Creating soft machines Digital fabrication lab led by Rebecca Kramer is developing new methodologies that embed control at the material level

Creating soft machines

| Author: | William Meiners and Emil Venere |

|---|---|

| Subtitle: | Digital fabrication lab led by Rebecca Kramer is developing new methodologies that embed control at the material level |

| Magazine Section: | New Faculty Profile |

| Article Type: | Feature |

| Feature CSS: | background-position: 50% 60%; |

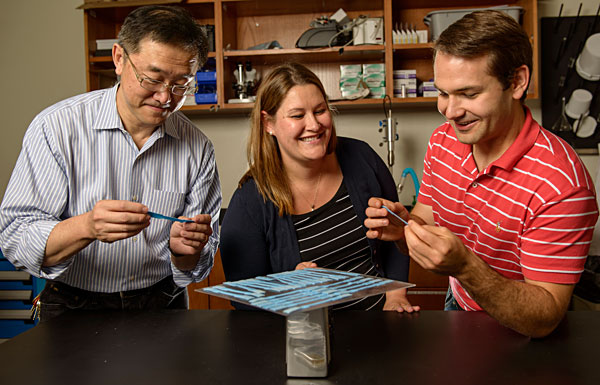

Rebecca Kramer, assistant professor of mechanical engineering, is one of seven U.S. researchers selected for a NASA Early Career Faculty Space Tech Research grant. The NASA award recognizes the potential of young faculty who are conducting transformative research applicable to space technology.

Kramer and her research team are developing a robotic fabric that moves and contracts and is embedded with sensors — an approach that could bring active clothing and a new class of soft robots. Such an elastic technology could enable development of robots that have sensory skin, stretchable robotic garments that people might wear for added strength and endurance, g-suits for pilots or astronauts to counteract the effects of acceleration, and lightweight, versatile robots to roam alien landscapes during space missions.

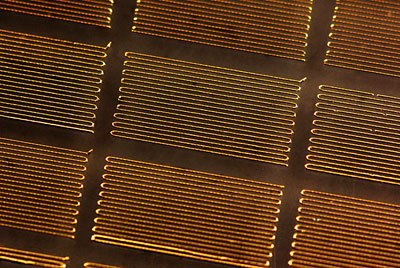

The robotic fabric is a cotton material containing sensors made of a flexible polymer and threadlike strands of a shape-memory alloy that return to a coiled shape when heated, causing the fabric to move.

“We have integrated actuation and sensing, whereas most robotic fabrics currently in development feature only sensing or other electronic components that utilize conductive thread,” Kramer says. “We also use standard sewing techniques to introduce the thread-like actuators and sensors into the fabric, so they could conceivably be integrated into the existing textile manufacturing infrastructure.”

The robotic fabric can be wrapped around a block of foam or an inflated balloon. Orienting the fabric in one direction causes the robot to bend, producing locomotion similar to that of an inchworm. Orienting the fabric in a different direction causes it to compress — producing a peristaltic, or slithering, locomotion.

Findings are detailed in a research paper, authored by doctoral students Michelle Yuen, Arun Cherian, Jennifer Case and Justin Seipel; and Kramer, that was presented during the International Conference on Intelligent Robots and Systems on Sept. 14-18 in Chicago.

Applications for space and beyond

The paper is related to research she is leading in development of active elastic skins for soft robotics, where all the functional elements are embedded in a stretchable skin. This skin will include flexible electronics that are less sensitive to vibration than conventional hardware, making them rugged enough for space missions. Such a technology could allow space travelers to ship lightweight, easy-to-store sheets of robotic skin for assembly once they reach their destination. Like the robotic fabric, the skin might be wrapped around a deformable object, creating robots capable of exploring alien terrains.

“We will be able to design robots on-the-fly,” Kramer says. “Anything can be a robot because all of the robotic technology is in the fabric or skin.”

Kramer is also collaborating internationally with researchers on “variable stiffness” fabric, where integrated fibers including a shape-memory polymer allow the fabric to have changing stiffness. When heated, the polymer softens; when cooled, the polymer stiffens. This variable stiffness polymer is coated onto thin heating wires in order to precisely control the stiffness of the overall fiber. Such a fabric could be used in medical braces that lock in place for support. The approach represents a potential energy-efficient technology for robotics. “Ordinarily, if we are moving a hinge joint and want to maintain a particular position, we would have to maintain a high energy input to keep the joint from relaxing,” Kramer says. “Here, we could just lock it in place.”

Visit Prof. Kramer's lab website, The Faboratory.