Facilities

Prof. Xu’s laboratories house state-of-the-art facilities including ultrafast laser systems and characterization equipment. The majority of Prof. Xu’s research facilities are located in the Birck Nanotechnology Center, with some in the building of the School of Mechanical Engineering.

- Two femotosecond laser-based 3D nanoprinters

- Projection multi-photon 3D nanoprinter using digital micro-mirror device

- 2 mJ chirlped pulse regenerative amplifier femtosecond laser

- High precision femtosecond laser micro-machining workstation

- Nanolithography system using optical antenna array

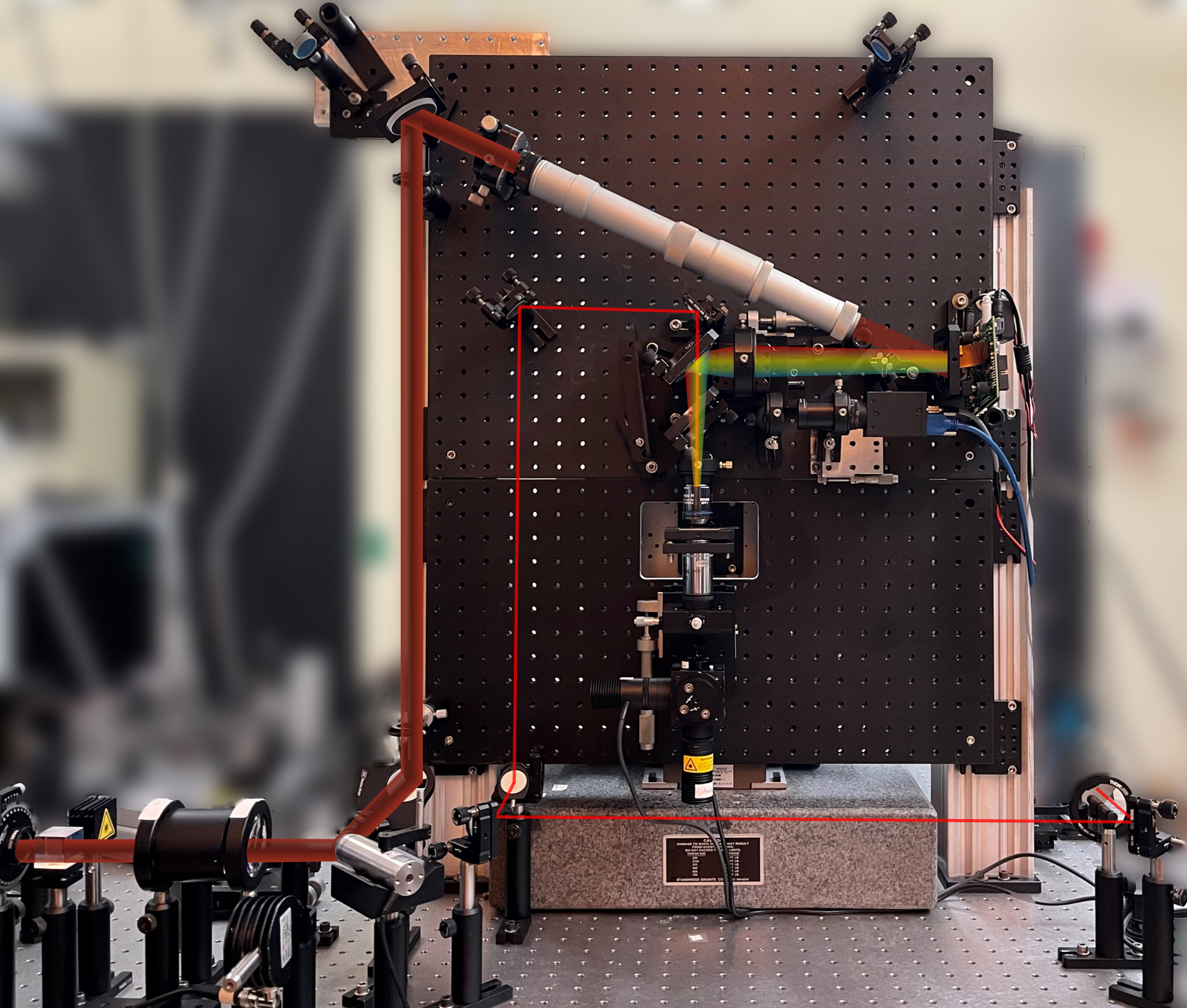

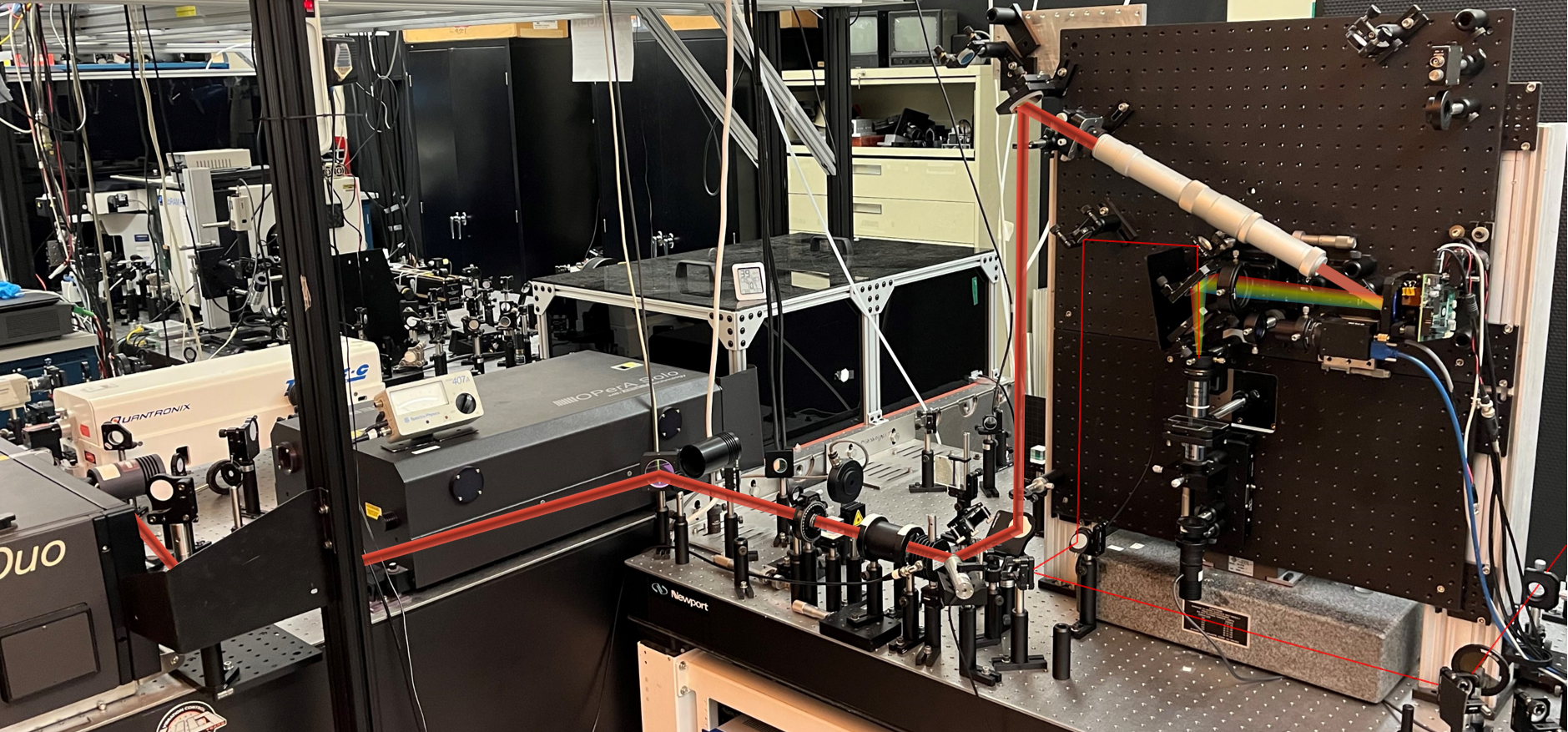

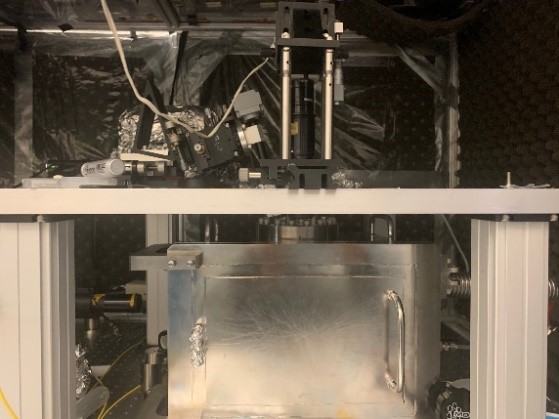

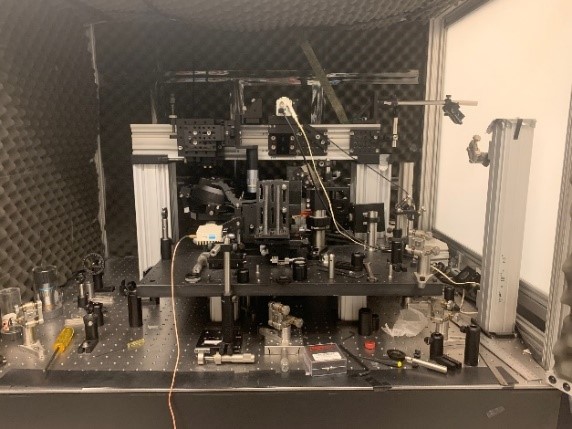

Image on the left shows our continuous, rapid multiphoton projection 3D printing system. Image below shows entire system from output of regenerative amplifier.

-

Two optical paramatric amplifiers, wavelength tunable from UV to IR

Two optical paramatric amplifiers, wavelength tunable from UV to IR - Pump-probe lines for femtosecond time-resolved measurements including TDTR

- Temporal pulse shapers for pulse shaping and coherent control studies

- Nanosecond laser thermal reflectance measurement apparatus for measuring thermal conductivity and contact resistance

Image on the right shows our ultrafast time-domain thermoreflectance system for thermal characterization of materials.

- Chemical vapor deposition (CVD) system for growing silicon nanowires and carbon-based nanomaterials

- Home-built AFM and NSOM with wavelength extended to near-IR (~1.8 micrometers) and coupled to FTIR

- Fourier Transfer Infrared (FTIR) Spectrometer, coupled with an IR microscope

- Other equipment such as a Raman Microscope, single shot auto-correlator, lock-in amplifiers, shakers, etc.

- Computational facilities including small clusters in the group and access to Purdue central computational

- A test rig for testing the performace of thermoelectric generator (TEG)

|

|

| Nanoscale radiation apparatus | Near-field scanning optical microscope (NSOM) |

|

|

| Fourier Transform Infrared (FTIR) Microscopy | Raman Spectrometer (LabRAM800) |

Group members have access to the clean-room micro/nano fabrication and characterization facilities in the Birck Nanotechnology Center, including focused ion beam (FIB), electron beam lithography, SEM, and TEM.

TEG Test Rig

A test rig for TEG performance evaluation has been built at Purdue University. It consists of heated gas supply for simulating waste heat source, a cooling loop, and a data acquisition system. It is capable of measuring the performance (power output) of individual TE module in a TEG, as well as the overall TEG performance including the energy conversion efficiency. Key capabilities:

- Heated gas supply with 24 kW heater, mass flow control units, power control units, and pressure transducers, capable of varying the gas temperature according to the actual transient temperature of, e.g., the automobile exhaust gas.

- Cooling loop with refrigerated circulating bath, heater, flow meter, and cold side heat exchanger to maintain a uniform coolant temperature under varying heat loads from the hot gas, coolant temperature maintained between -30oC and 135oC.

- Data acquisition system including precision electronic loads, each with 80 V, 60 A, 400 W capability, 10 mV, 1 mA, and 10 mW resolution, and 20 mV, 30 mA, and 80 mW minimum accuracy, 32 channel thermocouple inputs, 40 differential voltage channels, 2 analog and 24 digital output channels.

- Measurements of current-voltage and current-power curves of individual TE modules, tracking maximum power output from individual TE modules and the entire TEG by varying external loads, and measurements of hot gas and cold flow pressure drop.

Test rig overview

Gas supply

Data acquisition system