Magnesium Hydride Project

Overview

The overall objective of the proposed program is to develop a magnesium hydride based storage system with rapid kinetics and high storage capacity. The Purdue effort is dedicated to the characterization of the heat and mass transport processes in a representative packed hydride bed.

Magnesium hydride offers the potential of up to 7.6 wt.% hydrogen, one of the highest capacities of any metal hydride. However, the high stability of the hydride phase necessitates operation at elevated temperatures and the addition of catalysts, both of which reduce the overall hydrogen storage density. Researchers at ITRI have developed catalysts that can improve kinetics considerably, which will be combined with the thermal analysis done by Purdue to produce a feasible system.

Material Processing

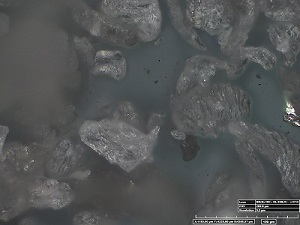

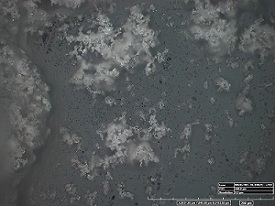

Mechanical and thermochemical activation of the as-received magnesium hydride results in visible particle degradation. The images below show a considerable particle size decrease after ball-milling in a Resodyne compared with the as-received powder shown above.

|

|

|

Thermal Conductivity and Diffusivity Measurements

In-Situ TPS System

In-Situ TPS System

Measurement of magnesium hydride thermal properties under applicable conditions requires an experimental apparatus capable of handling temperatures above 670 K and moderate pressures (10 to 30 bar). We modified our existing TPS system to allow testing at these conditions. Key features of the modified system are:

- Use of a Mica sensing element capable of handling up to 1270 K

- Integration of the sensing element into a high-temperature compatible pressure vessel with metal seals

These conditions allowed us to measure both Mg and MgH2 thermal properties over temperatures from ambient to 670 K and pressures from vacuum to 30 bar in hydrogen, helium, and argon.

Thermal Contact Resistance Measurements

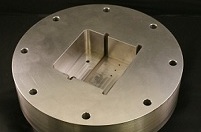

Thermal contact resistance in a metal hydride reactor between the hydride and its container can have a significant effect on performance, but is a largely unquantified variable. To better understand this phenomena, we designed an optically accessible magnesium hydride reactor with the necessary instrumentation to measure the thermal contact resistance under different conditions. Key features of the design include:

- An integrated cooling plate to induce temperature gradients across the powder-wall boundary

- Evenly spaced thermocouples and an IR camera with a zinc selenide window to measure temperature gradients at the powder-wall interface

- A movable spring-loaded plate to measure powder expansion force during the hydriding reaction, measured through a sapphire window

|

|

|

|

Accomplishments

- Measured reaction-dependent effective thermal properties of MgH2-based materials

- Developed a temperature conditioned optically accessible microscale hydride reactor for direct visualization of the hydriding of MgH2

People

Program Manager

PI

Researchers

, Postdoc (Now at Sandia) , M.S. student, Purdue University , M.S. student, Purdue University