Resources

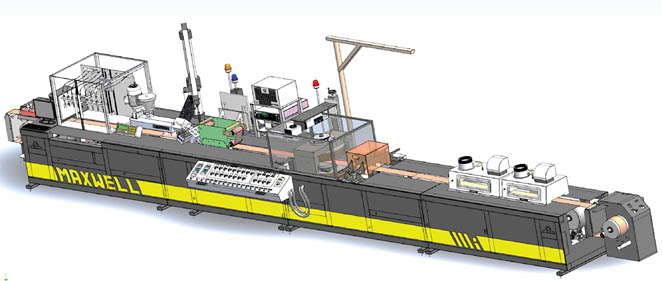

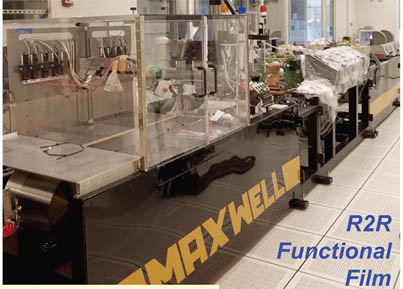

Birck Nanotechnology Center has an exceptional inventory of scalable manufacturing tools. One unparalleled resource is the center’s 45-ft-long manufacturing line, located in Birck’s clean room, to produce functional film with enhanced through thickness electrical, magnetic, thermal and dielectric properties.

The Birck Nanotechnology Center in Discovery Park is a $90 million, state-of-the-art nanofabrication and characterization facility that has already engaged leading research groups in nanoelectronics, nanophotonics, MEMS, RF IC design, nanobiotechnology sensors, composite manufacturing, polymer processing, and analytic chemistry. Since 2014, Purdue has invested $3 million in new smart film tools and is leading the Indiana node for the U.S. Department of Defense’s five-year, $171 million effort to launch the Flexible Hybrid Electronics Manufacturing Innovation Institute (NextFlex). Through Birck, the institute focuses on the design, manufacturing and integration of electronics and sensors as well as disposable devices. A pilot IoT/sensor manufacturing plant is being setup which provides an anchor investment to entirely new opportunities for the region. The pilot facility is anticipated to become a magnet attracting high-tech companies to work closely with traditional industries in the Midwest. Current industry partners include United Technologies, Applied Materials, Landauer, Bayer and Sartorius.

Roll-to-Roll manufacturing consists of a set of processes and related equipment that constitute a means to automate, increase throughput, and improve reliability of manual or batch processes.

Typically, roll-to-roll processes are sought when promising technologies are scaled-up, because roll-to-roll processes offer the throughput and competitive economics that provide enough low-cost samples for statistical evaluation of a technology in controlled settings and, eventually, in the marketplace.

- Manufacturing Capabilities

- Printing Flexible Electronics

- Off-line Metrology

- In-line Non-contact Metrology

- Roll-to-roll Film Casting

- Manufacturing of Z-Oriented Films

On-Site Research

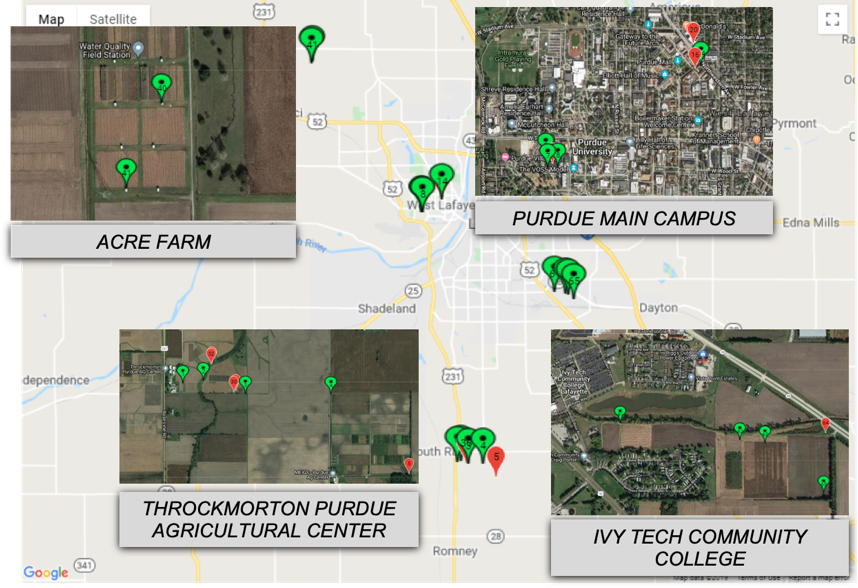

SMART Films Consortium collaborates closely with researchers engaged on the $40 million Purdue-WHIN grant project, which is focused on testbeds throughout the 10-county region. As a result, SMART Films has research sites throughout campus and the community – allowing researchers to conduct work on-location, from campus-operated farms to manufacturing plants throughout the community. This provides real-world insights that improve insights and overall outcomes.