College of Engineering Honors Program invests in LEGO kits to improve student in-course projects

In spring 2024, the College of Engineering utilized a $100,000 innovation grant to invest in new project kits including customized SPIKE education sets for Engineering Honors Program students. The partnership ushered in a unique opportunity: avenues for new projects and skill development that wasn't possible prior.

A dense jungle. A collapsed building. Fiery terrain.

It was up to Purdue University students in the College of Engineering Honors Program (EHP) to navigate these with a motorized robot comprised of LEGO set pieces, bricks and sensors in their final demonstration.

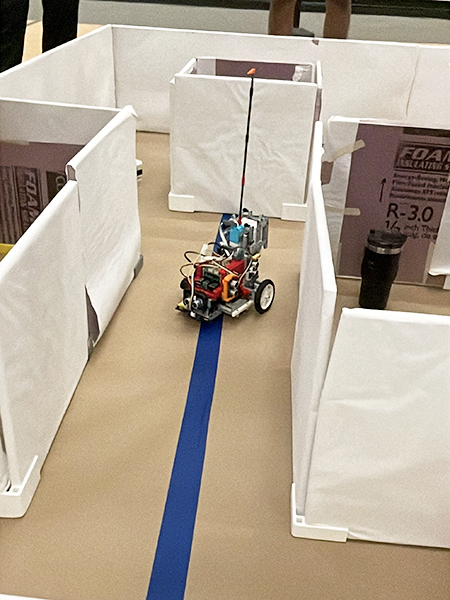

Or, at least, in imagination. The Honors Introduction to Innovation and the Physical Science of Engineering Design II (ENGR 16200) course’s obstacles for the spring 2025 semester were foam maze walls, paper floors, large magnets and infrared devices. But the idea of natural disaster navigation was still present in the overarching objectives: navigate the maze, collect data to create a map another robot can replicate, deliver cargo without breaking it at the end of the maze and do all of this while maintaining a nonthreatening and helpful appearance through symbols (like stickers of medicine or water) and movements.

It's a series of challenging objectives, all happening at once. It’s not too tough for students in EHP, though. Challenge is par for the course.

“In this course, our expectations are that students go above and beyond,” said Timothy Whalen, associate director of EHP.

EHP is full of high-achieving students in engineering who have an intense desire to expand their education into multidisciplinary and global experiences. Students can embrace engaging and rigorous academics, which include two semesters of engineering design, teamwork, data collection and in-person presentations.

As a bonus for the first-year students in ENGR 16200, all equipment was new, from computer parts to sensors.

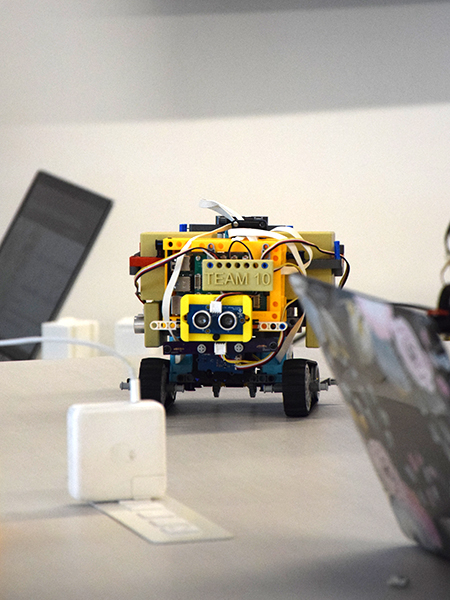

In spring 2024, the College of Engineering utilized a $100,000 innovation grant to invest in new project kits including customized SPIKE education sets for EHP students. Each kit is comprised of motors, sensors and coding software to communicate with included sensors and motors. Funds were also used to purchase new single-board computers, called Raspberry Pi 4s, to respond to coding input and sensors to move the LEGO motors. The upgrade is a culmination of a two-year partnership.

“We took aproactive approachto seeking out the partnership with Lego Education and collaborating to co-design project kits with new features and capabilities for sensing and programming,” wrote Jaqueline Linnes, director of EHP and Marta E. Gross Associate Professor of Biomedical Engineering. “We invited representatives to watch the fall 2023 demonstrations done with previous kits. They came away impressed by both the strong technical abilities of the students and the exciting ways they were using the electronics, solidifying the company’s desire to support our program further.”

The partnership ushered in a unique opportunity for first-year engineering Honors students: avenues for new projects and skill development that wasn’t possible prior.

Students began working with the LEGO kits in the fall 2024 in ENGR 16100, Honors Introduction to Innovation and the Physical Science of Engineering Design I.

“In the fall, we asked students to design a machine for us,” Whalen said. “It always goes badly, and that’s because it’s supposed to go badly. The machines they make might not work, or if they do, the students didn’t document what they did so it can be repeated. They learn that design includes more than the end product: It’s a multi-faceted concept.

“This semester, students are learning that design is a thought process. It’s very easy for a student, when they're designing, to think of the best-case scenario. This project is the culmination of them really thinking about design from all aspects, not just the ideal.”

Students regularly dealt with code mix-ups and motor malfunctions while preparing to juggle maze navigation, three data-collecting sensors, holding cargo and finding ways to display the cargo’s contents that were universally understood. For Ashwina Agarwal, a first-year student, making the colorful, LEGO brick-made machine register the surroundings proved the most challenging part.

“We were trying to get the robot to understand when it escaped the maze,” Agarwal, from New Jersey, said. “We programmed it to turn left and right to make sure that there were no walls and after a lot of trial and error, it actually did that. It was a great celebratory moment of three months of our work.”

The coding required to navigate motors and sensors, especially in real time perceiving an obstacle — the foam maze wall or a magnet in its path — or a “fire,” simulated by an infrared base, was new to Agarwal. So was statistics.

“I didn’t really think I’d ever use statistics,” she said. “But it's essential to analyzing the robot's success, and it helped determine the project's outcome. We always need data, and we need to know how to analyze it. It’s how we made our decisions and determined if our devices actually worked.”

Teamwork proved to be one of the most essential components for the five sections of first-year students. Split into teams of four, each group delegated tasks and regularly communicated ideas, pitfalls and workarounds in the building sessions and on the demo floor on April 28, 2025.

Each team navigated one of eight complex mazes with varied hazards. Robots surprised the teams by turning in full circles instead of turning left, running into and through maze walls, and, occasionally, by working with minimal intervention. With three minutes to calibrate and 18 minutes to successfully complete every task, teams programed, reprogrammed and cheered on their robot as the judges — graduates of the course — took notes and kept time.

When a team’s device — made with colorful bricks and often adorned with a smiley face to make it seem friendly — rolled its way through each checkpoint and out of the maze, the breath of relief that teams took was often audible.

The data each robot gathered on the course was presented on April 30 to teams of peers. Every team had a wide array of successes, failures and insights for future builds and programs, from coding commands to future cultural awareness. In a presentation of its findings, one team noted that, while many teams included images of band-aids to denote medical supplies in a cargo drop, band-aids are almost exclusively an American product. They had discovered that point through surveying friends, family and peers when creating the icons that would attach to their cargo. It was information they wouldn’t have discovered otherwise.

“This has taught me a lot of basics in engineering and how it can be so interdisciplinary,” said Agarwal. “I knew what I wanted to major in, but I wasn’t aware of all the pathways I could take. Through this class, I've learned that you can really contribute to anything, anywhere, with engineering.”