRCR test operation is currently under consideration at LibertyWorks.