Research

Nanomanufacturing preeminent team involves two dozen faculty across ten Schools and four Colleges to combine advances in roll-to-roll systems, functional printing and scalable nanomanufacturing to enable wide spread use of IoT and digital technology.

Summer 2021 Report

The Purdue SMART Films Consortium has prepared a Summer 2021 Report of several of our faculty members' research highlights. We are grateful for the Consortium members and many others who helped make this work possible.

Research Focus Areas

Novel Functional Materials and Manufacturing

Research to develop novel functional materials and polymer composites as well as scalable manufacturing techniques to make low-cost internet of things (IoT) devices. Activities range from first principle material design to extensive in-line characterization for process optimization. Capabilities include various printing, coating, and laser processing techniques as well as a custom-built roll-to-roll multi-functional film manufacturing line.

Data Analytics and Device Modeling

Low-cost devices and electronics produced by roll-to-roll manufacturing are different compared the existing solutions using integrated circuit fabrication techniques. There is more variability, but we have pioneered a novel design paradigm where sensor diversity and physics-guided machine learning and statistical techniques are used to make accurate measurements in noisy and harsh outside environment.

IoT Devices and Sensors

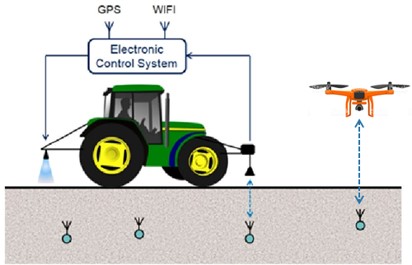

Low-cost IoT devices enable new applications in digital agriculture, water quality monitoring, smart food packaging, digital health, point of care diagnostics, wearables, human performance monitoring, soft robotics, next generation manufacturing, and smart infrastructure.

IoT Systems (Electronics, Applications, Testbeds)

Research on hybrid integrated circuit integration, communication, and networking to get data from low-cost sensors to the cloud. Testbeds at Purdue agricultural farms and the Indiana Manufacturing Institute, as well as with collaborators in veterinary medicine, pharmacy, and health and human sciences enable us to test the latest IoT systems in diverse real-world applications. Through the $19.8M Wabash Heartland Innovation Network (WHIN) project, we have a developed a living laboratory for digital ag and smart manufacturing in the ten counties surrounding Purdue.

Education and Workforce Development

IoT sensors and smart devices provide a large amount of data in the digital factory environment. We have researchers focused on artificial intelligence/ human interface and how to train the next generation of smart factory workers. They also study ethical and societal impacts of IoT and AI technologies.

Quick Glimpse: Faculty Research Projects

Data Analytics and Device Modeling

High precision sensing with low-cost sensors in out-of-laboratory conditions

Prof. Muhammad Ashraful Alam

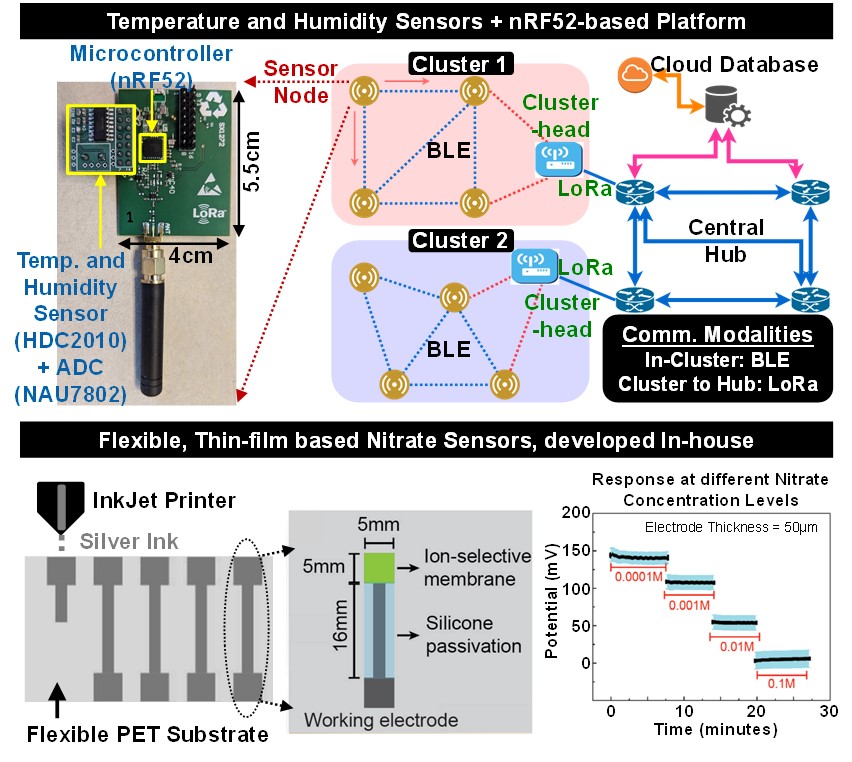

- Continuous Nitrate monitoring of agricultural fields

- Design principles and sensitivity limits of ion-selective sensors

- Zero-energy thermometer using ISEs

- Temperature variation compensation in self-calibration method

- Statistical sensing or crowd sensing: In praise of averages

Physics Models for Bio and Electro-chemical Sensors

Prof. Ashraf Alam

-

Design principles and sensitivity limits of ion-selective sensors

- Continuous measurement using large number of nominally identical components

- Statistical sensing or crowd sensing: In praise of averages

- Reliable-sensing with unreliable sensors

-

Physics-guided machine learning

- Physics-based generalization of ML for out-of-domain prediction

- Characterize-as-you-build to obviate component testing

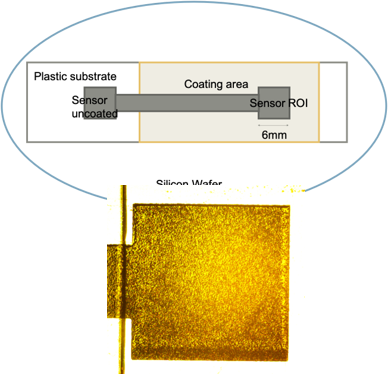

Image-Based Artificial Intelligence for Nitrate Sensor Performance Prediction

Prof. Jan Allebach

Developing the capability to manufacture at high-volume and low cost thin-film nitrate sensors and other active devices using R2R printing technologies

- Capture in-line images of manufactured sensors in real-time directly from the web in R2R system.

- Use AI-based methods to predict sensor performance from image data fused with manufacturing parameters and field data.

- Develop AI methods for on-line learning to update parameters of predictor in real-time as new data is acquired

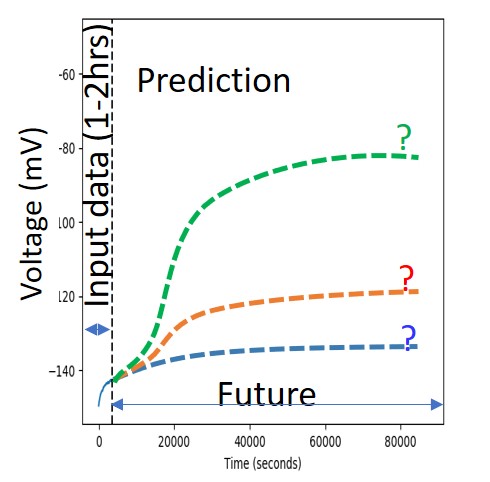

Machine Learning for Fast Chemical Sensing

Prof. Bruno Ribeiro, S. Chandra Mouli

- Goal: Design robust machine learning methods for faster prediction of chemical concentrations

- Approach: Hybrid Physics & Deep learning method that combines robustness of physics modeling with adaptability of machine learning

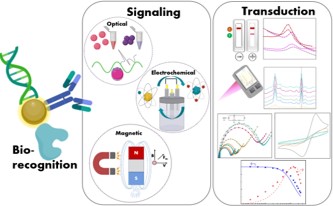

IoT Devices and Sensors

Colorimetric Point-of-Care Biosensors for COVID-19 And Bovine Respiratory Disease

Prof. Mohit Verma

- Biosensors can be used in the field to detect COVID-19 respiratory disease in humans and bovine respiratory disease in cattle

- Saliva samples to detect the RNA from SARS-CoV-2 within 60 minutes and provide a color change on a paper strip that is visible to the naked eye

- Cattle nasal swab with a sous vide water bath demonstrate field results were comparable to in-lab results at 60-100% concordance

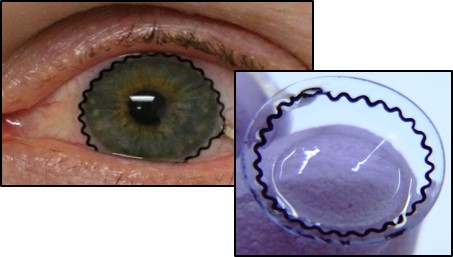

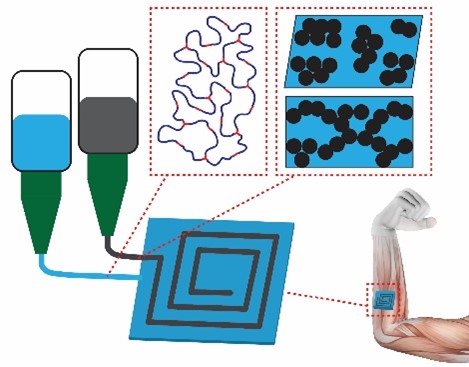

Designing Next-Generation Polymers to Enable Wearable Bioelectronic Devices

Prof. Bryan W. Boudouris, Chi Hwan Lee and Georgia Malandraki

-

High-performance ERG Sensors Printed on Contact Lenses Perform Better than Commercial Sensors

- Radical Polymers Significantly Enhance the Performance of OECT Sensor Devices

Smart Textile for Human - Machine Interaction

Prof. Tian Li

- Redesign traditional textile fibers through structural engineering and chemical modification

- Transform fabric into a Human-Machine Interactive Platform

- Ion & Electron Regulation

- Comfortable, Biocompatible and Breathable Devices with Naturally Nanostructured Fibers.

Passive Sensors: Soil and Agriculture Health

Prof. Rahim Rahimi

Wireless passive sensors

- Battery free and wireless sensors for subsoil health monitoring

- Printed radiation dosimeter for monitoring sterilization

Agriculture sensors and packaging

- Highly stable all-printed ion selective nitrate and reference electrode

- Microbial activity sensor

- Printed sensor packaging for field deployment

Aptasensors for Food and Agriculture

Prof. Lia Stanciu

Growing market: food safety & agriculture; Market segment projected to reach USD$ 14.6 billion by 2025 for biosensors only;- Printing DNA aptamer layers in a R2R Fashion

- Demonstrate repeatable detection over >50 sensors.

- Demonstrate on-site testing in real samples

- Continuous sensing and Aptamer-Electrode Bond Stability

- Reproducibility analysis and improving process control

- Enhance sensitivity, determine the effect of pH, selectivity, coating optimization

Miniaturization & integration of pH sensors

Prof. Alexander Wei

Thin-film sensors that can be incorporated into the lining of sterilized bags and other disposable plasticware- Thin-film pH electrode that survives 50-kGy γ-irradiation

- Stable pH readings after 28-day immersion (in PBS)

- Low sensitivity to variations in salt concentration

IoT Systems (Electronics, Applications, Testbeds)

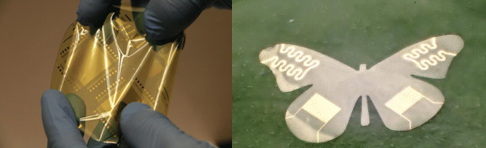

Futuristic electronics involving CMOS technology

Prof. Muhammad Mustafa Hussain

- Innovative widgets both physically rigid and fully flexible and stretchable

- Focused on healthcare technology, environmental monitoring, agricultural and industrial productivity, mobility, defense and renewable energy applications

Detection of Volatile organic compounds for agriculture

Profs. Saeed Mohamadi, Lia Stanciu, Yen Yu Chen & Nojan Aliahmad

- Tunable VOC response

- Good stability

- Ultrafast response/recovery

-

Hybrid-enhanced response

- Selective detection towards oxygen-containing VOCs

- Significantly higher VOC-sensitivity

Printable thin film transistors and ICs on flexible substrate

Prof. Saeed Mohammadi, Yuhang Zhu, Nojan Aliahmad

- IGZO/IZTO TFTs are flexible, reliable, transparent and can achieve high performance

- They can be used for analog interface ICs with standard R2R printing technology

- They can be used for wireless communication / energy harvesting with standard R2R printing / shrinkable polymer technology

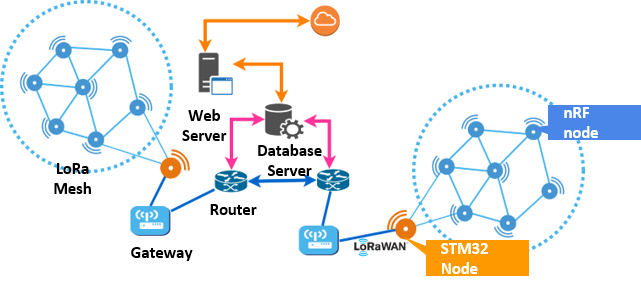

WHIN/SMART IoT Sensor Deployment and Edge Analytics

Prof. Saurabh Bagchi, Charilaos Mousoulis, Nithin Raghunathan, Xiaofan Jiang, Pengcheng Wang, Heng Zhang, Shikhar Suryavansh, Profs. Shreyas Sen, Dimitrios Peroulis, Ali Shakouri

YouTube Link: https://youtu.be/fzea3KeO3bQ

Reliable IoT Networks & Deployment

- Sensor nodes and receiver can be separated by miles

- The use of mesh network allows for transparent failover

- Transmission power control to adapt to varying distances to next hop

In-sensor Analytics & Visualization

- Run lightweight analytics close to the source of data

- Reduce communication back to the server

- Ensure prompt anomaly detection

Self-powered Sensors with Energy-harvested Ultra-Low Power Time-domain Sensing

Prof. Shreyas Sen

Applicable for: Temperature, Humidity, Nitrate concentration

- Distributed Connected Sensor Nodes

- Communication Energy >> Compute Energy

- In-Sensor Analytics >> Improve bits/information

- Context-Aware Dynamic Adaptation of Comp and Comm >> Efficient Connected SMART Sensors

Novel Functional Materials and Manufacturing

Materials Processing for Printing of Structural and Electronic Devices

Prof. Alex Chortos

- Elastomers and polymers with custom mechanical properties

- Ink rheology for improved print fidelity

- Composite materials with tailored deformation-dependent properties

- Electromechanical devices for medical and monitoring applications

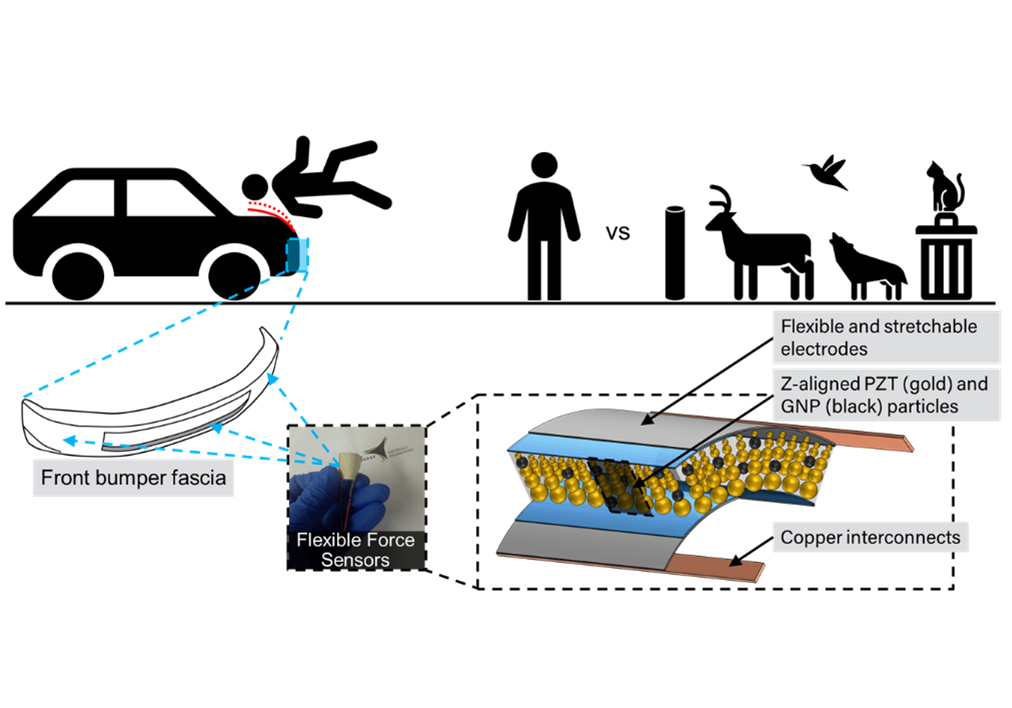

Piezoelectric Films with Z oriented nanocolumns as Low-cost Impact Sensors: Vehicle E-Skin Application

Prof. Miko Cakmak

- A bio-inspired electronic skin (E-skin) with a dense array of mechanically flexible and multifunctional sensors

- Nanocolumns of piezoelectric structures oriented in thickness direction greatly enhances thickness-mode impact performance

- Rapid, repeatable, and robust voltage response

- 10 ms detection time

- Mechanically flexible sensors can intimately interface with a curvilinear geometry

- Ideal for contact-based measurements

- Roll to Roll Continuous Manufacturing for scale up

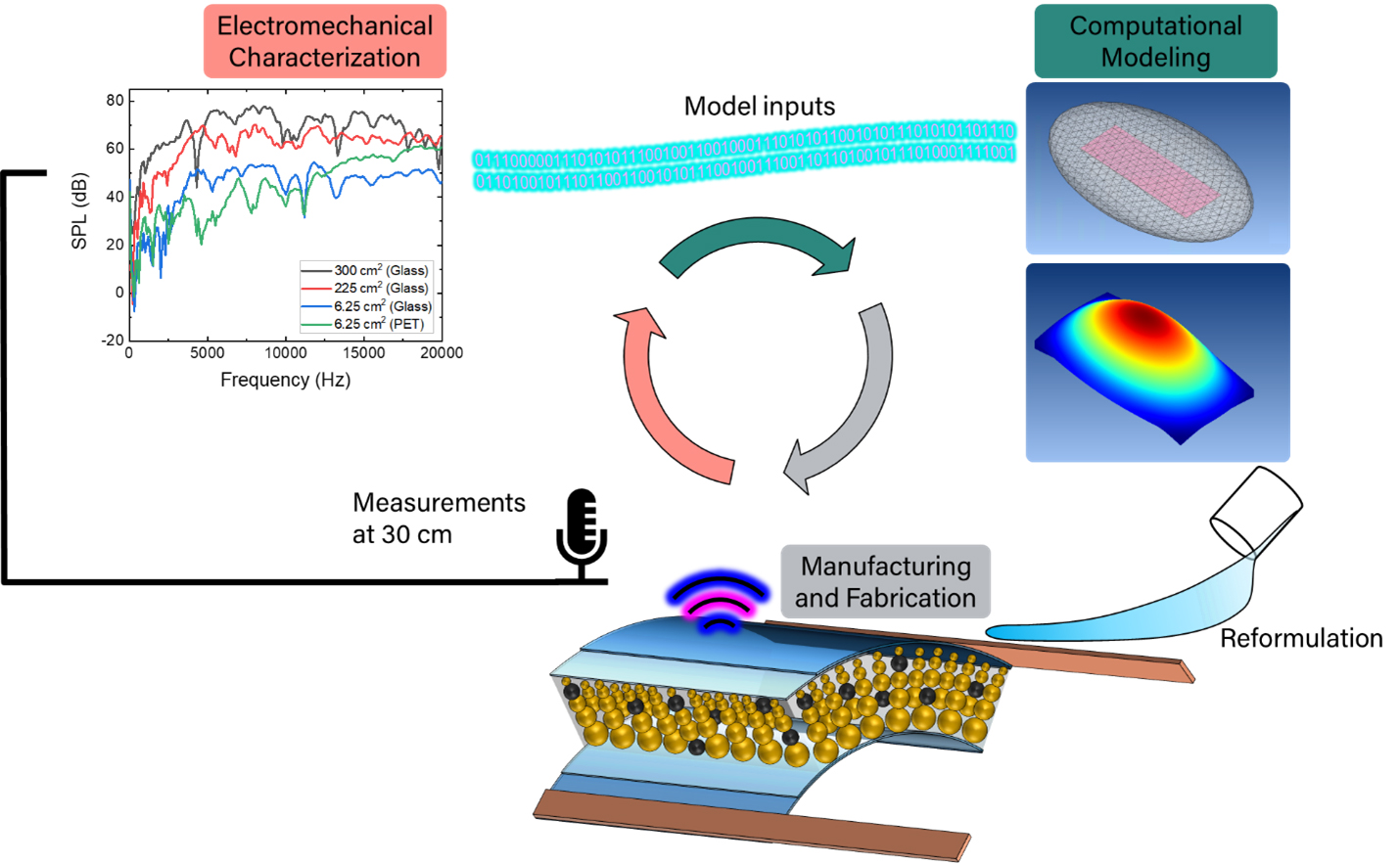

Flat-panel Transparent Piezoelectric Loudspeakers

Prof. Miko Cakmak

- Advancing the fields of wearable devices and flexible electronics with flat-panel and conformable loudspeakers

- Sound pressure levels up to 80 dB at 30 cm

- Piezoelectric composites anisotropically combine the advantageous properties of piezoceramics and polymers

- Roll to Roll Continuous Manufacturing for scale up

- Thin, flexible, lightweight, and optically transparent

- Flexible design allows for iterative improvement, with feedback from electromechanical characterization and computational modeling

- Ideal for immersive soundscapes and acoustic environments

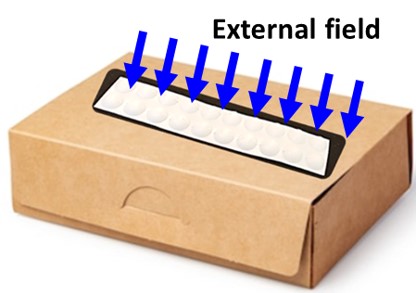

Programmable Mechanical Sensors with Time History: from Food to Agriculture Applications

Prof. Andres F. Arrieta

-

Develop flexible sensors recording time-variations with zero power requirements

- Environment responsiveness

- Memory writing threshold design

- Proof-of-concept of spatiotemporal sensing

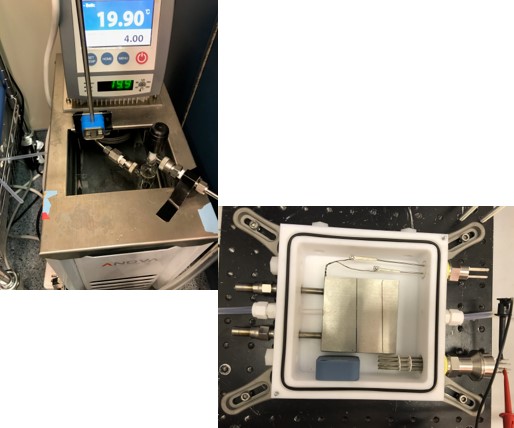

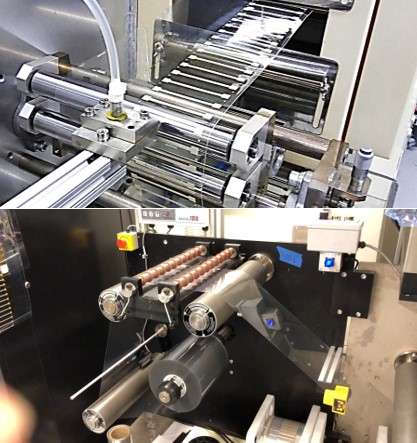

Roll-to-Roll Fabrication and Characterization of Piezoelectric and Agricultural Sensors

Prof. M. Cakmak, N. Glassmaker, Y. Mi, S. Shams Es-Haghi, G. Telesnicki, Prof. A. Shakouri

R2R Manufacturing YouTube Link: https://youtu.be/uSjJpJX3Hs8

Flexible piezoelectric devices YouTube Link: https://youtu.be/Q8BiXaTiZKg

-

Roll-to-Roll Manufacturing Progress

- Expansion of slot-die coating process window for fabricating ion selective membranes on Mirwec.

- Demonstration of fully automated and in-line thickness measurements and imaging during slot die coating.

- New insights and next steps

-

Piezoelectric Sensor

- --Roll-to-roll processing for low cost sensors and loudspeakers

NSF Future Manufacturing Grant (2021-2025, $3M)

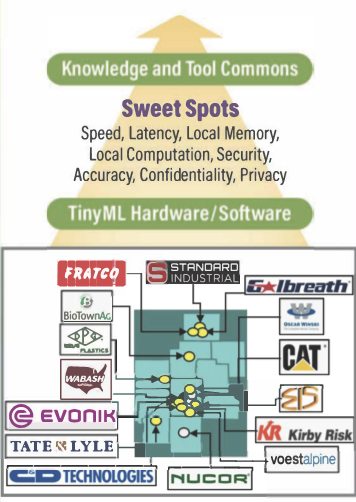

FMRG: Manufacturing USA: Cyber: Privacy-Preserving Tiny Machine Learning Edge Analytics to Enable AI-Commons for Secure Manufacturing

Purdue: Shakouri (PI), Alam, Allebach, Bertino, Magana, Mansson

Harvard: Sweeney, Janapa Reddi, Narayanamurti + Ivy Tech Community College & Tuskegee

Current manufacturing systems based on a global supply chain work well, producing high-volume products at low cost. However, they are fragile to perturbations (e.g., COVID-19) and even processes that are essential to success, such as new product development and manufacturing ramp-up and optimization, can be prohibitively lengthy and expensive. Artificial Intelligence (AI) has revolutionized many industries and can be an important tool to improve the productivity and agility of manufacturing, but progress has been slow in manufacturing. This project proposes a fundamental reimagination of distributed AI/ML techniques to transform the future of manufacturing by establishing an AI-Commons that bridges multiple sites and companies using secure, distributed machine learning (ML), incentivized information sharing, and continuous quality improvement and training. This addresses a critical shortcoming of the current approach to AI in manufacturing; the limitation of training data to in-company data. Since AI algorithms increase in power with more data, secure data sharing and aggregation has the potential to provide vastly better AI solutions to all manufacturers. The project will also research the edge computation hardware needed to execute the resulting algorithms on the factory floor. The team will work closely with Ivy Tech Community College and the Vertically Integrated Projects program, which helps students from Purdue, Harvard, and Tuskegee University work on industry-defined manufacturing AI projects.

This project’s goal will be achieved by fulfilling the following four objectives: (1) Co-optimization of Tiny Machine Learning (TinyML) hardware and software for manufacturing; (2) Design of privacy and confidentiality policies for an AI-Commons that encourages and incentivizes knowledge sharing; (3) Demonstration of data aggregation and predictive technical cost modeling for some foundational manufacturing processes; and (4) Introduction of AI in manufacturing curricula and integration with workforce development. A key focus is on AI system deployment to obtain necessary data for optimization of ML algorithms for common manufacturing processes in pharmaceutical, food processing, job shop machining, and hybrid composite materials. The project team has developed a strong partnership with small and large manufacturers in the Wabash Heartland Innovation Network (WHIN) region in Indiana. TinyML devices will be deployed throughout this region, where the sharing of data and AI could improve operations significantly.

For more details, please inquire about accessing the SMART Consortium's Member's Only section by contacting Sangeeta Abrol, abrols@purdue.edu.