TiCrMn Hydride Project

Overview

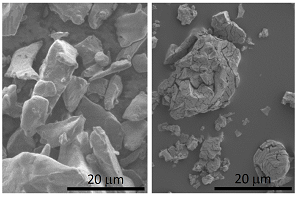

SEM images of TiCrMn (a) after cycling and (b) before cycling

Phase field simulation of hydride growth

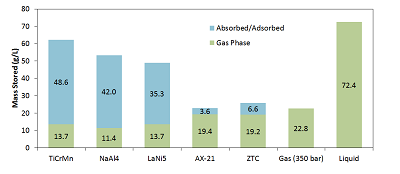

Automotive hydrogen storage systems require a significant increase in the volumetric storage density of hydrogen to provide the necessary range for ordinary use. Solid storage can provide significant increases in volumetric storage capacity of hydrogen at ambient temperatures. In this multi-year collaboration with General Motors, we used TiCrMn as a representative material to investigate:

- Thermal transport restrictions in activated metal hydride powder beds

- Additives to enhance thermal conductivity

- Interactions between thermal and kinetic limitations during tank fueling cycle

- Model development of hydride bed transport phenomena

- Heat exchanger design for metal hydride systems

|

|

|

|

|

||

Capabilities

- High pressure (410 bar) vehicle-scale hydrogen fueling system

- Multi-kilogram scale metal hydride test facility

- Research expertise in hydrogen storage materials of a variety of types

Accomplishments

- Achieved hydrogen refueling time under the 5 minute DOE target with TiCrMn

- Developed FLUENT transport model (video) of metal hydride heat exchanger validated by experimental data

- Developed fundamental phase field model for description of mass transport in metal hydrides

- Demonstrated metal hydride tank performance against standard hydrogen vehicle driving cycle

- Designed patented coil heat-exchanger for metal hydride tanks

- Established capabilities for safe handling of pyrophoric materials (activation)

Multimedia

|

Description: TiCrMn tray heat exchanger, experimental results - hydriding and dehydriding Sponsor: General Motors | |

|

Description: TiCrMn tray heat exchanger, large pocket experimental results - hydriding and dehydriding Sponsor: General Motors | |

|

Description: TiCrMn tray heat exchanger, all trays experimental results - hydriding and dehydriding Sponsor: General Motors |

People

Program Manager

Dr. Darsh Kumar, General Motors

PIs

Researchers

, Ph.D. Student (graduated)

, Ph.D. Student (graduated)

, M.S. Student (graduated)

, M.S. Student (graduated)

, Undergraduate Student (graduated)