The next generation of propulsion is closer than ever. A revolutionary design, called a rotating detonation engine (RDE) has been the elusive the “holy grail” for decades. The supersonic dance happening inside an RDE promises to generate the same or more thrust as traditional rocket engine, but in a much smaller package.

After years of slow but steady progress, RDE development is now blazing — and Purdue’s early start, unique capabilities, and top-level expertise put Boilermakers at the forefront of this field. Purdue researchers even contributed to NASA’s first full-scale test of a rotating detonation rocket engine in 2022.

Stephen Heister, the Raisbeck Engineering Distinguished Professor of Aeronautics and Astronautics, draws a comparison between a rotating detonation rocket engine (RDRE) and NASA’s time-honored RL-10. Originally designed in the 1950s and used on countless satellite and deep space exploration launches, versions of that rocket engine are still part of satellite launch systems today.

An RDRE that produces similar thrust to the RL-10 could be as much as 40 percent shorter in length. That factor alone could be transformational for spacecraft design.

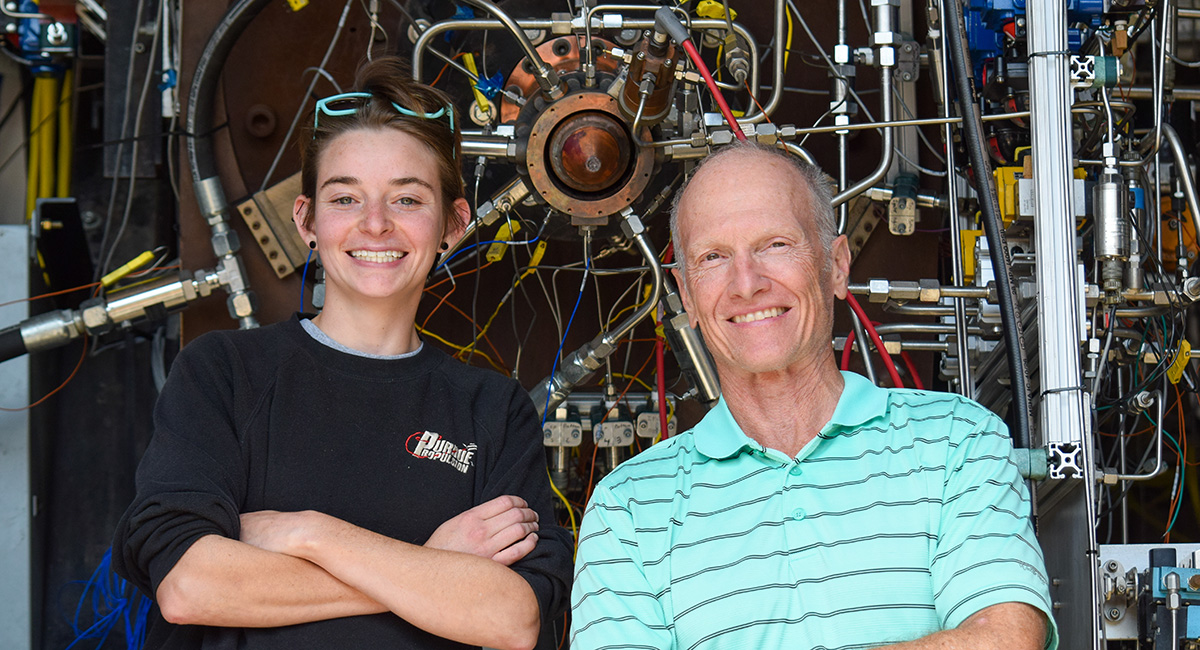

AAE doctoral student Ariana Martinez with Stephen Heister, the Raisbeck Engineering Distinguished Professor of Aeronautics and Astronautics. (Purdue University photo/Alan Cesar).

“If we want to do a Neil Armstrong and land on the Moon, one factor in the design of the lunar lander is the length of the rocket underneath it. With a shorter engine, you could have shorter landing gear, meaning the lander can fit in a smaller launch vehicle. If we do everything right, an RDRE with just a few percent more thrust could double the payload of the launch vehicle,” Heister says. "The power density—the amount of energy release we get within a certain volume—is an order of magnitude higher than today’s devices."

This game-changing engine design is also useful in Earth-bound applications. Carson Slabaugh, the Paula Feuer Associate Professor of Aeronautics and Astronautics, is looking at RDEs for high-speed vehicles traveling within the atmosphere.

“Aircraft weapons bays are not getting bigger, and yet we want longer range and higher flight speeds from those missiles,” Slabaugh says. “These engines give us a step change, a big jump in efficiency to make those things possible.”

Rotating detonation engines try to harness what’s called combustion instability — a phenomenon that engineers try to eliminate in traditional rockets. These are uncontrolled acoustic instabilities that can, under the right circumstances, grow in strength to supersonic detonation waves inside a combustion chamber. Many failures on traditional rockets have been attributed to this instability because the chamber was not designed to sustain them.

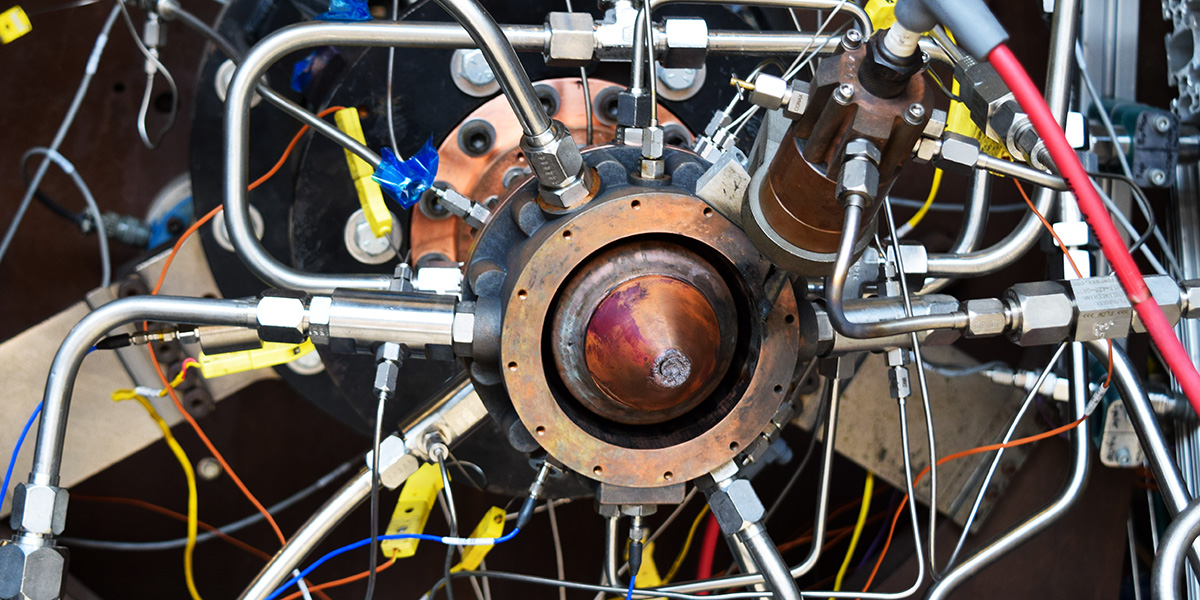

Researchers have been trying to exploit the waves by inducing them inside a ring-shaped channel. If they get the shape and injection conditions right, these shock waves don’t bounce back and forth: They whiz around the ring at supersonic speed, compressing and burning the air-fuel mixture as they go. That is, if you can keep them going.

In a rotating detonation engine, the combustion wave propagates continuously around the ring-shaped channel between the inner and outer sections. The liquid-cooled engine above, designed at Purdue and 3D-printed by NASA, still fires up even after enduring dozens of runs at Zucrow Labs. (Purdue University photo/Alan Cesar).

“In an RDE, the burning process is unsteady, making it really hard to sustain. These waves move at more than a mile per second, which means we’ve got about 100 microseconds between each wave passage to inject propellants and get them mixed,” Slabaugh says. “It’s a challenge to diagnose what’s happening and make design decisions.”

These challenges are what make Purdue the best place for RDE research. Heister has been working on these designs since 2007, and Slabaugh has developed diagnostic techniques for high-speed combustion. Zucrow Labs has the high-speed lasers, cameras, and other tools needed to make sense of the complex thermal fluxes happening inside the combustion ring — not to mention the fuel supply to fire one up.

“RDEs consume a tremendous amount of propellant, and if you try to make it too small, it just won’t work. You need flow systems that are only available at Zucrow to successfully test these,” Slabaugh says.

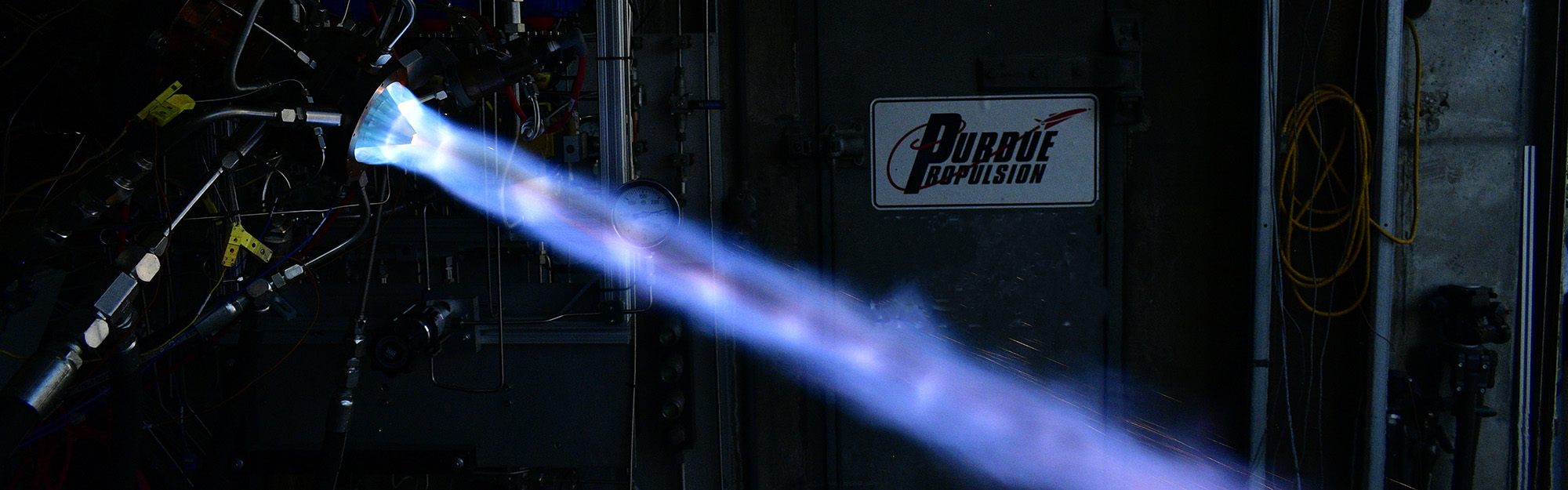

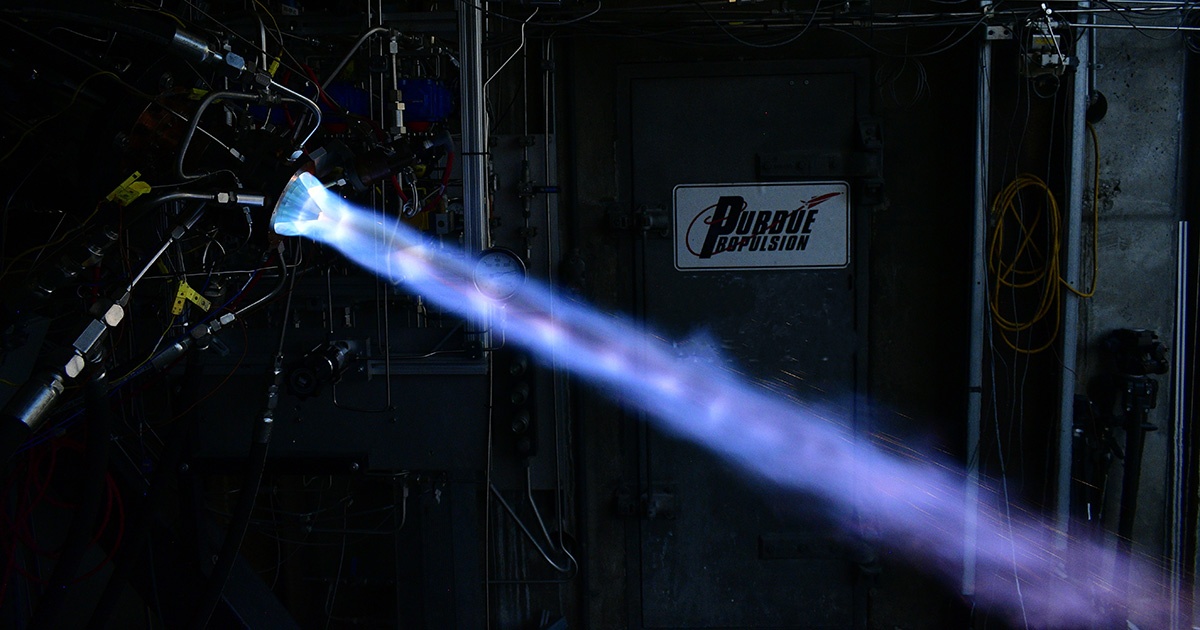

The result, once you have it going, is a high-temperature dance that produces a lot of heat, a lot of thrust, and a gorgeous blue-purple spiral of perfectly spent kerosene.

Hear Steve Heister talk about the development of RDRE technology on NASA's Houston, We Have a Podcast, episode 296. Visit the episode page for a full transcript.

The level of development and testing happening now at Zucrow Labs is unrivaled in academia, Heister says. Other universities running RDRE combustion experiments are burning gaseous fuel and oxygen, and with engines that use a solid metal center to absorb its copious heat energy. Those can only run for about a second before the metal reaches thermal capacity and begins melting away.

While useful for research, it’s far from the demands of a real-world engine that must run for minutes at a time. In 2022, while studying under Heister, then-student John Smallwood (PhD AAE ’23) built and tested Purdue’s first water-cooled RDRE. His design endured 120 hot-fires, some with 30-second runs, and still looked pristine when they cut it open afterward.

Encouraged by those results, AAE doctoral student Ariana Martinez had to push farther.

The ability to design and test liquid-cooled RDEs like this one, codenamed Panther, is unrivaled in academia, says distinguished professor Steve Heister. (Purdue University photo/Ariana Martinez).

“We wanted to bring an aggressive hardware design that takes us one step closer to a flight-like system. This combustor offers elevated chamber pressures, extended run durations, a contoured nozzle, and advanced 3D printing techniques.” she says.

In her approach, Martinez threw away the limitations of traditional metalworking techniques like computer numerical control (CNC) machining. She looked to NASA’s success with 3D-printing an exotic copper alloy, called GRCop-42, and began the engine she called Panther. Face nearly pressed to her computer screen, Martinez spent countless hours in CAD software to work out the complex geometries needed to make Panther run.

“Another issue for RDE research is that we’re using a liquid fuel. It’s much tricker to get a liquid and a gas to mix together properly. Ariana has come up with some clever injector concepts to address that,” Heister says.

Martinez collaborated with NASA Marshall Space Flight Center to print the Panther combustor. Over the spring and summer of 2023, she put it through 31 hot-fires for a total duration of 200 seconds.

Data collected on these runs document the heat flux across the RDRE combustor, among other factors. Panther showcased its durability with runs as long as 15 seconds. “The water-cooled hardware would survive if we could continue feeding propellant to it,” Martinez says. “We could run it indefinitely.”

Just down the hall at Zucrow Labs building ZL3, Slabaugh is working on engines that don’t bring their oxidizer along for the ride. A missile traveling through the atmosphere can run an air-breathing engine – meaning it burns fuel with oxygen taken from its surroundings.

Carson Slabaugh is the Paula Feuer Associate Professor of Aeronautics and Astronautics, effective July 1, 2023. This is one of multiple new term-named professorships established this year through a generous gift from an AAE alumnus. (Purdue University photo).

“An air-breathing RDE has a different set of challenges because we’re stuck with the amount of pressure we can recover from the inlet. The air you push into the system is coupled to the vehicle’s ballistics,” Slabaugh says.

One of his students, Ethan Plaehn, has tackled the challenge of how many detonation waves propagate in an engine. That detail had been largely unpredictable before, even between multiple tests of the same engine at the same throttle setpoint.

“Ethan developed an RDE where we can actively change the engine flowpath geometry while it’s running. Before this development, we would witness a ‘cage match’ of sorts, where only the strongest waves would survive after ignition. Now, we can control this chaotic process and guide the system into one, two, three, or more waves,” Slabaugh says.

“Our goal is to achieve the maximum level of power density and thrust that we can, so this is a big deal. The number of waves can make a big difference. We’re very excited about this new understanding and having an effective control approach.”

You can now tour Zucrow Labs with 360-degree imagery! Explore the test cells, laser lab, control rooms and more. Visit tour.purdue.edu/zucrow.

In June 2022, NASA announced completion of a successful full-scale RDRE (rotating detonation rocket engine) test at Marshall Space Flight Center. The liquid-cooled, 3D-printed engine was fired more than a dozen times, totaling nearly 10 minutes in duration, and produced more than 4,000 pounds of thrust at full throttle. The average chamber pressure of 622 pounds per square inch is the highest rating for this design on record.

NASA named IN Space as its primary collaborator. The company is led by alumnus B.J. Austin (BSAAE ’99, MSAAE ’02), Purdue faculty members Steve Heister and Carson Slabaugh, and Zucrow Labs managing director Scott Meyer. This partnership is symbolic of the head start that Purdue researchers have on this type of propulsion.

“When we started this company, rotating detonation engines were in their infancy. There was no vision yet for a path to a flight system,” Heister says. “That changed in the last few years.”

But Slabaugh adds, academic research can only go so far.

“Purdue has an educational mission; our goal is student development. This technology has enough fundamental challenges to keep us busy for many years to come, but academic research will not get us all the way into a flight system,” Slabaugh says.