Spring 2024

Solar Energy Research Group members Jonathan Turnley and Prof. Rakesh Agrawal’s Feature Article “Solution processed metal chalcogenide semiconductors for inorganic thin film photovoltaics” was published in RSC Chemical Communications.

Solar Energy Research Group member Shriya Khandelwal was awarded the Undergraduate Research Award. Congratulations, Shriya.

Solar Energy Research Group member Jonathan Turnley was awarded College of Engineering Outstanding Research Award. Congratulations Jonathan!

In collaboration with Prof. Edgardo Saucedo’s group at UPC Spain, Solar Energy Research Group members Jonathan W. Turnley, and Prof. Rakesh Agrawal’s manuscript “Novel synthesis of semiconductor chalcohalide anti-perovskites by low-temperature molecular precursor ink deposition methodologies” was published in Journal of Materials Chemistry C.

Solar Energy Research Group members Daniel C. Hayes, Samantha A. Langdon, Robert M. Spilker, and Prof. Rakesh Agrawal’s manuscript “Carbon Impurity Minimization of Solution-Processed, Thin-Film Photovoltaics via Ligand Engineering of CuInS2 Nanoparticles” was published in ACS Applied Energy Materials.

Fall 2023

In collaboration with Prof. Lydia Wong’s group at NTU Singapore, Solar Energy Research Group members Ryan Swope, and Prof. Rakesh Agrawal’s manuscript “Efficiency enhancement and doping type inversion in Cu2CdSnS4 solar cells by Ag substitution” was published in Journal of Materials Chemistry A.

Solar Energy Research Group members Shubhanshu Agarwal, Kyle Weideman, David Rokke, Kiruba Catherine Vincent, and Prof. Rakesh Agrawal’s manuscript “Enhancing the optoelectronic properties of solution-processed AgInSe2 thin films for application in photovoltaics” was published in Journal of Materials Chemistry C.

Solar Energy Research Group members Jonathan Turnley, Swapnil Deshmukh, Ryan Ellis, and Prof. Rakesh Agrawal’s manuscript “Molecular Precursor Approach to Sulfur-Free CuInSe2: Replacing Thiol Coordination in Soluble Metal Complexes” was published in ACS Omega.

Solar Energy Research Group member Jonathan Turnley was awarded 2nd place for his presentation at the AICHE Electronic and Photonic Materials: Graduate Student Awards session. Congratulations Jonathan!

Solar Energy Research Group members Apurva Pradhan, Scott McClary, Kyle Weideman, Shriya Khandelwal, Joseph Andler, David Rokke, and Prof. Rakesh Agrawal’s manuscript “Tuning the optoelectronic properties of enargite (Cu3AsS4) solar cells by Ag alloying: A DFT-informed synthesis” was published in Applied Physics Letters.

Solar Energy Research Group members Jonathan Turnley, Swapnil Deshmukh, Robert Spilker, and Prof. Rakesh Agrawal’s manuscript “A selenium-based “alkahest”: reactive dissolutions of metals and metal compounds with n-alkylammonium polyselenide solutions” was published in Inorganic Chemistry Frontiers.

Solar Energy Research Group members Shubhanshu Agarwal, Jonathan Turnley, Apurva Pradhan, and Prof. Rakesh Agrawal’s manuscript “Moderate Temperature Sulfurization and Selenization of Highly Stable Metal Oxides: An Opportunity for Chalcogenide Perovskite” was published in Journal of Materials Chemistry C.

Spring 2023

Separations Research Group Members Tony Mathew, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Relaxing the constant molar overflow assumption in distillation optimization” was published in AIChE Journal.

Solar Energy Research Group member Isabel Panicker was awarded 1st place in the Purdue AICHE undergraduate poster competition. Congratulations, Isabel!

After graduation, Solar Energy Research Group undergraduate Isabel Panicker will be going to Georgia Tech to get a PhD in chemical engineering. Congrats, Isabel!

After graduation, Solar Energy Research Group undergraduate Kevin Ng will be joining Parker Hannifin in their Engineering Leadership Development Program. Congrats, Kevin!

Solar Energy Research Group undergraduate Lily Whitmoyer has accepted a summer internship position with Washington River Protection Solutions. Congrats, Lily!

Solar Energy Research Group members Apurva Pradhan and Kiruba Catherine Vincent presented at the 2023 MRS Spring Meeting and Exhibit in San Francisco, California.

Solar Energy Research Group member Jonathan Turnley presented at the ACS Spring 2023 meeting in Indianapolis, Indiana.

Solar Energy Research Group member Jonathan Turnley presented at the 2023 Gordon Research Conference on Nanomaterials for Applications in Energy Technology in Ventura, California.

The Purdue OTC announced in their March update that Prof. Rakesh Agrawal, Zewei Chen, and Peter Oladipupo received a patent titled “Electrically Heated Dehydrogenation Process“.

Solar Energy Research Group members Apurva Pradhan, Shubhanshu Agarwal, Jonathan Turnley, Shriya Khandelwal, Ryan Swope, and Prof. Rakesh Agrawal’s manuscript “Synthesis of BaZrS3 and BaHfS3 Chalcogenide Perovskite Films Using Single-Phase Molecular Precursors at Moderate Temperatures” was published in Angewandte Chemie International Edition.

Solar Energy Research Group members Kiruba Catherine Vincent, Shubhanshu Agarwal, Jonathan Turnley, and Prof. Rakesh Agrawal’s manuscript “Liquid Flux-Assisted Mechanism for Modest Temperature Synthesis of Large-Grain BaZrS3 and BaHfS3 Chalcogenide Perovskites” was published in Advanced Energy & Sustainability Research.

Fall 2022

In collaboration with ExxonMobil’s Research Group, Separations Research Group Members Tony Mathew, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Advances in distillation: Significant reductions in energy consumption and carbon dioxide emissions for crude oil separation” was published in Joule.

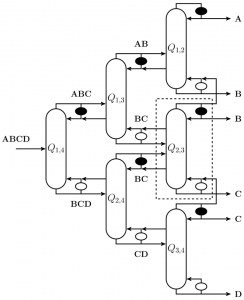

Separations Research Group Members Zheyu Jiang, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Minimum reflux calculation for multicomponent distillation in multi-feed, multi-product columns: Mathematical model” was published in AIChE Journal.

Solar Energy Research Group member Jonathan Turnley presented at the 2022 MRS Fall Meeting and Exhibit in Boston, Massachusetts.

Solar Energy Research Group members Jonathan Turnley, Apurva Pradhan, Daniel Hayes, and Shubhanshu Agarwal presented at the 2022 AIChE Annual Meeting in Phoenix, Arizona.

Solar Energy Research Group members Jonathan Turnley, Kiruba Catherine Vincent, Apurva Pradhan, Isabel Panicker, Ryan Swope, and Prof. Rakesh Agrawal’s manuscript “Solution Deposition for Chalcogenide Perovskites: A Low-Temperature Route to BaMS3 Materials (M = Ti, Zr, Hf)” was published in Journal of the American Chemical Society.

Separations Research Group Members Akash Sanjay Nogaja, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Identifying Heat-Integrated Energy-Efficient Multicomponent Distillation Configurations” was published in I&EC Research Journal.

Separations Research Group Members Radhakrishna Tumbalam Gooty, Prof. Rakesh Agrawal, and Prof. Mohit Tawarmalani’s manuscript “Advances in MINLP to Identify Energy-Efficient Distillation Configurations” was published in Operations Research Journal.

Summer 2022

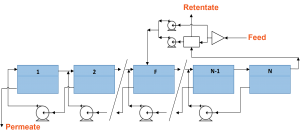

Separations Research Group Members Jose Adrian Chavez Velasco, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Which separation scenarios are advantageous for membranes or distillations?” was published in AIChE Journal.

Solar Energy Research Group member Kevin Ng was awarded the Best Presentation Award at the Purdue Summer Undergraduate Research Symposium. Congratulations Kevin!

Separations Research Group member Tony Mathew won the 2022 Graduate Student Research Award of the Distillation and Absorption Area of AIChE Separations Division. Congratulations Tony!

Spring 2022

Solar Energy Research Group member Apurva Pradhan was awarded the 2022 ChE Excellence in Safety award. Congratulations Apurva!

Solar Energy Research Group member Isabel Panicker’s poster received 2nd place in the College of Engineering at Purdue’s 2022 Spring Undergraduate Research Conference. Congratulations Isabel!

Solar Energy Research Group member David Rokke successfully defended his thesis and has accepted a position at Applied Materials. Congratulations David!

Solar Energy Research Group members David Rokke, Essam Alruqobah, and Prof. Rakesh Agrawal’s review article “Extrinsic Doping of Ink-Based Cu(In,Ga)(S,Se)2-Absorbers for Photovoltaic Applications” was published in Advanced Energy Materials.

Solar Energy Research Group members Swapnil Deshmukh, Caleb Miskin, Apurva Pradhan, and Prof. Rakesh Agrawal’s manuscript “Solution Processed Fabrication of Se-Te Alloy Thin Films for Application in PV Devices” was published in ACS Applied Energy Materials.

Solar Energy Research Group members Swapnil Deshmukh, Kyle Weideman, Ryan Ellis, and Prof. Rakesh Agrawal’s manuscript “Enabling fine-grain free 2-micron thick CISe/CIGSe film fabrication via a non-hydrazine based solution processing route” was published in Materials Advances.

Solar Energy Research Group members Joseph Andler, Xianyi Hu, Scott McClary, and Prof. Rakesh Agrawal’s manuscript “Analysis of enargite thin films synthesized from carbon-containing and novel carbon-free processing methods” was published in Materials Science in Semiconductor Processing.

Fall 2021

Solar Energy Research Group members Ryan Ellis, Swapnil Deshmukh, Jonathan Turnley, Dwi Sutandar, Jacob Fields, and Prof. Rakesh Agrawal’s manuscript “Direct Synthesis of Sulfide-Capped Nanoparticles for Carbon-Free Solution-Processed Photovoltaics” was published in ACS Applied Nano Materials.

Energy System Group Members Zewei Chen, Yiru Li, Wasiu Peter Oladipupo, Edwin Rodriguez, Gary Sawyer, and Prof. Rakesh Agrawal’s manuscript “Alternative ordering of process hierarchy for more efficient and cost-effective valorization of shale resources” was published in Cell Reports Physical Science.

Energy System Group Undergraduate Researcher Arsh Bhatia received OUR scholarship for 2021-2022 academic year. Congratulations Arsh!

Summer 2021

Separations Research Group Members Jose Adrian Chavez Velasco, Zewei Chen, Radhakrishna Tumbalam Gooty, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Energy-efficient membrane cascades for industrial separations” was published in Computer Aided Chemical Engineering.

Separations Research Group Members Tony Joseph Mathew, Radhakrishna Tumbalam Gooty, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “A Simple Criterion for Feasibility of Heat Integration between Distillation Streams Based on Relative Volatilities” was published in Industrial & Engineering Chemistry Research.

Separations Research Group Members Jose Adrian Chavez Velasco, Radhakrishna Tumbalam Gooty, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Optimal design of membrane cascades for gaseous and liquid mixtures via MINLP” was published in Journal of Membrane Science.

Separations Research Group member Tony Joseph Mathew successfully defended his thesis. Congratulations Tony!

Separations Research Group Members Radhakrishna Tumbalam Gooty, Jose Adrian Chavez Velasco, and Prof. Rakesh Agrawal’s manuscript “Methods to Assess Numerous Distillation Schemes for Binary Mixtures” was published in Chemical Engineering Research and Design.

Spring 2021

Tony Joseph Mathew and Zewei Chen both gave oral presentations at the 2021 AIChE Spring Meeting

Solar Energy Research Group member Swapnil Dattatray Deshmukh received the Outstanding Research Award 2021 from the College of Engineering. Congratulations, Swapnil!

Separations Research Group Member Jose Adrian Chavez Velasco, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Systematic Analysis Reveals Thermal Separations Are Not Necessarily Most Energy Intensive” was published in Joule.

Fall 2020

Energy Systems Research Group member Zewei Chen received the Bill Murray Fellowship for 2020-21 academic year. Congratulations Zewei!

Separations Research Group members Tony Joseph Mathew, Radhakrishna Tumbalam Gooty, Prof. Mohit Tawarmalani, and Prof. Rakesh Agrawal’s manuscript “Quickly Assess Distillation Columns” was published in Chemical Engineering Progress.

Solar Energy Research Group member Swapnil Deshmukh won the Second Place Award in the 2020 AIChE Graduate Student Award Competition in the Inorganic Chemistry Area. Congratulations Swapnil!

Separations Research Group member Radhakrishna Tumbalam Gooty successfully defended his thesis. Congratulations Radhakrishna!

Summer 2020

Tony Joseph Mathew received first place for his Oral Presentation in the Energy and Process Intensification & Biotechnology category, and won the Best Overall award, at the 29th Annual Symposium organized by Chemical Engineering Graduate Student Organization. Congratulations, Tony!

David Rokke received first place for his Oral Presentation in the Material Science category at the 29th Annual Symposium organized by Chemical Engineering Graduate Student Organization. Congratulations, David!

Solar Energy Research Group members David Rokke and Swapnil Deshmukh’s submissions to the 2020 Annual AIChE conference are accepted for an oral presentation and two Graduate Student Award Oral Presentations respectively.