The NCSC staff and facilities are available to conduct, participate in or assist in testing for research, experimental or pilot projects. The NCSC is available as a third-party laboratory if needed to verify results or assist in dispute resolution. Please check with the NCSC to determine costs. Please call the NCSC to discuss the specifics of your research project.

The NCSC is equipped with all of the required Superpave binder and mixture testing equipment:The NCSC has access to the following:Bending Beam Rheometer (BBR) -- ASTM D6648/AASHTO T313 Dynamic Shear Rheometer (DSR) -- AASHTO T315 Direct Tension Tester (DTT) -- ASTM D6723/AASHTO T314 Brookfield Viscometer -- ASTM D4402/AASHTO T316 Circular Texture Meter (CTM) -- ASTM E2157 Dynamic Friction Tester (DFT) -- ASTM E1911 Rolling Thin Film Oven (RTFO) -- ASTM D2872/AASHTO T240 Pressure Aging Vessel (PAV) -- ASTM D6521/AASHTO R28 Superpave Gyratory Compactor (SGC) -- ASTM D6925/AASHTO T312 Aggregate Gradation -- ASTM C136/AASHTO T27 Aggregate Specific Gravity -- ASTM C127 and C128/AASHTO T84 and T85 Aggregate Consensus Properties -- ASTM C1252 and D4791/AASHTO T326

Binder EquipmentBinder Ignition Oven -- AASHTO T308 Lab Permeability of HMA Samples -- AASHTO PS129 Superpave Performance Testing Equipment Conventional Asphalt Cement Testing Equipment Binder Extraction/Recovery -- ASTM D6847 and D1856/AASHTO T319 and T170 Accelerated Pavement Testing Facility (APT)

|

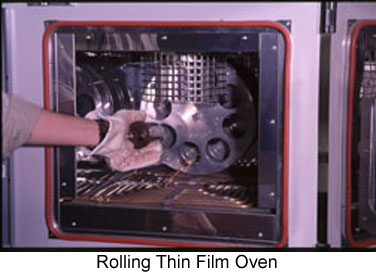

Rolling Thin Film Oven (RTFO)

Binder aging, during mix production and construction is simulated by aging the binder in an RTFO. This test exposes films of binder to heat and air and simulates the binder age hardening that occurs when hot mix asphalt is produced in an asphalt plant. Binder flows around inside the RTFO bottles as the carriage rotates, exposing the thin film of asphalt binder to heat and air. |

Pressure Aging Vessel (PAV)

Binder aging that occurs during the service life of the pavement is simulated by use of a PAV. This test exposes binder samples to heat and pressure in order to simulate, in a matter of hours, years of in-service aging in a pavement. This aging process follows short-term aging in the RTFO.

Dynamic Shear Rheometer (DSR)The DSR is used to characterize the viscous and elastic behavior of asphalt binders. This is done by measuring the complex shear modulus (|G*|) and phase angle (δ) of asphalt binders. |G*| is a measure of the total resistance of a material to deformation when it is sheared repeatedly. It consists of two parts; a part that is elastic (recoverable) and a part that is viscous (non-recoverable). δ is an indicator of the relative amounts of recoverable and non-recoverable deformation.

|

Bending Beam Rheometer (BBR)

The BBR is used to assess asphalt binder stiffness at very low temperatures. The test uses engineering, elastic beam theory to measure the stiffness of a small asphalt beam sample under a creep load. A creep load is used to simulate the stresses that gradually build up in a pavement when temperature drops. Two parameters are evaluated with the BBR; creep stiffness, which is a measure of how the asphalt resists constant loading and m-value, which is a measure of how the asphalt stiffness changes as loads are applied. |

Direct Tension Tester (DTT)

The direct tension test measures the failure stress (σf) and strain (εf) of asphalt binders at low temperature. The test is performed at temperatures ranging from 0°C to -24°C, the temperature range within which binders exhibit brittle behavior. Furthermore, the test is performed on binders that have been aged in a RTFO and PAV. Consequently, the test measures the performance characteristics of binders as if they had been exposed to hot mixing process in a plant facility and some in-service aging.

Rotational ViscometerRotational viscosity is used to evaluate high temperature workability of binders. High temperature binder viscosity is measured to ensure that the asphalt is sufficiently fluid when pumping and mixing. This, in turn, will facilitate that the proper coating of the aggregate particles with the heated binder. A rotational coaxial cylinder viscometer, such as the Brookfield apparatus, is used rather than a capillary viscometer. Some asphalt technologists refer to this measure as "Brookfield Viscosity". This method of measuring viscosity is detailed in ASTM D4402, "Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer".

Mix Design Equipment

Superpave Gyratory Compactor (SGC)

The SGC is a transportable device whose primary function is to fabricate test specimens by simulating the effect of traffic on an asphalt pavement. The specimens fabricated with the gyratory compactor are used to determine the volumetric properties (air voids, voids in the mineral aggregate, and voids filled with asphalt) of Superpave mixes and for mechanical testing. Data collected during the compaction process allow determination of the amount of densification versus number of gyrations and assessment of the compactibility of the mixture. By kneading mixes to simulate construction compaction, the Superpave gyratory compactor provides specimens that are representative of actual in-service pavements. The level or amount of compaction is dependent on the environmental conditions and traffic levels expected at the job site.