Research:

Solid mechanics applied to the multi-scale analysis and design of

advanced and novel architectured materials, interfaces and complex

structures. Our research interests lie at the interface between Solid

Mechanics and Materials Engineering with focus on the development of

novel materials that exhibit paradigm-shifting properties for various

applications that can impact the general field of infrastructure and

lightweight structural materials. Our contribution to solid mechanics

has been focused on the structure-function relationship of advanced

materials at multiple length-scales, combining state-of-the-art

computational techniques and experiments to characterize the

properties, and enabling the design of novel materials. Our arly work

on micromechanical models for materials has provided a robust framework

for combined computational/experimental investigations of

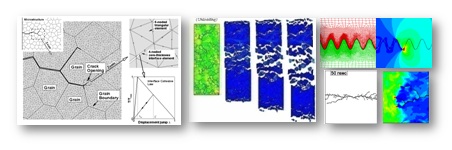

polycrystalline materials. Our contribution to fracture mechanics

includes the development of a new fracture models for thin-walled

structures and their implementation in commercial finite element codes.

We also made contributions in the area of smart materials, structures

and smart composites (with a total of 10 patents and 5 other published

patent applications). We have recently worked on solid mechanics

problems related to biological and biomimetic materials. Our group

pioneered the use of the 3D printing technology for the fabrication of

scaled-up biomimetic composites and its combination with

theoretical/computational models and experiments to unveil the most

important toughening mechanisms found in some of most impact resistant

natural materials. Our most recent work has focused on architectured

metamaterials, smart and programmable materials. See below some

examples and related papers.

For a more complete list of publications click [here]

Watch some videos related to our research:

Selected Research Projects

- Convergent Evolution To Engineering: Multiscale Structures

And Mechanics In Damage Tolerant Functional Bio-Composite And

Biomimetic Materials - DoD/MURI 2015-2018.

- CAREER: "Multiscale Investigation and Mimicry of

Naturally-Occurring Ultra-High Performance Composite Materials," NSF

Faculty Early Career Development 2013-2018.

- Phase Transforming Cellular Materials, NSF-Goali, 2015-2018.

- A Multiscale Strategy for the Modeling of the mechanical

performance of hoop and loop fasteners based on a detachment zone model

(DZM). Velcro Co. 2013-2016.

- Collaborative Research: 3D Printing of Civil Infrastructure

Material with Controlled Microstructural Architectures, NSF, 2016-2019.

- Scalable Nanomanufacturing. SNM: Roll-To-Roll Manufacturing

Of Films And Laminates Based On Cellulose Nanomaterials, NSF, 2014-2018.

- Concrete Patching Materials And Techniques An Guidelines For Hot Weather Concreting INDOT/JTRP, 2014-2016.

- Investigating The Need For Hma Drainage Layers INDOT/JTRP2015-2016.

- Toward Performance Related Specifications for Concrete Pavements INDOT/JTRP, 2014-2016.

- Damage-tolerant Biological Composites Derived from the Teeth of a Giant Chiton AFOSR 2012-2017.

- Uncovering and Validating Toughening Mechanisms in High Performance Composites, AFOSR 2012-2016.

Related Projects:

|

|

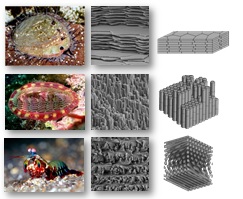

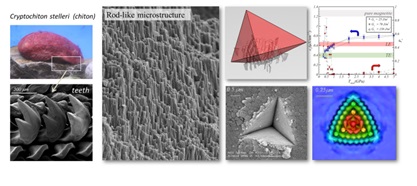

Biological and biomimetic

materials research:

Identification of

deformation and failure mechanisms of the

hierarchical structure of hard biological materials through different

length scale, with emphasis on biomineralized marine organisms such as

mollusk shells, radular teeth and crustaceans exoskeletons.

Biomimetics applied to the intelligent design of materials: Design and

modeling of synthetic nano/micro-composites mimicking hard biological

materials using bioinspired damage mitigation strategies. Development

of multiscale models for bio-inspired materials. Strong collaboration

with material scientists, chemists and biologists.

Our group is

currently focused on two remarkable hard biological materials, the

chiton’s radular

teeth and nacre. (Current work is being done in collaboration with Prof. David Kisailus' group at UC Riverside.)

|

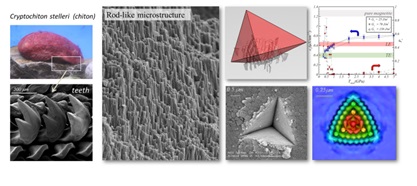

The radular teeth of chitons, a group of elongated mollusks

that are able to erode hard substrates, has a remarkable damage

tolerance and

abrasion resistance properties. Its rod-like structured made

of of magnetite

grains, is shown to exhibit remarkable hardness and stiffness

(even harder than human enamel).

The second material is nacre,

found in certain sea shells, an excellent

example of material design and optimization for extreme strength and toughness. Although this

materials is constituted by 95% of a brittle ceramic (CaCO3), it exhibits a remarkable

toughness without sacrificing strength. In

fact, nacre is 3000 times tougher than its constituent ceramic material.

|

MURI Project: Our lab is part of a multi-university and multi- disciplinary (MURI) team "Convergent

Evolution to Engineering: Multiscale Structures and mechanics in Damage

Tolerant Functional Bio-Composite and Biomimetic Maetrials".

Awarded by the Department of Defense ($7.5M) this project will

study over 20 organisms, including mammals, reptiles, birds,

fish, mollusks, crustaceans, fosils, insects and plants to

develop strong, tough materials based on their design structures. Press

Release [@Purdue] [@UCR]

website: http://muri.ucr.edu

Collaborators: David Kisailus, Cheryl Hayashi (University of California Riverside), Joanna McKittrick, Marc Meyers (University of California San Diego), Horacio Espinosa (Northwestern University) and Robert Ritchie (University of California Berkeley).

Most relevant Papers:

Abalone/Nacre:

- F. Barthelat, H. Tang, P.D. Zavattieri, C-M. Li and H.D. Espinosa, ”On

the mechanics of mother-of-pearl: A key feature in the material

hierarchical structure”, Journal of the Mechanics and

Physics of Solids, 55(2), pp. 306-337, 2007 (Top 10 Most Cited

Journal of the Mechanics and Physics of Solids Article during the last

5 years). . [Download

PDF]

- J.E. Rim, P.

Zavattieri, A. Juster, H. Espinosa, “Dimensional

analysis and parametric studies for designing artificial nacre”,

Journal of the

Mechanical Behavior of Biomedical Materials, 4(2), pp.

190-211, 2011. [Download

PDF]

- H. Espinosa,

A.

Juster, F. Latourte, D. Gregoire, O. Loh, P.

Zavattieri, “

Tablet-Level Origin of Toughening in Abalone Shells and Translation to

Synthetic Composite Materials

”, Nature Communications, 2,

173, doi:a10.1038/ncomms1172 , 2011.

[Download PDF]

Mantis Shrimp:

- James C.

Weaver, Garrett W. Milliron, Ali Miserez, Kenneth

Evans-Lutterodt, Steven Herrera, Isaias Gallana, William J. Mershon,

Brook Swanson, Pablo Zavattieri, Elaine DiMasi, and David Kisailus, "The Stomatopod Dactyl Club: A

Formidable Damage-Tolerant Biological Hammer", Science, 336

(no. 6086), pp.

1275-1280, June 2012.

[Download PDF].

- L.K.

Grunenfelder, N. Suksangpanya, C. Salinas, G. Milliron, N. Yaraghi, S.

Herrera, K. Evans-Lutterodt, S.R. Nutt, P. Zavattieri, D. Kisailus,“Bio-Inspired Impact Resistant Composites", Acta Biomaterialia, 10(9), pp. 3997-4008, 2014. (DOI: 10.1016/j.actbio.2014.03.022) [Download PDF]

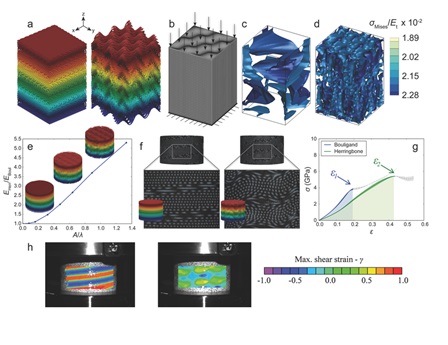

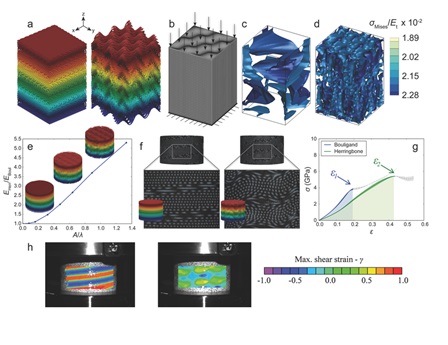

- N. Guarín-Zapata, J.D. Gomez, N. Yaraghi, D. Kisailus, P.D. Zavattieri, "Shear Wave Filtering in Naturally-Occurring Bouligand Structures", Acta Biomaterialia, 23, pp. 11-20, 2015.23, pp. 11-20, 2015. [Download PDF]

- Yaraghi, N. A., Guarín-Zapata,

N., Grunenfelder, L. K., Hintsala, E., Bhowmick, S., Hiller, J. M.,

Betts, M., Principe, E. L., Jung, J.-Y., Sheppard, L., Wuhrer, R.,

McKittrick, J., Zavattieri, P. D. and Kisailus, D. (2016), "A Sinusoidally Architected Helicoidal Biocomposite". Advanced Materials, 28(32), pp. 6835-6844, 2016 [Download PDF]

- N Suksangpanya, NA Yaraghi, D Kisailus, P Zavattieri, "Twisting cracks in Bouligand structures", Journal of the Mechanics Behavior of Biomedical Materials, DOI: 10.1016/j.jmbbm.2017.06.010, 2017 [Download PDF]

Chiton/Rod-like structures:

- L.K. Grunenfelder, E. Escobar de

Obaldia, Q. Wang, D. Li, B. Weden, C. Salinas, R. Wuhrer, P.

Zavattieri and D. Kisailus, “Stress and Damage Mitigation from Oriented Nanostructures within the Radular Teeth of Cryptochiton stelleri", Advanced Functional Materials, 24(39), pp. 6085-6240, 2014 (DOI: 10.1002/adfm.201401091) [Download PDF][Cover Page]

- E. Escobar de Obaldia, C. Jeong, L.K. Grunenfelderb, D. Kisailus, P. Zavattieri, "Analysis

of the mechanical response of biomimetic materials with highly oriented

microstructures through 3D printing, mechanical testing and modeling", Journal of the Mechanical Behavior of Biomedical Materials, 48, pp. 70-85, 2015 (Top 3 Most Downloaded JMBBM Article - July 2015) [Download PDF]

- E. Escobar de Obaldia, S. Herrera, L.K. Grunenfelder, D. Kisailus, P. Zavattieri,"Competing mechanism in the wear resistance behavior of biomineralized rod-like microstructures", Journal of the Mechanics and Physics of Solids, 96, pp. 511-534, 2016. [Download PDF]

- C. L. Salinas, E. Escobar de Obaldia, C. Jeong, J. Hernandez, P. Zavattieri, D. Kisailus, "Enhanced toughening of the crossed lamellar structure revealed by nanoindentation", Journal of the Mechanics Behavior of Biomedical Materials, DOI: 10.1016/j.jmbbm.2017.05.033, 2017 [Download PDF]

NanoHUB tools: S Lee; C. Gomez, P. Zavattieri; A. Strachan (2011), "Bio Composite Simulator," DOI: 10254/nanohub-r12273.1. link: http://nanohub.org/resources/nacresimulator

|

|

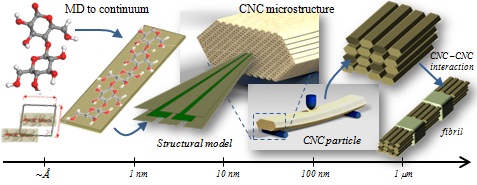

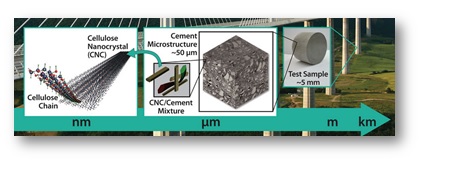

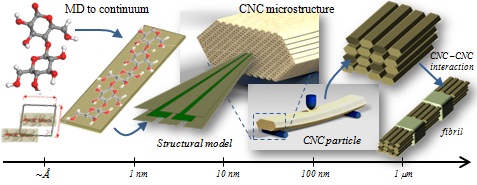

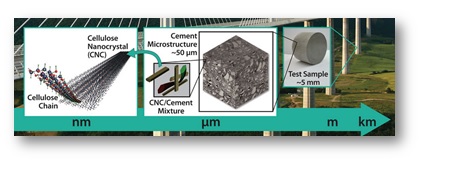

Nanomechanics of cellulose: Study

and characterization of the hierarchical structure-mechanical response

relationship of the cellulose nanocrystals (CNCs) to understand how they can

achieve their full potential for the new generation of green and

renewable materials. Development of new theories, novel multiscale

computational tools and continuum/discrete models to properly describe

and predict the mechanical behavior of cellulose nanocrystals.

Development of mesoscale nonlocal models for adhesion between

nanocrystals with strong connection to in-situ experiments with

application to the processing of cellulose-based

nanocomposites.

Collaboration with experimental and processing groups across

campus.

Current collaborators: Ashlie Martini, Robert Moon, Jeffry Youngblood and Jason Weiss

More information at the

NanoForestry Web site

Most relevant Papers:

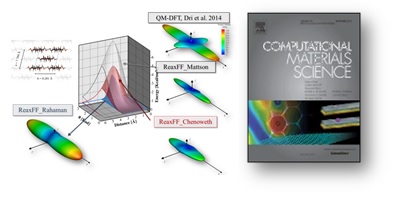

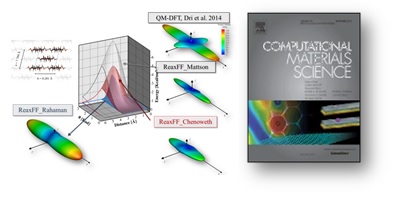

Modeling of Cellulose NanoCrystals (CNCs)

- F. Dri, L.H. Hector Jr., R. J. Moon,

P.D. Zavattieri,“Anisotropy

of the Elastic Properties of Crystalline Cellulose Iβ from First

Principles Density Functional Theory with Van der Waals Interactions”, Cellulose, 20(6), pp. 2703-2718, 2013. [Download PDF]

- F. Dri, R. Moon, P. Zavattieri, ”Multiscale Modeling of the Hierarchical Structure of Cellulose Nanocrystals”, in Production and Applications of Cellulose Nanoparticles. Ed. M.T. Postek, R. J. Moon, A. Rudie, M. Bilodeau, TAPPI Press. (June 2013). [Download PDF]

- F. Dri, S Shang, L.G. Hector Jr,P. Saxe, Z-K Liu, R. Moon and P.D. Zavattieri, "Anisotropy and temperature dependence

- of structural, thermodynamic, and elastic properties of crystalline cellulose Iβ: a first-principles investigation", Modelling and Simulation in Materials Science and Engineering, 22 085012, 2014.[Download PDF].

- F.L. Dri, X. Wu, R.J. Moon, A. Martini, P.D. Zavattieri, "Evaluation of reactive force fields for prediction o fthe thermo-mechanical properties of cellulose Iβ", Computational Materials Science, 109, pp. 330-340, 2015 [Download PDF]

- M. Shishehbor, F. Dri, R. Moon, P. Zavattieri "A continuum-based structural modeling approach for cellulose nanocrystals (CNCs)”, Journal of the Mechanics and Physics of Solids, DOI: 10.1016/j.jmps.2017.11.006, 2017. [Download PDF]

NanoHUB tools:

- Mateo Gómez Zuluaga; Robert J. Moon; Fernando Luis Dri; Pablo Daniel Zavattieri (2013), "Crystalline Cellulose - Atomistic Toolkit," DOI: 10.4231/D35T3G03. Link: https://nanohub.org/resources/ccamt

- Mateo Gómez Zuluaga; Fernando Luis Dri; Pablo Daniel Zavattieri; Robert J. Moon (2013), "Anisotropy Calculator - 3D Visualization Toolkit," DOI: 10.4231/D3K06X13R Link: https://nanohub.org/resources/matrix2surface

- Kuo Tian, Mehdi Shishehbor, Pablo Daniel Zavattieri (2016), "Coarse Graining of Crystalline Cellulose", DOI: :10.4231/D3930NW4D. Link: https://nanohub.org/resources/cgmcc

- Joshua Leonardo, Mehdi Shishebor, Pablo Zavattieri, "Mechanics of Crystalline NanoCellulose Nanofilm", doi:10.4231/D3TT4FW0D, https://nanohub.org/resources/cnc

CNC/Cement Composites

- Y. Cao, P. Zavattieri, J. Youngblood, R. Moon, J. Weiss "The influence of cellulose nanocrystal additions on the performance of cement paste", Cement and Concrete Composites, 56, pp. 73-83, 2014. [Download PDF]

- Y. Cao, W.J. Weiss, J.

Youngblood, R. Moon, P. Zavattieri, “Performance enhanced cementitious

materials by cellulose nanocrystal additions”, in Production and Applications of Cellulose Nanomaterials. Ed. M.T. Postek, R. J. Moon, A. Rudie, M. Bilodeau, TAPPI Press. (June 2013). [Download PDF]

- Y. Cao, P. Zavattieri, J. Youngblood, R. Moon, J. Weiss, "The relationship between cellulose nanocrystal dispersion and strength", Construction and Building Materials, 119, pp. 71–79, 2016 [Download PDF]

- Y. Cao, N. Tian, D. Bahr, P.D. Zavattieri, J. Youngblood, R.J. Moon, J.Weiss, "The influence of cellulose nanocrystals on the microstructure of cement paste", Cement and Concrete Composites, 74, pp. 164-173, 2016. [Download PDF]

|

|

|

|

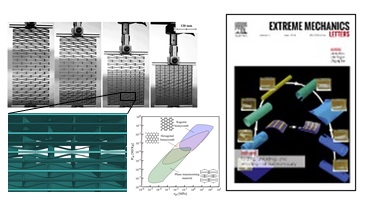

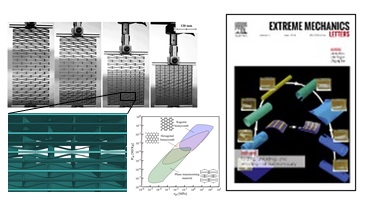

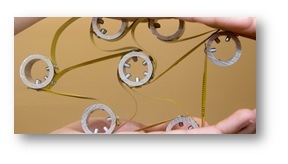

Multi-functional cellular materials with programmable properties:

Design

and analysis of active-material based periodic cellular

microstructures to obtain materials that have the capability

to (1)

change and adapt their key macroscopic properties to certain changes in

the loading and environmental conditions (switchable/adaptable

mechanical properties), (2) to adapt their shapes to new configurations

(morphable and reconfigurable surfaces and structures), (3) exert

forces and induce motion for specific tasks (actuation). Study of adaptive materials with real-time

microstructural

control, patterned microstructures with controlled auxectic behavior

and self-adapatable materials.

Innovative energy absorbing materials have potential uses in buildings, helmets [Purdue Press][Phys.org]

Some videos: [Programmable Cellular Materials] [Phase Transforming Cellular Materials]

|

|

Most relevant Papers:

Phase Transforming Cellular Materials:

- D. Restrepo, N.D. Mankame, P.D. Zavattieri, "Phase Transforming Cellular Materials", Extreme Mechanics Letters, 2015 [Download PDF]

Programmable Cellular Materials:

- D. Restrepo,

N. D. Mankame and P. D. Zavattieri, “Shape Memory Polymer based

Cellular Materials”, Mechanics of time-dependent

materials and processes in conventional and multifunctional materials,

v. 3, Society for Experimental Mechanics , 2011.

doi:

10.1007/978-1-4614-0213-8_15.[Download

PDF]

- D. Restrepo, N. Mankame,

P. Zavattieri,"Programmable materials based on periodic cellular solids. Part I", International Journal of Solids and Structures, 100-101, pp. 485–504, 2016, 2016. [Download PDF]

- D. Restrepo, N. Mankame,

P. Zavattieri,"Programmable materials based on periodic cellular solids. Part II", International Journal of Solids and Structures, 100-101, pp. 505–522, 2016. [Download PDF]

|

|

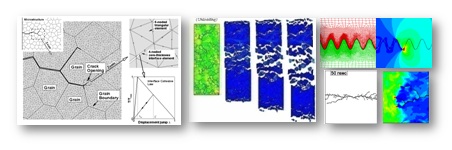

Areas of

Expertise:

Computational

Solid/Structural Mechanics: Modeling

of damage and fracture of advanced

materials. Micromechanics, fracture mechanics and interfacial fracture

mechanics. Development of micromechanical models for brittle and

composite

materials. Multiscale modeling of crack propagation and fragmentation.. Development and application of cohesive zone

models for the

simulations of mixed mode

I/III

fracture of thin-walled structures (including metals, polymers and

composites).

Development of novel

experimental/computational procedures

for determining fracture properties. Multiscale

modeling of interfaces. Analysis of

adhesively-bonded structures. Deformation and fracture

of spot welds.

Identification of deformation and failure of

composite materials at various

length scales. Multiscale modeling of nanocomposites and

determination of the interfacial properties of

nano-reinforcements/polymer

interfaces. Development

of adaptive mesh procedures

for modeling of large deformation and fracture in ductile materials.

Detailed

numerical analysis of ductile fracture in aluminum alloys, application

of

cohesive zone models for crack propagation. Discrete Dislocation

Analysis of

ductile fracture at the mesoscale.

|

|

Multiscale modeling of materials: Bridging

between atomistic models and continuum mechanics through mesoscale

modeling to allow a two-way structure - property relationship for the

prediction and control of materials functionality for a more efficient

non-Edisonian approach to material discovery. Development of

atomistically-informed constitutive models for deformation and failure

of materials to characterize the influence of defects in materials

across multiple length and time scales. Multiscale approaches that aim

to bridge relevant time and length scales. Development of scaling laws

to understand the synergetic role of size, geometry and material

properties. Emphasis on nanostructured periodic materials, nano-

and micro-patterned interfaces.

Patterned Interfaces:

- P.D. Zavattieri, L.H. Hector Jr., A.F.

Bower, “Determination of

the mode-I effective fracture toughness of a

sinusoidal interface between two elastic solids”, International Journal

of Fracture, 145 (3), pp. 167-180, 2007. [Download

PDF]

- P.D.

Zavattieri, L.H. Hector Jr., A.F. Bower,

“Cohesive zone simulations of crack

growth along a rough interface between two elastic plastic solids”,

Engineering Fracture Mechanics, 75(15),

pp. 4309-4332, 2008.[Download

PDF]

- F. Cordisco,

P.D. Zavattieri, L.H. Hector Jr., A.F. Bower, “Toughness of a patterned

interface between two elastically dissimilar solids”, Engineering Fracture Mechanics, 96, pp. 192-208, 2012. [Download PDF]

- F. Cordisco, P. Zavattieri, L.G. Hector, A. Bower ,“On the mechanics of sinusoidal interfaces between dissimilar elastic-plastic solids subject to dominant mode I", Engineering Fracture Mechanics , (DOI:10.1016/j.engfracmech.2014.06.004)[Download PDF]

- F.A. Cordisco, P.D. Zavattieri, L.G. Hector Jr., B.E. Carlson, "Mode I Fracture Along Bonded Sinusoidal Interfaces", International Journal of Solids and Structures, 83, pp. 45–64 2016. [Download PDF]

Crack Propagation in thin-walled structures:

- P.

Zavattieri, “Modeling of crack

propagation in thin-walled structures with a cohesive model for shell

elements”,

special issue on Computational Mechanics of Journal of

Applied Mechanics,73(6),

pp. 948-958,2006.

(Top 10 Most Downloaded

Articles -- October 2006) [Download PDF]

- M.A. Sutton, J.Yan, X. Deng. C.-S Cheng, P. Zavattieri,

“Three-dimensional

digital image correlation to quantify deformation

and crack-opening displacement in ductile aluminum under

mixed-mode I/III loading”, Journal of Optical

Engineering, 46(5), 051003, 2007. [Download PDF]

- J.-H

Yan, M. A. Sutton , X. Deng, Z. Wei and P. Zavattieri, “Mixed-mode

Crack

Growth in Ductile Thin-sheet Materials under

Combined In-plane and Out-of-plane

Loading” International

Journal of Fracture, 160(2), pp. 169-188 2009.[Download

PDF]

- J. Yan, M.

Sutton,

Z. Wei, X. Deng, P. Zavattieri, “Hybrid

Experimental and Computational Studies: Combined Compression-Bending

Fracture of Edge-Cracked Polypropylene Specimens”,

Fatigue and

Fracture

of Engineering Materials and Structures,

33(12),

pp. 791–808, 2010.[Download

PDF]

- Z.

Wei, X. Deng, M.A. Sutton, J. Yan, C.-S. Cheng, P. Zavattieri, "Modeling of Mixed-Mode Crack

Growth in Ductile Thin Sheets under Combined In-Plane and Out-of-Plane

Loading", Engineering

Fracture Mechanics, 78(17), pp. 3082-3101,

2011. [Download

PDF]

- X. Chen, X. Deng, M. A. Sutton, P. Zavattieri,“An Inverse Analysis of Cohesive Zone Model Parameter Values for Ductile Crack Growth Simulations", International Journal of Mechanical Sciences, 79, pp. 206-215, 2014. [Download PDF]

Adhesive Joints:

- S. Li, M.D. Thouless, A.M. Waas, J. Schroeder, P.D. Zavattieri,

“Mixed-mode

cohesive-zone models for fracture of an adhesively-bonded

polymer-matrix composite”, Engineering Fracture Mechanics,

73(1), pp. 64-78, 2006. (Most cited article in

the 2005-2009 period Award)

[Download

PDF]

- S. Li, M.D. Thouless, A.M. Waas, J. Schroeder, P.D. Zavattieri,

“Competing failure

mechanisms in mixed-mode fracture of an

adhesively-bonded polymer-matrix composite”, International Journal of Adhesion

and Adhesives, 26(8), pp. 609-616, 2006. [Download

PDF]

- S. Li, M.D. Thouless, A.M. Waas, J. Schroeder, P.D. Zavattieri, “Use of

Mode-I cohesive-zone models to describe the fracture of an

adhesively-bonded polymer-matrix composite”, Composites Science and Technology,

65(2), pp. 281-293, 2005.[Download

PDF]

- Li, M.D. Thouless, A.M. Waas, J. Schroeder, P.D. Zavattieri, “Use of

a cohesive-zone model to analyze the fracture of a fiber-reinforced

polymer–matrix composite”, Composites Science and Technology,

65(3-4), pp. 537-549, 2005. [Download

PDF]

- Sun, M.D. Thouless, A.M. Waas, J.A.

Schroeder, P.D. Zavattieri “Ductile-brittle

transition in the fracture of plastically-deforming adhesively-bonded

structures.

Part I: Experimental

studies”,

International Journal of Solids and

Structures, 45 (10), pp.

3059-3073, 2008. [Download

PDF]

- C.

Sun, M.D. Thouless, A.M. Waas, J.A.

Schroeder, P.D. Zavattieri “Ductile-brittle

transition in the fracture of plastically-deforming adhesively-bonded

structures. Part II: Numerical

studies” International

Journal of Solids and

Structures, 45 (17), pp. 4725-4738, 2008. [Download PDF]

- C.

Sun, M.D. Thouless, A.M. Waas, J.A.

Schroeder, P.D. Zavattieri, “Rate

Effects for Mode-II Fracture of Plastically Deforming,

Adhesively-Bonded

Structures", International

Journal of Fracture, 156(2), pp. 111-128, 2009. [Download

PDF]

- C.

Sun, M.D. Thouless, A.M. Waas, J.A.

Schroeder, P.D. Zavattieri, “Rate

Effects for Mixed-Mode Fracture of

Plastically Deforming, Adhesively-Bonded Structures," International

Journal of Adhesion and Adhesives, 29, (4), pp.

434-443, 2009.[Download

PDF]

|

|

|

|

|

[Complete list of publications]

Funding: - NSF

- AFOSR

- Joint Transportation Research Program (INDOT)

- Forest Product Laboratory (USFS)

- General Motors Reserach and Development

- Velcro

- Purdue Research Foundation

- Network for Computational Nanotechnology (NCN)

|

|

Home | Research | People |

Publications | News | Media |

Teaching | Contact

us

© 2017

Pablo D. Zavattieri | Site designed by P. Zavattieri

|