Lab Capabilities

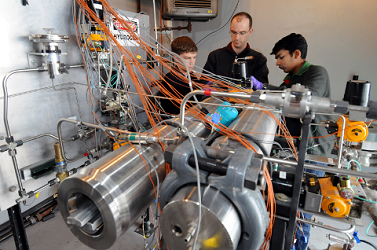

- 620 L (22 cubic feet) of 410 bar (6000 psi) hydrogen storage

- Dual-stage pneumatic compressor

- Sized for propulsion and automotive application

- Remotely controlled to supply multiple research areas

- Six-port MBraun LabMaster glovebox with instrumentation feedthroughs

- Argon atmosphere maintained at less than 0.1 ppm water vapor and less than 0.1 ppm oxygen

- 1.5 cubic meters of working space

- Oversized antechamber for transfer of kilogram-scale hydride systems

- Multiple kilogram scale hydrogen storage systems

- System rated to 410 bar; remotely controlled

- Storage systems designed and successfully tested to fill hydrogen within 5 minutes

- Experiments support analytical and CFD hydride bed modeling

- Characterize hydrogen storage materials at pressure and temperatures expected for vehicle operation

- Study metal hydrides (TiCrMn and LaNi5) and high pressure adsorbents

- Operating conditions of vacuum to 700 bar, 230 to 350 K

- PID temperature control using thermoelectric coolers

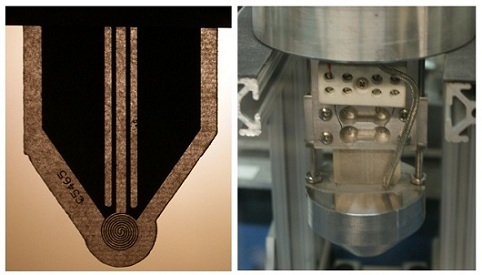

- Measure thermal conductivity, thermal diffusivity, and volumetric specific heat of powders, pellets, and composite materials via transient heating methods (plane source and hot wire methods)

- Knowledge of these properties is critical for the utilization of solid-state materials for hydrogen storage

- Operates in ambient environment, Argon environment, or sealed pressure vessel

- Pressure vessel operation from vacuum to 630 bar and room temperature to 670 K

- Automatic 3D image reconstruction

- Topographical mapping down to micro-meter scales

- Precise length and area measurements at micro-meter to millimeter scales

- Developed Purdue Metal Hydride Toolbox (PMHT) of properties and sub-models of over 300 hydrides

- Made PMHT freely available for other researchers and collaborators through GitHub