3D Vision for Automated Tire Unloading

The goal of this project is to eliminate the safety hazards of human workers involved in tire unloading by automating this process using 3D vision system. Our system first collects range data of tires using structured-light scanning technology.

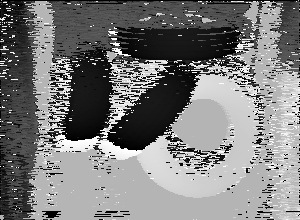

A range image contains depth value of each pixel represented by gray scale: the lighter gray scale the further the object is and vise versa. The range image of tires on the left contains much noise. This is due to the fact that a laser beam cannot be observed well when it is reflected on dark colored objects.

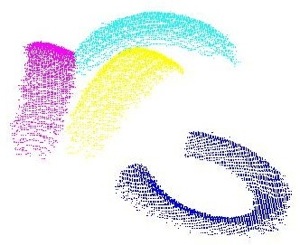

A range image can be converted to 3D points by a transformation matrix. A transformation matrix is computed during a system calibration.

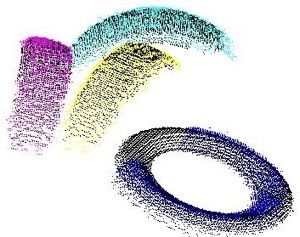

The next step is to separate each tire through a segmentation process. Different colored points represent each segmented tire.

Once we separate each tire, we need to distinguish each tire either as it was viewed from its tread side or as it was viewed from its side wall. We apply the PCA (Principle Component Analysis) for such a task.

The left picture shows the models (black points) appropriately assigned to each tire as either a tread or a sidewall. Also, the models are approximately aligned with its corresponding tire.

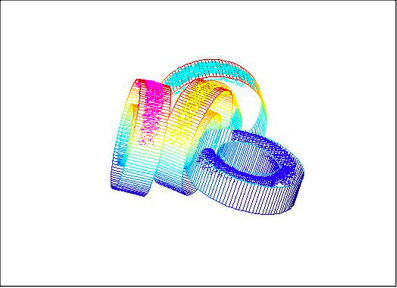

Then, we apply the ICP (Iterative Closest Point) based algorithm for final localization of tires by performing a final alignment between models and data. The left picture shows after performing the ICP algorithm.

The transformation matrix computed to align a model to each tire gives the exact position and orientation of the tire. The next picture shows the computed pose of tires by generating a tire like ring on top of the actual data points.