Sustainable Manufacturing

Summary

This part of research focuses on sustainable manufacturing, including energy-efficient process planning and scheduling, additive manufacturing and recycling pathways, disassembly and remanufacturing systems for end-of-life products, and the development of sustainable metalworking fluids.

Project

Quantifying Carbon Footprint in Industrial Heat Treatment Processes through Life Cycle Assessment

Funded by: Purdue Heat Treatment Consortium (PHTC)

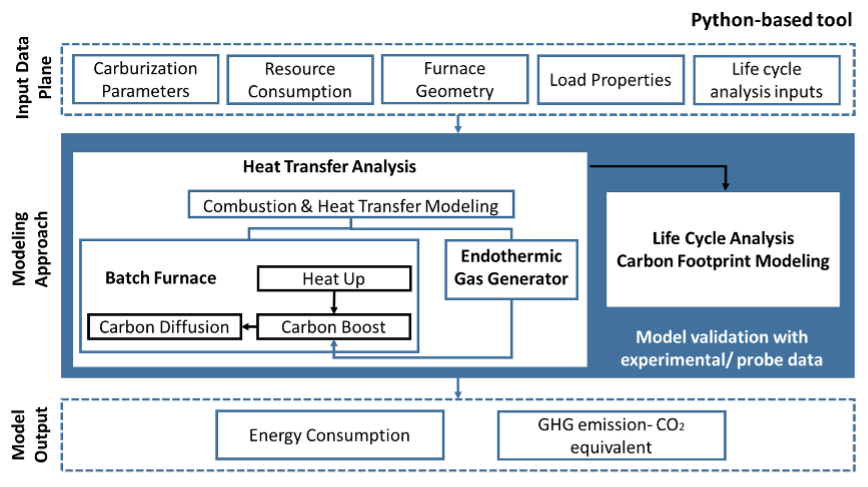

Introduction: This research targets decarbonization of industrial heat treatment, focusing on gas carburizing—a critical but energy-intensive process for hardening steel parts. A detailed Life Cycle Assessment framework quantifies Scope 1, 2, and 3 emissions, including natural gas use for heating and furnace atmosphere control. By modeling heat transfer and fuel consumption, the work identifies emissions hotspots and opportunities for energy efficiency and cleaner heating alternatives. Scope 1 emissions include flue gases from burning natural gas and endothermic gas production. Scope 2 and 3 indirect emissions are also quantified based on electricity use and upstream supply chain contributions. The goal is to guide industry toward significant emissions reductions and paving the way for more sustainable manufacturing.

Website: PHTC - Materials Engineering - Purdue University

Researchers involved: Lakshmi Srinivasan , Fu Zhao

Publications

Current state and emerging trends in advanced manufacturing: process technologies

K Raoufi, JW Sutherland, F Zhao, AF Clarens, JL Rickli, Z Fan, H Huang, ...

The International Journal of Advanced Manufacturing Technology 1-30, 2024

Current State and Emerging Trends in Advanced Manufacturing: Smart Systems

K Raoufi, K Haapala, J Sutherland, F Zhao, A Clarens, J Rickli, Z Fan, ...

Kamyar Raoufi, Karl Haapala, John Sutherland, Fu Zhao, Andres Clarens … 2024

Driving additive manufacturing towards circular economy: State-of-the-art and future research directions

J Zhao, Y Yang, MH Kobir, J Faludi, F Zhao

Journal of Manufacturing Processes 124, 621-637, 2024

Disassembly time estimation for used smartphones based on Maynard operation sequence technology

X Chu, L Li, F Zhao, JW Sutherland, F Yin

Computers & Industrial Engineering 110291, 2024

Chemical characterization of particulates and volatile organic compounds emitted during fused deposition modeling

TR Simon, F Zhao

Manufacturing Letters 35, 1284-1292, 2023

Comparative Life Cycle Assessment of Injection Molded and Big Area Additive Manufactured NdFeB Bonded Permanent Magnets

S Kulkarni, F Zhao, IC Nlebedim, R Fredette, MP Paranthaman

Journal of Manufacturing Science and Engineering 145 (5), 051001, 2023

Perspectives on future research directions in green manufacturing for discrete products

MJ Triebe, S Deng, JR Perez-Cardona, BG Joung, H Wu, N Shakelly, ...

Green Manufacturing Open 1 (IS-J 11,041), 2023

Disassembly sequence planning for target parts of end-of-life smartphones using Q-learning algorithm

Z Chen, L Li, F Zhao, JW Sutherland, F Yin

Procedia CIRP 116, 684-689, 2023

Integrating line balancing with network topology to support the planning of a remanufacturing system for electric vehicles

S Deng, T Maani, Y Yao, Y Yih, F Zhao, JW Sutherland

Procedia CIRP 116, 215-220, 2023

Exergy-based tool path evaluation method of material and energy flows to support the sustainable-oriented intelligent manufacturing

L Li, C Guo, J Yan, F Zhao, JW Sutherland

Proceedings of the Institution of Mechanical Engineers, Part C: Journal of … 2022

Modelling the effect of slide table mass on machine tool energy consumption: The role of lightweighting

MJ Triebe, F Zhao, JW Sutherland

Journal of Manufacturing Systems 62, 668-680, 2022

Development of a Cost Model for Vertical Milling Machines to Assess Impact of Lightweighting

MJ Triebe, F Zhao, JW Sutherland

Journal of Manufacturing and Materials Processing 5 (4), 129, 2021

Closing the material loop in additive manufacturing: A literature review on waste recycling

Y Yang, F Zhao

IOP Conference Series: Materials Science and Engineering 1196 (1), 2021

Understanding energy consumption of hydraulic press during drawing process

L Li, H Huang, F Zhao, X Zou, Y Ren, Z Liu, JW Sutherland

The International Journal of Advanced Manufacturing Technology 115, 1497-1516, 2020

Industrial sustainability: reviewing the past and envisioning the future

JW Sutherland, SJ Skerlos, KR Haapala, D Cooper, F Zhao, A Huang

Journal of Manufacturing Science and Engineering 142 (11), 110806, 2020

Special Issue on “Energy, Economy and Environment for Industrial Production Processes”

W Cai, G Tian, MC Zhou, F Zhao, J Cunha

Processes 8 (9), 1126, 2020

A multiobjective disassembly planning for value recovery and energy conservation from end-of-life products

Y Ren, H Jin, F Zhao, T Qu, L Meng, C Zhang, B Zhang, G Wang, ...

IEEE Transactions on Automation Science and Engineering 18 (2), 791-803, 2020

An efficient metaheuristics for a sequence-dependent disassembly planning

Y Ren, L Meng, C Zhang, F Zhao, U Saif, A Huang, GP Mendis, ...

Journal of Cleaner Production 245, 118644, 2020

Reusable unit process life cycle inventory for manufacturing: stereolithography

T Simon, Y Yang, WJ Lee, J Zhao, L Li, F Zhao

Production Engineering 13, 675-684, 2019

Variations of energy demand with process parameters in cylindrical drawing of stainless steel

L Li, H Huang, F Zhao, X Zou, Q Lu, Y Wang, Z Liu, JW Sutherland

Journal of Manufacturing Science and Engineering 141 (9), 2019

Topology optimization of oilstone components considering carbon emissions associated with honing processes

Q Lu, G Zhou, F Zhao, Y Ren, L Li, X Luan, JW Sutherland

Journal of Cleaner Production 225, 181-195, 2019

A three-stage method with efficient calculation for lot streaming flow-shop scheduling

H Wang, F Zhao, H Gao, JW Sutherland

Frontiers of Information Technology & Electronic Engineering 20 (7), 1002-1020, 2019

Characterizing the effect of process variables on energy consumption in end milling

L Zhou, F Li, F Zhao, J Li, JW Sutherland

The International Journal of Advanced Manufacturing Technology 101 (9-12), 2019

Reusable unit process life cycle inventory for manufacturing: gas metal arc welding

H Zhang, F Zhao

Production Engineering 13, 89-97, 2019

Modeling and analysis of the process energy for cylindrical drawing

L Li, H Huang, F Zhao, X Zou, GP Mendis, X Luan, Z Liu, JW Sutherland

Journal of Manufacturing Science and Engineering 141 (2), 021001, 2019

Determination of shape and distribution of abrasive grains to reduce carbon emissions of honing process

Q Lu, GH Zhou, F Zhao, L Li, YP Ren

Journal of Manufacturing Science and Engineering 141 (2), 021008, 2019

Achieving Energy Efficient Machine Tools by Mass Reduction through Multi-Objective Optimization

MJ Triebe, F Zhao, JW Sutherland

Procedia CIRP 80, 73-78, 2019

Power measurement in energy efficient manufacturing: Accuracy analysis, Challenges, and Perspectives for improvement

L Li, H Huang, F Zhao, M Gao, Z Liu, JW Sutherland

Procedia CIRP 80, 138-143, 2019

Optimal Joint Production and Emissions Reduction Strategies Considering Consumers’ Environmental Preferences: A Manufacturer’s Perspective

W Tong, J Du, F Zhao, D Mu, JW Sutherland

Sustainability 11 (2), 474, 2019

Understanding Energy Consumption in a Machine Tool through Energy Mapping

MJ Triebe, GP Mendis, F Zhao, JW Sutherland

Procedia CIRP 69, 259-264, 2018

An asynchronous parallel disassembly planning based on genetic algorithm

Y Ren, C Zhang, F Zhao, H Xiao, G Tian

European Journal of Operational Research 269 (2), 647-660, 2018

An MCDM-Based Multiobjective General Variable Neighborhood Search Approach for Disassembly Line Balancing Problem

Y Ren, C Zhang, F Zhao, MJ Triebe, L Meng

IEEE Transactions on Systems, Man, and Cybernetics: Systems 2018

Energy Efficient Manufacturing Process Planning

R Yin, F Zhao, F Zhao, JW Sutherland

Energy Efficient Manufacturing: Theory and Applications 339-358, 2018

Scheduling for Energy Efficient Manufacturing

NA Uhan, AL Liu, F Zhao

Energy Efficient Manufacturing: Theory and Applications 2018

Disassembly line balancing problem using interdependent weights-based multi-criteria decision making and 2-Optimal algorithm

Y Ren, C Zhang, F Zhao, G Tian, W Lin, L Meng, H Li

Journal of Cleaner Production 174, 1475-1486, 2018

Multi-objective optimization of tool path considering efficiency, energy-saving and carbon-emission for free-form surface milling

L Li, X Deng, J Zhao, F Zhao, JW Sutherland

Journal of Cleaner Production 172, 3311-3322, 2018

An Experimental Study on the Energy Consumption and Emission Profile of Fused Deposition Modeling Process

TR Simon, WJ Lee, BE Spurgeon, BE Boor, F Zhao

Procedia Manufacturing 26, 920-928, 2018

Trade-off analysis of tool wear, machining quality and energy efficiency of alloy cast iron milling process

X Luan, S Zhang, J Li, G Mendis, F Zhao, JW Sutherland

Procedia Manufacturing 26, 383-393, 2018

Research needs and recommendations on environmental implications of additive manufacturing

D Rejeski, F Zhao, Y Huang

Additive Manufacturing 19, 21-28, 2018

Product Redesign for Improved Value Recovery via Disassembly Bottleneck Identification and Removal

L Cong, F Zhao, JW Sutherland

Procedia CIRP 61, 81-86, 2017

An energy-saving method by balancing the load of operations for hydraulic press

L Li, H Huang, F Zhao, JW Sutherland, Z Liu

IEEE/ASME Transactions on Mechatronics 22 (6), 2673-2683, 2017

Analysis of a novel energy-efficient system with double-actuator for hydraulic press

L Li, H Huang, F Zhao, MJ Triebe, Z Liu

Mechatronics 47, 77-87, 2017

Operation scheduling of multi-hydraulic press system for energy consumption reduction

L Li, H Huang, F Zhao, Z Liu

Journal of Cleaner Production 165, 1407-1419, 2017

Dynamic Scheduling of a Semiconductor Production Line Based on a Composite Rule Set

Y Ma, F Qiao, F Zhao, JW Sutherland

Applied Sciences 7 (10), 1052, 2017

Selective cooperative disassembly planning based on multi-objective discrete artificial bee colony algorithm

Y Ren, G Tian, F Zhao, D Yu, C Zhang

Engineering Applications of Artificial Intelligence 64, 415-431, 2017

Value recovery from end-of-use products facilitated by automated dismantling planning

L Cong, F Zhao, JW Sutherland

Clean Technologies and Environmental Policy 19, 1867-1882, 2017

Characterization of particle emission from fuse deposition modeling printers

TR Simon, GA Aguilera, F Zhao

ASME 2017 12th International Manufacturing Science and Engineering …, 2017

Dynamic Manufacturing Scheduling Under Real-Time Electricity Pricing Based on MILP and ARIMA

Y Zhai, H Wang, F Zhao, JW Sutherland

International Manufacturing Science and Engineering Conference 50756 …, 2017

Integration of dismantling operations into a value recovery plan for circular economy

L Cong, F Zhao, JW Sutherland

Journal of Cleaner Production 149, 378-386, 2017

Scheduling of a single flow shop for minimal energy cost under real-time electricity pricing

H Zhang, F Zhao, JW Sutherland

Journal of Manufacturing Science and Engineering 139 (1), 014502, 2017

A comparative life cycle assessment (LCA) of lighting technologies for greenhouse crop production

H Zhang, J Burr, F Zhao

Journal of Cleaner Production 140, 705-713, 2017

An energy-saving method to solve the mismatch between installed and demanded power in hydraulic press

L Li, H Huang, Z Liu, X Li, MJ Triebe, F Zhao

Journal of Cleaner Production 139, 636-645, 2016

A multi-level optimization approach for energy-efficient flexible flow shop scheduling

J Yan, L Li, F Zhao, F Zhang, Q Zhao

Journal of Cleaner Production 137, 1543-1552, 2016

A coordinate method applied to partitioned energy-saving control for grouped hydraulic presses

L Li, H Huang, F Zhao, Z Liu

Journal of Manufacturing Systems 41, 102-110, 2016

A Method to Optimize Value Recovery From End-of-Life Products

L Cong, F Zhao, JW Sutherland

ASME 2016 11th International Manufacturing Science and Engineering …, 2016

Scheduling on a single machine under time-of-use electricity tariffs

K Fang, NA Uhan, F Zhao, JW Sutherland

Annals of Operations Research 238 (1), 199-227, 2016

Manufacturing Scheduling of Collaborative Factories for Energy Cost Reduction

H Zhang, F Zhao, JW Sutherland

Procedia Manufacturing 1, 122-133, 2015

Econological scheduling of a manufacturing enterprise operating under a time-of-use electricity tariff

A Sharma, F Zhao, JW Sutherland

Journal of Cleaner Production 108, 256-270, 2015

Environmentally Friendly Machining 29

F Zhao, A Sharma

Energy-efficient scheduling of multiple manufacturing factories under real-time electricity pricing

H Zhang, F Zhao, JW Sutherland

CIRP Annals 64 (1), 41-44, 2015

Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis

JM Wilson, C Piya, YC Shin, F Zhao, K Ramani

Journal of Cleaner Production 80, 170-178, 2014

Prioritizing design for environment strategies using a stochastic analytic hierarchy process

D Ramanujan, WZ Bernstein, JK Choi, M Koho, F Zhao, K Ramani

Journal of Mechanical Design 136 (7), 071002, 2014

Energy-conscious flow shop scheduling under time-of-use electricity tariffs

H Zhang, F Zhao, K Fang, JW Sutherland

CIRP Annals 63 (1), 37-40, 2014

Sustainable Systems and Technologies, v2 (2014)

F Zhao, A Lagro, G Mendis, C Handwerker,

Environmentally Friendly Machining

F Zhao, A Sharma

Springer 2014

A review of engineering research in sustainable manufacturing

KR Haapala, F Zhao, J Camelio, JW Sutherland, SJ Skerlos, DA Dornfeld, ...

Journal of Manufacturing Science and Engineering 135 (4), 041013, 2013

Flow shop scheduling with peak power consumption constraints

K Fang, NA Uhan, F Zhao, JW Sutherland

Annals of Operations Research 206, 115-145, 2013

Unit Process Life Cycle Inventory Models of Hot Forming Processes

JJ Buis, JW Sutherland, F Zhao

ASME 2013 International Manufacturing Science and Engineering Conference …, 2013

Life cycle analysis of grinding: a case study of non-cylindrical computer numerical control grinding via a unit-process life cycle inventory approach

VR Murray, F Zhao, JW Sutherland

Proceedings of the Institution of Mechanical Engineers, Part B: Journal of … 2012

Toward the development of process plans with reduced environmental impacts

F Zhao, VR Murray, K Ramani, JW Sutherland

Frontiers of Mechanical Engineering 7, 231-246, 2012

Quantifying the water inventory of machining processes

F Zhao, J Ogaldez, JW Sutherland

CIRP Annals 61 (1), 67-70, 2012

Water footprint quantification of machining processes

J Ogaldez, A Barker, F Zhao, JW Sutherland

Leveraging Technology for a Sustainable World: Proceedings of the 19th CIRP …, 2012

A new approach to scheduling in manufacturing for power consumption and carbon footprint reduction

K Fang, N Uhan, F Zhao, JW Sutherland

Journal of Manufacturing Systems 30 (4), 234-240, 2011

Laser-based remanufacturing of engineering components and its environmental impact analysis

JM Wilson, C Piya, V Murray, Y Shin, F Zhao, K Ramani

International Congress on Applications of Lasers & Electro-Optics 2011 (1 …, 2011

Flow shop scheduling for sustainable manufacturing

K Fang, NA Uhan, F Zhao, JW Sutherland

Maxim Sviridenko, IBM Watson Research Center Steef van de Velde, Erasmus … 2011

A review of engineering research in sustainable manufacturing

KR Haapala, F Zhao, J Camelio, JW Sutherland, SJ Skerlos, DA Dornfeld, ...

ASME 2011 International Manufacturing Science and Engineering Conference …, 2011

A new shop scheduling approach in support of sustainable manufacturing

K Fang, N Uhan, F Zhao, JW Sutherland

Glocalized Solutions for Sustainability in Manufacturing: Proceedings of the … 2011

Environmental assessment of laser assisted manufacturing: case studies on laser shock peening and laser assisted turning

F Zhao, WZ Bernstein, G Naik, GJ Cheng

Journal of Cleaner Production 18 (13), 1311-1319, 2010

Environmental Sustainability of Laser-Based Manufacturing: Case Studies on Laser Shock Peening and Laser Assisted Turning

F Zhao, G Naik, L Zhang

ASME 2009 International Manufacturing Science and Engineering Conference, 2010

Evaluation of cooling potential and tool life in turning using metalworking fluids delivered in supercritical carbon dioxide

AF Clarens, YE Park, J Temme, K Hayes, F Zhao, S Skerlos

ASME 2009 International Manufacturing Science and Engineering Conference, 2010

Development of Sustainable Metalworking Fluid Systems

F Zhao

Current advances in sustainable metalworking fluids research

SJ Skerlos, KF Hayes, AF Clarens, F Zhao

International Journal of Sustainable Manufacturing 1 (1-2), 180-202, 2008

Optimization of metalworking fluid microemulsion surfactant concentrations for microfiltration recycling

F Zhao, A Clarens, SJ Skerlos

Environmental Science & Technology 41 (3), 1016-1023, 2007

Structural aspects of surfactant selection for the design of vegetable oil semi-synthetic metalworking fluids

F Zhao, A Clarens, A Murphree, K Hayes, SJ Skerlos

Environmental Science & Technology 40 (24), 7930-7937, 2006

Design of Microfiltration Compatible Metalworking Fluids for Recycling

F Zhao, AF Clarens, SJ Skerlos

Industrial Ecology for a Sustainable Future 2005

Microfiltration recycling of semi-synthetic metalworking fluids: modeling and formulation design

F Zhao

University of Michigan. 2005

Modeling of porous filter permeability via image-based Stochastic reconstruction of spatial porosity correlations

F Zhao, HR Landis, SJ Skerlos

Environmental Science & Technology 39 (1), 239-247, 2005

Mechanistic Model of Coaxial Microfiltration for Semi-Synthetic Metalworking Fluid Microemulsions

F Zhao, M Urbance, SJ Skerlos

Journal of Manufacturing Science and Engineering 126 (3), 435-444, 2004

Ecological Material and Green Manufacturing: Design and Technology for Metalworking Fluid Systems

SJ Skerlos, P Adriaens, K Hayes, J Zimmerman, F Zhao

Proceedings of the World Engineering Congress 2004

Expeditious identification and quantification of mycobacteria species in metalworking fluids using peptide nucleic acid probes

SJ Skerlos, LA Skerlos, CA Aguilar, F Zhao

Journal of Manufacturing Systems 22 (2), 136-147, 2003

Economic and environmental characteristics of global cellular telephone remanufacturing

SJ Skerlos, WR Morrow, K Chan, F Zhao, A Hula, G Seliger, B Basdere, ...

IEEE International Symposium on Electronics and the Environment 2003

Economic considerations in the implementation of microfiltration for metalworking fluid biological control

SJ Skerlos, F Zhao

Journal of Manufacturing Systems 22 (3), 202-219, 2003

Challenges to achieving sustainable aqueous systems: a case study in metalworking fluids

SJ Skerlos, P Adriaens, K Hayes, A Rihana, K Kurabayashi, S Takayama, ...

Proceedings Second International Symposium on Environmentally Conscious … 2001