'More eager, more agile, more visible'

Over the past year, we have set new records in research excellence, with three new national centers and the highest level of research funding ever. We have grown our undergraduate enrollment and become the largest engineering college among the nation’s top 10. We have also received $176 million in philanthropic support, the highest in our history. Thank you all.

As a public land-grant university, we are proud of our scale. We also aspire to attain the “Pinnacle of Excellence at Scale.”

We will provide diverse, innovative choices and support the highest academic standards for each student, even at scale. We will make online learning not only scalable but also effective.

We will become the best engineering college in the world at the interface of virtual-physical engineering, by leveraging long-standing strength in “what-we-touch” engineering and growing “what-we-code” engineering.

We will be the best engineering college in the country in engaging industry in all areas, including curriculum innovation, workforce development, research impact and entrepreneurship.

These efforts are gaining momentum. Enthusiastic support from our 93,000+ alumni and many partners is essential. On the 2018 Purdue Day of Giving, your generosity broke the record of single-day gifts to one college: 2,406 gifts were provided to enable the future of Purdue Engineering.

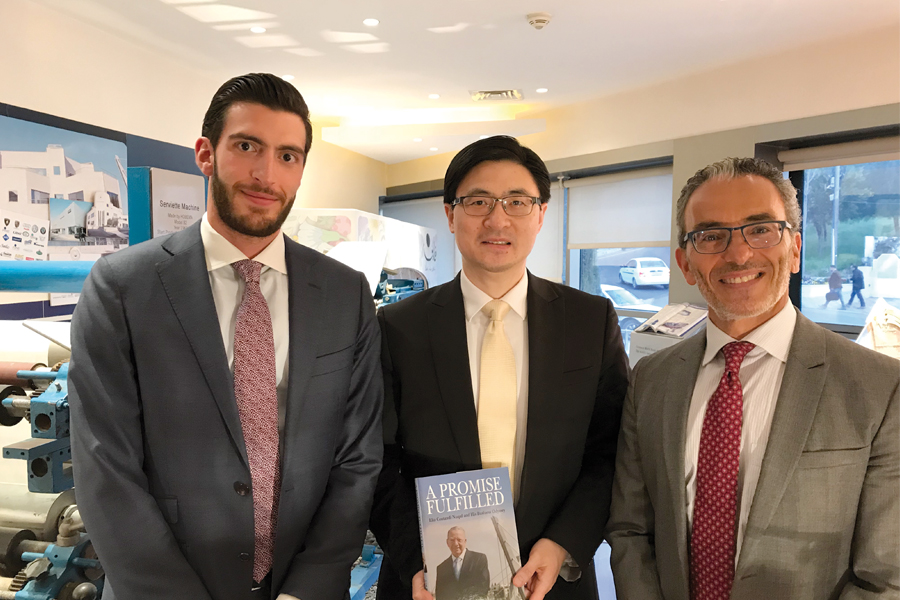

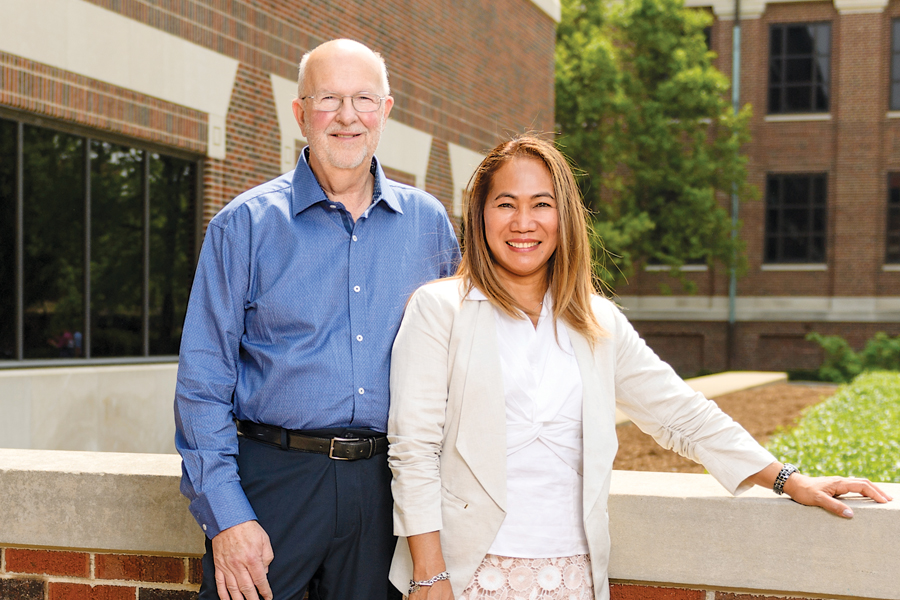

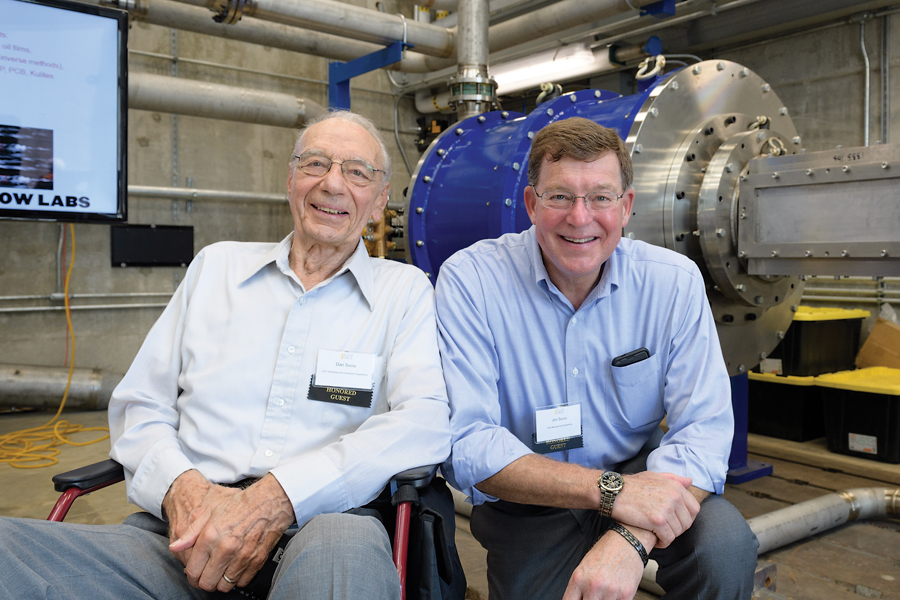

For fiscal-year contributions to the college’s programs, schools and research centers.

For fiscal-year contributions to the college’s programs, schools and research centers.