Shown below are general specifications of our capabilities across many facilities at Maurice J. Zucrow Laboratories. For details on equipment associated with each research area, visit our Research Areas page.

Find information on our facility's quality standards on our Quality Commitment page.

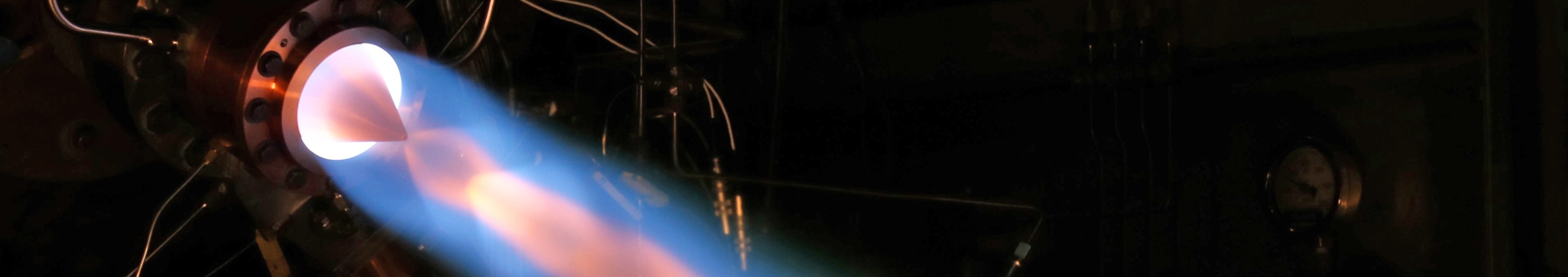

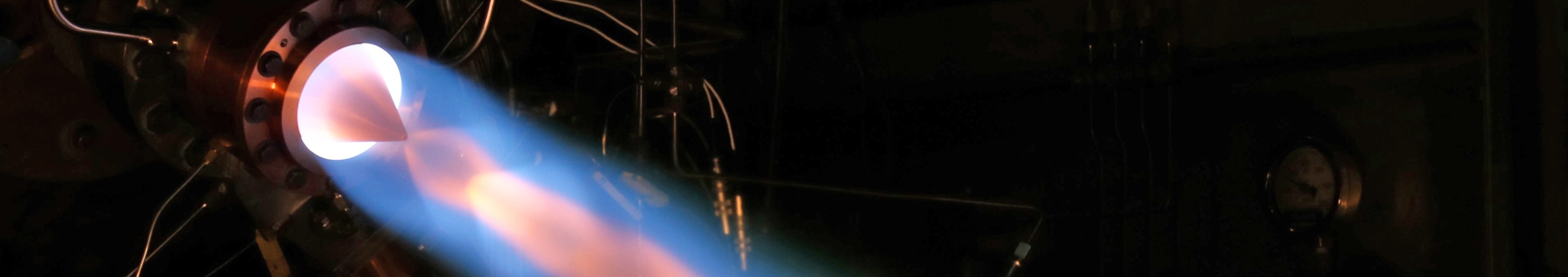

Propulsion

Propulsion

We can test and evaluate many types of propulsion systems at flight scale and in flight conditions. We also support combustion device development. We support testing with open storage at secret level security clearance.

Our tools include:

-

Multiple propulsion test cells with dedicated control rooms and diagnostics laboratories.

-

Chemical mixing and curing capability for solid fuels.

-

Test stands with axial and multi-component force measurement systems, maxing at 10,000 lbf.

-

On-site machine shop, welding services, and assembly spaces.

Data Acquisition & Control

Data Acquisition & Control

Using NI PXIe hardware with LabView:

-

312 analog input channels - 16-bit at 2 kHz per channel

-

96 on/off valve control channels with deterministic auto-sequence control at 1 msec resolution

-

32 analog output controls– 16-bit channels with deterministic auto-sequence control at 1 msec

-

Redline monitor of any & all data channels with programmable abort sequences

Using high-speed data acquisition by NI PXIe hardware with LabView at 2M sample/sec/channel simultaneous:

-

20 channels of Pacific Instruments signal conditioning

-

12 channels of PCB signal conditioning

Flow System

Flow System

-

High pressure air plant produces a continuous 5 lbm/s at 3,400 psi.

-

Air heating at 30 lbm/sec to 1,500° F at 800 psi

-

9,000 ft3 air storage volume, manifolded to support 400 lbm/s total flow in blow-down mode.

-

150,000 lbm air storage at 3,400 psi initial pressure

-

Approximate test times operating vitiating air heater and diffuser-ejector

-

600 seconds for 3X Direct-Connect

-

180 seconds for 10X Direct-Connect

-

120 seconds for 1X Free-Jet

-

Storage volumes of oxygen, nitrogen, hydrogen, and other fuels support or significantly exceed run durations set by air system

-

Electrical power supply available for up to 3 MW fuel heating capacity

Fluid Delivery Capabilities

Fluid Delivery Capabilities

Systems include:

-

Robust GOX/hydrogen or methane torch ignition systems

-

Computer control of pressure setpoints in all propellant systems and in independent high-flow capacity purge systems

|

Fluid |

Pmax

[psia]

|

Tmax

[F]

|

ṁmax

[lbm/s]

|

|

Oxygen |

3000 |

Ambient |

30 |

|

Nitrogen |

6000 |

Ambient |

20 |

|

Hydrogen |

6000 |

Ambient |

3 |

|

Natural Gas |

3600 |

Ambient |

3 |

|

Liquid Fuels |

5000 |

1000(+) |

1 |

|

Water |

1000 |

Ambient |

55 |

|

Clean, Heated |

800 |

1500 |

30 |

|

Vitiated, Heated |

1000 |

3000 |

100 |

|

Clean, Unheated |

3400 |

Ambient |

400 |

Gas Turbine Combustion

Gas Turbine Combustion

Our facilities support gas turbine combustion analysis at cycle-relevant conditions.

Current facilities support research and testing at engine cycle conditions with a single injection site.

-

8 MW steady-state thermal power

-

600 psi P3

-

1,400 F T3

Multiple test rigs provide optical access to the flow, including flame zone and inlet/exit boundary conditions. Features include:

-

Water-cooled internal surfaces

-

Film-cooled windows

-

Optical access for measurements of gas properties and wall conditions

Traditional probe-type instrumentation is also frequently incorporated, including:

-

Emissions sampling

-

Acoustics

Additive Manufacturing

Additive Manufacturing

Our capabilities range from formulation development, 3D printer machine design and modification, additive manufacturing of samples, and characterization of combustion and mechanical properties. Specifically, we have:

-

FlackTek DAC 515-200 PRO SpeedMixer

-

Vacuum oven 4.5 cu ft

-

Ender 3 V2 printers (FFF)

-

Prusa SLS 1 printer (SLA)

-

Prusa i3 MK3S+ (FFF outfitted with sensors and data collection system)

-

MFP printer (Dual VAP heads on an Ender 5+ printer gantry)

-

DMP printer (One VAP and one FFF head on an Ender 5+ printer gantry)

-

Filabot EX2 filament extruder

Data Acquisition & Control

Data Acquisition & Control Propulsion

Propulsion Flow System

Flow System Fluid Delivery Capabilities

Fluid Delivery Capabilities  Gas Turbine Combustion

Gas Turbine Combustion Additive Manufacturing

Additive Manufacturing