Laser, electric fields combined for new 'lab-on-chip' technologies

Laser, electric fields combined for new 'lab-on-chip' technologies

| Author: | Emil Venere |

|---|---|

| Magazine Section: | Innovate |

| College or School: | CoE |

| Article Type: | Issue Feature |

| Page CSS: | .sidebar.right {

top: -1200px; } |

| Feature Intro: | Three recent mechanical engineering doctoral graduates are playing major roles in developing innovative technologies in diverse areas from food safety to crime-scene forensics. |

The technologies are ideal for "lab-on-a-chip" applications, or miniature instruments that perform functions normally requiring large laboratory equipment, says Steven T. Wereley, professor of mechanical engineering.

The method, called "hybrid optoelectric manipulation in microfluidics," uses lasers and electric fields to manipulate fluids and tiny particles such as bacteria, viruses and DNA.

Recent graduate Aloke Kumar, a Wigner Fellow and staff member at Oak Ridge National Laboratory, says, "This is a cutting-edge technology that has developed over the last decade from research at a handful of universities."

He was lead author of an article about the technology that was featured in July on the cover of Lab on a Chip magazine, published by the Royal Society of Chemistry. The piece was flagged by the publication as a hot article and has been made free to access at http://blogs.rsc.org/lc/2011/06/15/issue-13-now-online/.

Writing the article were Kumar; Wereley; Stuart J. Williams, assistant professor of mechanical engineering at the University of Louisville; Han-Sheng Chuang, assistant professor in the Department of Biomedical Engineering at National Cheng Kung University in Taiwan; and Nicolas G. Green, a researcher at the University of Southampton, U.K.

Like Kumar, Williams and Chuang were doctoral students under Wereley and are recent graduates.

These were among my best three students ever, Wereley says.

Much of the research has been based at Birck Nanotechnology Center at Purdues Discovery Park.

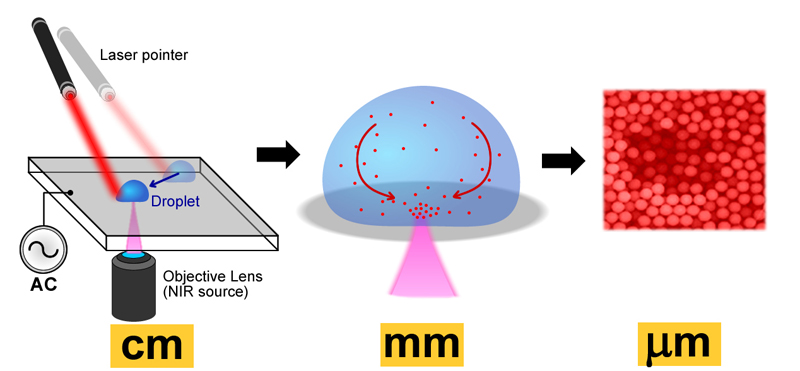

Because the technology makes it possible to manipulate objects across a huge size range -- from the macroscale to the nanoscale -- it has the potential for broad future impact, Kumar says.

We can manipulate not only big-sized objects like droplets but also tiny DNA molecules inside droplets by using one combined technique, he says. This can greatly enhance the efficiency of lab-on-a-chip sensors.

Williams says the technology is ready for some applications, including medical diagnostics and analyzing environmental samples.

There are two main thrusts in applications, he says. The first is micro- and nanomanufacturing and the second is lab-on-a-chip sensors. The latter has demonstrated biologically relevant applications in the past couple of years, and its expansion in this field is immediate and ongoing.

The technology works by first using a red laser to position a droplet on a platform specially fabricated at Purdue. Next, a highly focused infrared laser is used to heat the droplets, and then electric fields cause the heated liquid to circulate in a microfluidic vortex. This vortex is used to isolate specific types of particles in the circulating liquid, like a micro centrifuge. Particle concentrations assume the size, location and shape of the infrared laser pattern.

This works very fast, Wereley says. It takes less than a second for particles to respond and get pulled out of solution.

Systems using the hybrid optoelectric approach can be designed to precisely detect, manipulate and screen certain types of bacteria, including particular strains that render heavy metals less toxic.

We are shooting for biological applications, such as groundwater remediation, Wereley says. Even within the same strain of bacteria some are good at the task and some are not, and this technology makes it possible to efficiently cull those bacteria from others. The bacteria could be injected into the contaminated ground. You seed the ground with the bacteria, but first you need to find an economical way to separate it.

Purdue researchers also are pursuing the technology for pharmaceutical manufacturing, he says.

These types of technology are good at being very dynamic, which means you can decide in real time to grab all particles of one size or one type and put them somewhere, Wereley says. This is important for the field of pharmacy because a number of drugs are manufactured from solid particles suspended in liquid. The particles have to be collected and separated from the liquid.

This process is now done using filters and centrifuges.

A centrifuge does the same sort of thing but its global, it creates a force on every particle, whereas this new technology can specifically isolate only certain particles, Wereley says. We can, say, collect all the particles that are one micron in diameter or get rid of anything bigger than two microns, so you can dynamically select which particles you want to keep.

The technology also may be used as a tool for nanomanufacturing by assembling suspended particles, called colloids. The ability to construct objects with colloids makes it possible to create structures with particular mechanical and thermal characteristics for electronic devices and tiny mechanical parts. The nanomanufacturing applications are at least five years away, Williams says.

Another potential application is as a tool for learning about fundamental electrokinetic forces of molecules and biological structures, which is difficult to do with existing technologies.

Thus there are very fundamental science applications of these technologies as well, Kumar says.

Related Links:

Steven T. Wereley: http://engineering.purdue.edu/~wereley

Lab on a Chip magazine: http://blogs.rsc.org/lc/

Lab on a Chip on Twitter: http://twitter.com/LabonaChip

Comments