Office of Naval Research - Fan Casing Treatment (ONR)

|

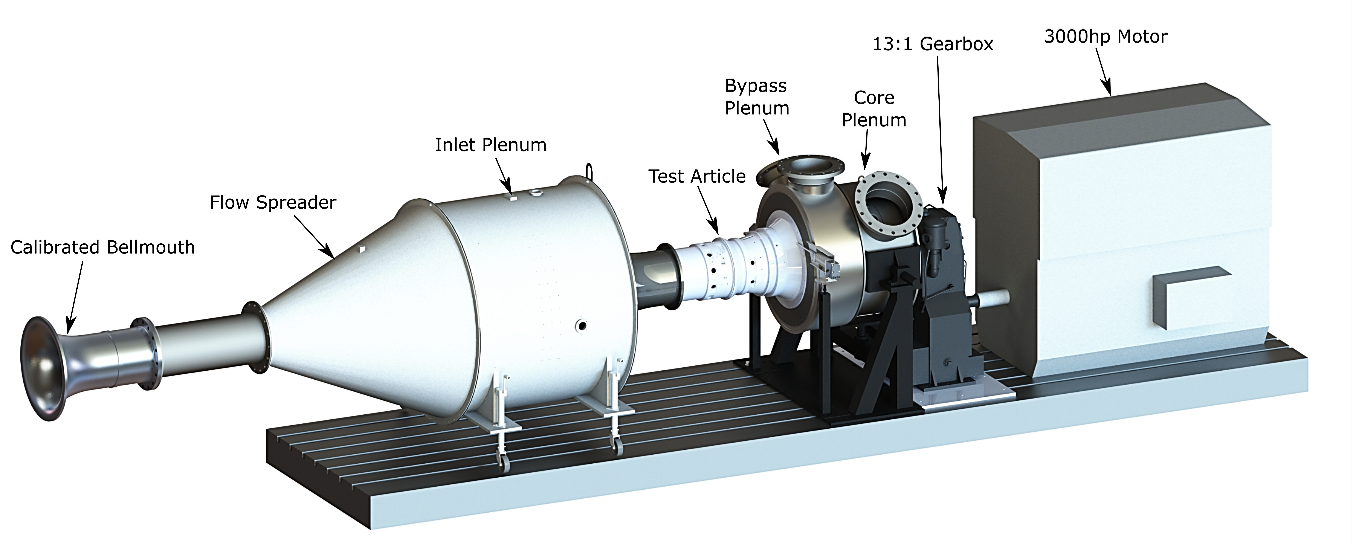

The Purdue Compressor Lab has recently acquired a fan designed by Honeywell Aerospace for use in a variety of research projects. The machine is a scaled down version of the fan stage from one of Honeywell’s proprietary engines. The design speed of this fan is 19,000 rpm, putting the aerodynamics associated with the blades in the transonic flow region. The research that will be conducted on this machine is funded by the Office of Naval Research (ONR). Naval aircraft are subjected to a variety of unique operating conditions that require the engines to push the boundaries of stability and performance. Some of these operating conditions include takeoff from aircraft carriers, complex flight maneuvers, and high aerodynamic loading of fan blades. These conditions provide the impetus for studying inlet distortion, casing treatments and aeromechanics. |

|

Current work: To accommodate the new fan, the compressor lab has been expanded to add a build up area for all of the rigs, two new test cells, and two new dedicated control rooms for the test cells. The renovation is part of the research funded by ONR and the fan rig takes up one of the new cells. This test rig is currently in the build-up phase. Computational research has been conducted to observe flow physics, design casing treatments to be tested, and understand fan mechanical response - experimental validation and testing coming soon!

|

|

Coming Soon! |

Theses

|

Research Objectives

Research Objectives

Specific Instrumentation Capabilities

Specific Instrumentation Capabilities